Reduce Incidents and Improve Operational Efficiency

Heavy Goods Vehicle (HGV) movements carry higher risk, tighter tolerances, and bigger consequences than car traffic. Two simple pieces of hardware can dramatically reduce incidents and improve operational efficiency in yards and loading bays: wheel guides and wheel stops. They do different jobs, and choosing correctly (or combining them well) is the difference between smooth, repeatable manoeuvres and recurring near-misses.

Below is a clear, practical guide to what each device does, where each excels, the pitfalls to avoid, and how to choose the right solution for your site.

HGV Wheel Guides and HGV Wheel Stops What are they and how do they differ

HGV Wheel guides

Function: Wheel guides direct wheel alignment. They provide a funnel or channel that encourages the trailer or vehicle wheels to track into the exact path you want, helping drivers approach at the correct angle and distance from the bay or stand.

Typical form: Robust, curved or tapered steel sections fixed to the ground on both sides of a bay approach.

Primary purpose: Guidance and repeatability, not stopping force.

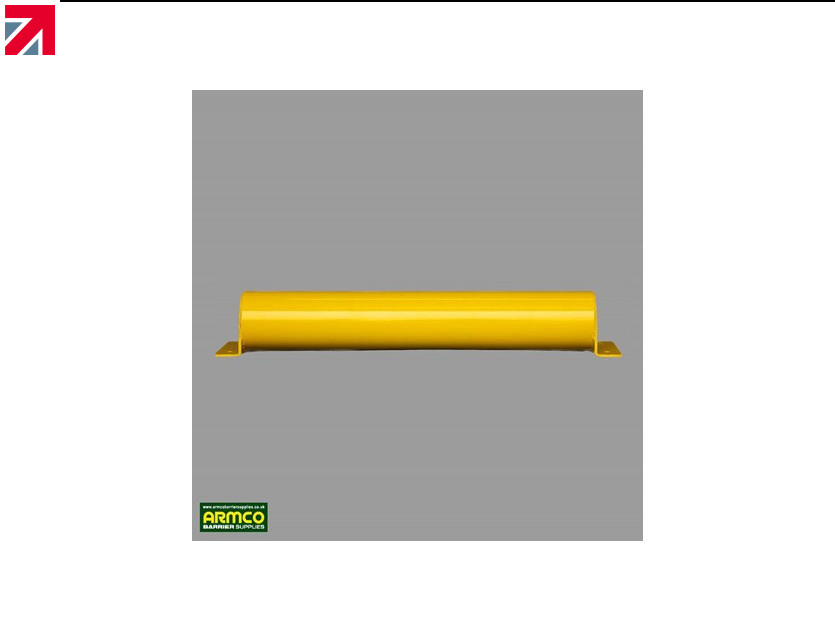

HGV Wheel stops

Function: Wheel stops stop a vehicle’s motion at a pre-set point. They provide a physical backstop so the driver cannot over-run a safe limit.

Typical form: Low-profile blocks or rails (rubber, composite, or steel) fixed to the ground, positioned to contact the tyres at a precise stopping line.

Primary purpose: Position control and overrun prevention, not guidance.

In short: Wheel guides steer you in; wheel stops hold you at the correct location.

When you need guiding vs when you need stopping

Choose wheel guides when:

- Approach alignment is inconsistent (tight yards, blind approaches, night operations, or poor weather).

- You need to protect bay infrastructure (dock shelters, levellers, buffers) from misaligned impacts.

- Multiple trailer types use the same bays and precise centring is required for seals and leveller lips.

- Throughput matters, guides reduce shunting time and driver hesitation.

Choose wheel stops when:

- There’s a critical safe limit (e.g., to prevent a trailer contacting a wall, overhanging a hazard, or encroaching on pedestrian routes).

- Dock equipment needs exact wheel position for leveller engagement or restraint operation.

- Gradient, momentum or tight tolerances risk overrun (sloped aprons, short aprons, or confined yards).

- Mixed driver familiarity, stops provide a simple, physical end-point for agency or visiting drivers.

Pros and cons of HGV Wheel Guides and HGV Wheel Stops

HGV Wheel guides

Advantages

- Improved alignment and first-time docking. Fewer corrective shunts; less time per arrival.

- Reduced infrastructure damage. Proper centring protects shelters, levellers and door frames.

- Better seal integrity. Correct alignment improves weather sealing and temperature control for chilled bays.

