British manufacturer reimagines internal hatch access with a purpose-built, technician-friendly solution.

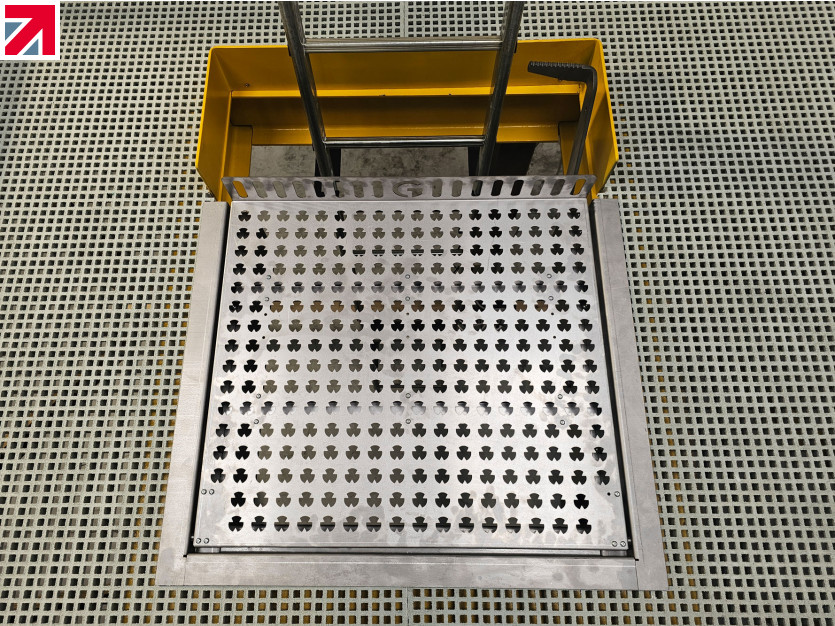

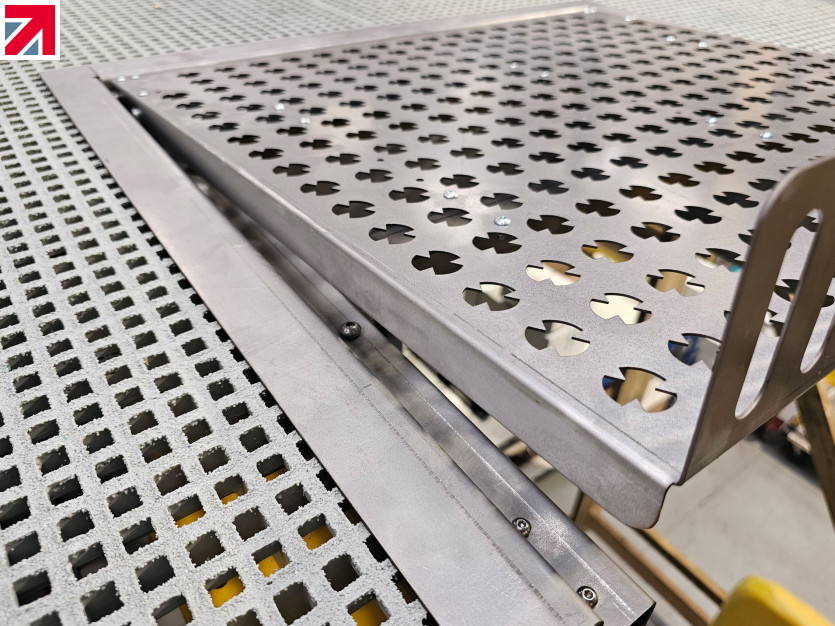

Gatemaster Offshore, a UK-based manufacturer specialising in access solutions for harsh environments, has launched its latest innovation: a Foot Operated Hatch Opener (FOHO), designed to improve safety and reliability in vertical access systems within offshore wind turbines.

For the past three decades, Gatemaster has been designing and manufacturing access hardware from its facility on the South Coast of England. Known for producing durable, practical solutions trusted by engineers and safety professionals, Gatemaster Offshore brings this expertise to the offshore and energy sectors with a focus on user-centric design, British engineering, and rigorous testing.

Built for Real-World Safety Challenges

In offshore wind environments, safety isn’t optional—it’s critical. Technicians navigating confined turbine towers face a range of hazards, including fatigue, wet surfaces, and challenging weather. One often-overlooked risk? The internal access hatches used between turbine platforms.

Traditional hatch systems rely on pulley mechanisms, weights, or awkward manual operation—all of which can create unnecessary risks. Recognising these shortcomings, Gatemaster Offshore developed the FOHO to be a self-closing, foot-operated hatch designed to eliminate the most common failure points.

“Technicians need equipment that supports them, not something they have to fight against,” said Jacob Napthine, Managing Director at Gatemaster Offshore. “We listened to feedback from the field and developed a hatch that is safer, simpler, and easier to install and maintain.”

Designed, Manufactured, and Tested in the UK

Manufactured entirely in the UK, the FOHO has been cycle-tested over 10,000 times to ensure consistent performance across the lifespan of a turbine. Its foot-operated design allows engineers to maintain three points of contact while ascending ladders—improving safety and reducing the risk of slips or falls.

The unit is supplied as a one-piece, drop-in system with a patent-pending clamping mechanism, making it fast to install and easy to service, even in space-constrained environments.

“UK manufacturing is at the heart of what we do,” added Jacob Napthine. “By keeping production local, we maintain tight quality control, reduce lead times, and provide customers with reliable, robust products built to meet the demands of modern industry.”

Adaptable Across Multiple Sectors

While the FOHO was developed with offshore wind turbines in mind, the technology has far wider applications. From utility infrastructure and energy installations to water treatment and industrial platforms, any environment requiring safe vertical access can benefit from this innovative hatch.

Available in multiple sizes and configurations, the FOHO is both a standardised and adaptable solution that meets a wide range of engineering requirements—while retaining the core principles of safety, durability, and ease of use.

About Gatemaster Offshore

Gatemaster Offshore is part of Gatemaster Locks, a leading UK manufacturer of gate hardware and access systems with 30 years of industry experience. Drawing on decades of engineering expertise, Gatemaster Offshore delivers purpose-designed, high-performance solutions for demanding environments including offshore, marine, and energy sectors.

As a proud Made in Britain member, Gatemaster Offshore is committed to quality UK manufacturing, innovative product design, and improving safety standards across industrial access systems.

Discover More

To learn more about the Foot Operated Hatch Opener or to request a specification sheet, visit: gatemasteroffshore.com

Designed, Manufactured, and Tested in the UK

Manufactured entirely in the UK, the FOHO has been cycle-tested over 10,000 times to ensure consistent performance across the lifespan of a turbine. Its foot-operated design allows engineers to maintain three points of contact while ascending ladders—improving safety and reducing the risk of slips or falls.

The unit is supplied as a one-piece, drop-in system with a patent-pending clamping mechanism, making it fast to install and easy to service, even in space-constrained environments.

“UK manufacturing is at the heart of what we do,” added Jacob Napthine. “By keeping production local, we maintain tight quality control, reduce lead times, and provide customers with reliable, robust products built to meet the demands of modern industry.”

Find out more about Gatemaster Ltd on their member profile page here

Member-created content 4 months ago | From members