1t Drop Hammer Piling Rig RPR DH10.3

Manufactured by Advanced Mini Piling Systems Ltd

Product Buying Options

Product Capacity: Capable of installing 150 m a day with favourable ground conditions.

Additional Sales Information: Please see our website for more details and options. Website: https://minipilingsystems.co.uk/rpr-dh10-3/ Email: sales@minipilingsystems.couk Call: 07771631187

Product Description

The DH10.3 is a Micro Pile Free-fall Rig/Drop hammer Rig in the RPR range (Remote Piling Rig) of Drilling, Piling, and Drop hammer machines manufactured by Advanced Mini Piling Systems Ltd in the UK.

- The DH10.3 is a Radio remote operated automatic piling rig. With all functions controlled from the operator's portable control unit.

- With rapid production on-site in mind, the DH10.3 is designed to raise its hammer over a 3.0 m steel cased pile.

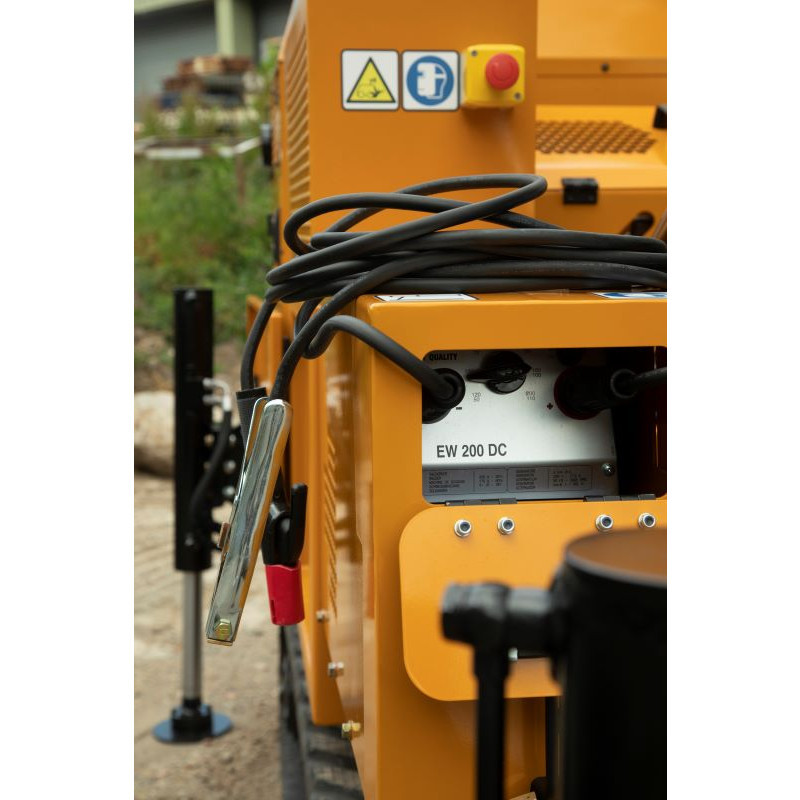

- The DH10.3 has an onboard 200A hydraulic welder that, unlike many competitors, our welder will run continuously. So while the operator is driving a pile, the welder can carry on welding casings from a safe distance of 20 m. Saving service costs, fuel and lugging another piece of equipment around site.

- With safety our main focus while designing the DH10.3 our emergency stop system attains BS EN ISO 13849-1:2015 performance level C.

- The Synergic Free-fall System is a computer program developed by ourselves. That is algorithmically controlled so as the hoist height increases the free-fall automatically adapts to suit.

- We have designed and tested our automatic free-fall system that reduces operator fatigue and increases on-site productivity. Our early R&D into this system has on some sites logged over 2000 drops in a single day. Which has an impact on the operator and increases wear on manual directional control valves.

- Manual free-fall control. If automatic control is not your thing, but still require user comfort. The free-fall system can also be actuated by the radio remote control.

- The DH10.3 comes with a 1-year warranty. And JCB engine warranty of 1 year minor parts & 2-years major parts.

- Extended wire rope life. We are continually investigating how to make our machines more economical, and wire rope life is an important factor in drop hammer rigs. Downtime due to changing ropes costs money. So, we have increased our sheave size and using our recommended ASTM A1023 Cat 1 rotation-resistant rope, our machines will have less downtime due to rope wear.

- Forecast wire rope changes. Our computer controlled free-fall systems record each free-fall cycle and winch pressure overload. This allows the owner to change the wire rope before the event of failure, saving downtime on-site.