- Driver assistance under poor visibility. Night, rain, snow, or narrow approaches become more forgiving.

Limitations

- They do not stop the vehicle. If overrun is the hazard, guides alone won’t solve it.

- Space requirement. Need adequate apron width; can complicate sweeping or snow clearance if poorly placed.

- Trip/impact potential for pedestrians and MHE if sited near walkways or turning forklift routes.

- Maintenance. Bolts can loosen; paint and reflectors need upkeep; deformation possible if struck side-on.

HGV Wheel stops

Advantages

- Positive, repeatable stop point. Minimises overrun and protects structures directly behind the stop line.

- Consistent stand-off distance. Useful where doors, levellers or restraints require a set gap.

- Simple driver cue. A tactile feedback through the wheels communicates “you’re there”.

- Compact footprint. Easier to retrofit where apron width is limited.

Limitations

- No approach correction. Misaligned vehicles can hit stops obliquely, causing tyre or stop damage.

- Placement sensitivity. Set too far forward/back and you’ll compromise equipment engagement or bay seals.

- Wear and tear. Rubber/composite units degrade; fixings loosen; steel can rust if not maintained.

- Drainage and debris. Stops can trap litter or water if not detailed with cleaning in mind.

Can (and should) HGV Wheel Stops and HGV Wheel Guides be used together?

Often, yes especially in loading bays. A common best-practice layout:

- Paired wheel guides at the bay throat to capture the trailer wheels and centre the approach.

- A wheel stop set to the correct stand-off from the dock face to prevent overrun.

This pairing delivers both alignment and position control, reducing strike damage, speeding up docking, and improving safety for pedestrians and banksmen. The key is correct detailing: ensure the stop location works with your dock leveller reach, restraint geometry, shelter compression, trailer lengths, and yard gradient.

Application scenarios

General distribution loading bay (mixed trailer fleet)

- Primary need: Consistent centring and reliable stop point.

- Recommended solution: Wheel guides + wheel stop. Guides to reduce shunts and seal wear; stops to protect the door line.

Cross-dock with high throughput

- Primary need: Speed and repeatability under time pressure.

- Recommended solution: Wheel guides as mandatory; wheel stops where overrun could damage the opposite wall, plant, or walkways.

Narrow yard with oblique approach

- Primary need: Correct entry angle; limited manoeuvring.

- Recommended solution: Taller/extended wheel guides with tapered entries; consider a stop if structures are at risk.

Fuel, chemical, or high-hazard stand

- Primary need: Absolute position control and containment protection.

- Recommended solution: Wheel stops precisely positioned; wheel guides added if misalignment risks impacting pipework or bollards.

Open yard parking grids

- Primary need: Orderly parking, aisle protection.

- Recommended solution: Wheel stops to hold axles off walkways, light poles, or canopies. Guides are typically unnecessary unless bays are very tight.

Specification and design considerations

- Materials & profile:

- Wheel guides: Hot-dip galvanised steel is common; consider height and flare to suit HGV tyre diameters.

- Wheel stops: Steel tube for heavy-duty or snowplough areas, Rubber/composite for tyre-friendly contact

- Foundations & fixings: Use suitable anchors for concrete aprons; avoid fixing into poor or cracked slabs. For asphalt, detail concrete pads.

- Visibility: High-contrast paint, reflective bands or integrated markers aid night docking.

- Clearances: Maintain adequate lateral clearance to landing legs, side guards, and trailer skirts.

- Drainage & cleaning: Detail gaps for water runoff and sweeping. Avoid creating litter traps.

- Maintenance plan: Periodic torque checks, repainting, reflector replacement, and inspection after impacts.

- Operations interface: Align positions with dock leveller lip length, vehicle restraints, bay seal compression, and typical trailer wheelbases.

HGV Wheel Stops & Wheel Guides Cost and lifecycle

HGV Wheel guides generally have a higher upfront cost and installation complexity than stops but yield ongoing savings via reduced bay damage and quicker turns.

HGV Wheel stops are lower cost to deploy widely but may require more frequent replacement depending on material and environment.

A lifecycle view (capex + downtime + damage reduction) often favours guides where alignment errors are frequent, and stops where overruns are the dominant risk—with the combined solution prevailing at busy docks.

Find out more about Armco Barrier Supplies on their member profile page here

Member-created content 1 week ago | From members