Based in Melbourne, Australia, Additive assurance specializes in (L-PBF) Laser Powder Bed Fusion techniques and provides process monitoring and quality control for 3D printed components. But with years working in the AM industry, Additive Assurance experienced recovery problems with powder sieving.

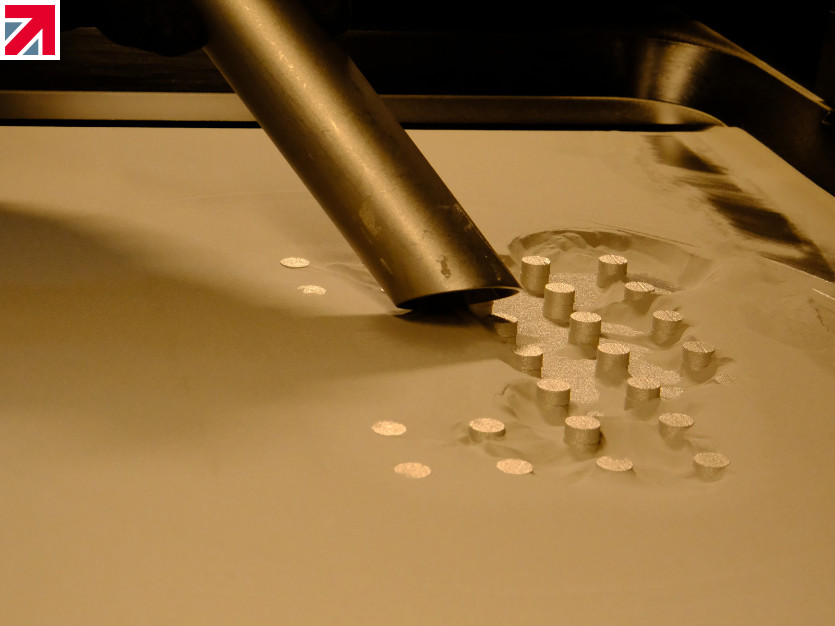

After the build is complete, the post-processing of L-PBF Additive manufacturing typically involves manual removal and sieving of the reclaimed powder. This proves to be a time-consuming, labor-intensive procedure that not only decreases productivity but also heightens the likelihood of powder exposure to operators.

After installing the Russell AMPro® Sieve Station, there is no need for full-time operators. Application engineers, responsible for overseeing the process, can simultaneously manage the 3D printer due to its short cycle time. Additive Assurance has seen a significant 60 to 70% decrease in cycle time compared to manual powder recovery methods. The Russell AMPro® Sieve Station can clear all unused powder from a build job in under ten minutes.

“The AMPro Sieve Station makes life so much easier. The vacuum conveyor system and the sieving operation are an enormous time saver, so we need less headcount for our operations. I can’t emphasize enough its usability benefits for us.” said Marten Jurg, Co-Founder and CEO

About Russell Finex

Founded in 1934, Russell Finex designs and manufactures sieving machines for a range of

industries. With its head office in the U.K. and subsidiaries in Belgium, the U.S.A., India, Brazil,

and China the company supplies to over 140 countries. Contact Russell Finex today to find out

more about its range of sieves, separators, and filtration equipment.

Find out more about Russell Finex on their member profile page here

Member-created content 1 year ago | From members