Creating custom solutions for transport and storage has become a significant part of the workload at Jordan Metalwork more recently, but one project has stood out as particularly exciting and rewarding.

The Norfolk based team were tasked with fabricating a custom transportation system specifically for satellite components. These components required secure transport in and out of clean rooms at the production facilities. To meet the unique demands of the project, the components needed to be anodised to ensure any foreign particles picked up in the clean room could be easily identified.

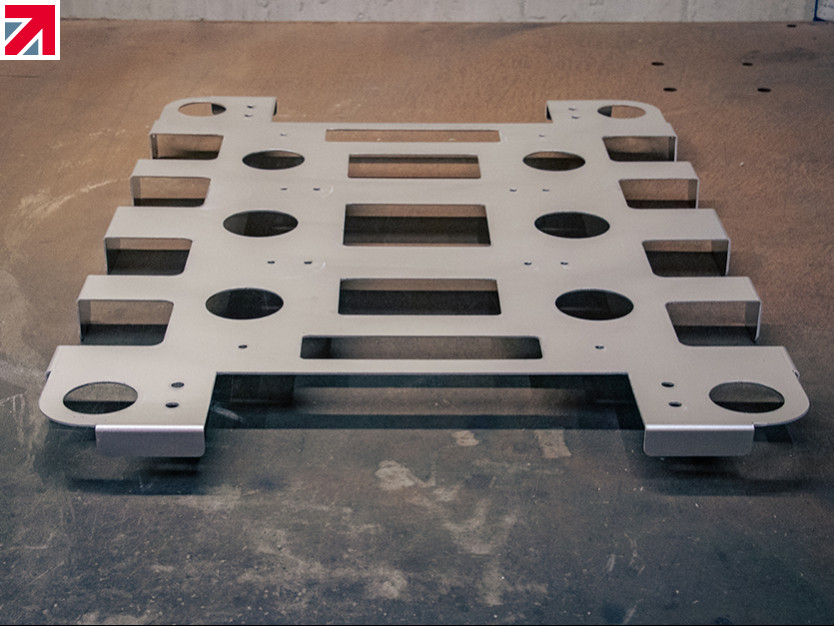

Measuring approximately 700mm x 500mm, the fabrication process began with laser-cutting the design from flat sheets of steel. Next the press brake was used to fold the necessary parts and the CNC milling machine created the precise posts required. Finally, the entire system was anodised to meet the stringent cleanliness and identification requirements.

While these transport cases won't be journeying into space themselves, they play a crucial role in safely moving components that are essential for constructing satellites—satellites that will ultimately embark on their missions beyond Earth.

Zak Pitt, Managing Director commented "As the demand for innovative space technologies grows, we are thrilled by the opportunity to contribute to projects like this and hope to be involved in even more space-related endeavours in the future."

If you're interested in learning more about Jordan Metalwork's bespoke transport solutions or need custom fabrication services for your next satellite launch or any other project, don’t hesitate to get in touch. They would love to help you tackle your next metalwork challenge!

See more and contact the team at www.jordanmetalwork.com

Find out more about Jordan Metalwork on their member profile page here

Member-created content 5 months ago | From members