For over 75 years, Thame Workholding has been a trusted supplier across a wide range of industries. Through our extensive network of partnerships, we provide comprehensive solutions for nearly all standard workholding requirements. However, some applications demand a more specialised, engineered approach—an area where Thame Workholding excels.

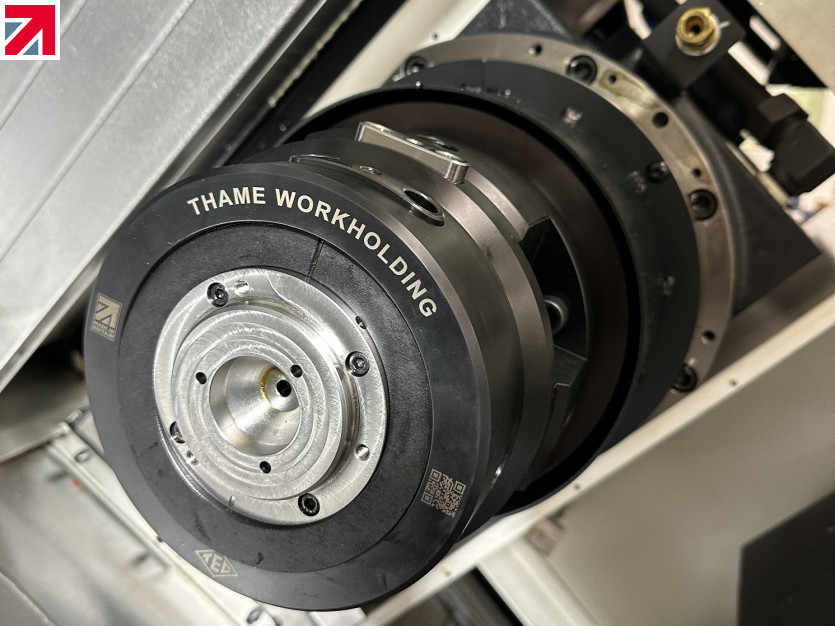

One such innovation is the Magic Chuck, a highly refined bespoke workholding solution designed specifically for machining acetabular liners in the medical industry. The inception of the Magic Chuck arose from a fundamental shift in the machining process due to product design advancements, rendering traditional methods unsuitable. Tasked with developing an alternative, Thame Workholding engineered an innovative approach to securely hold the part without introducing distortions associated with conventional gripping techniques. The solution? Vacuum workholding.

Collaborating closely with both the product owner and machine tool suppliers, Thame Workholding engineered a system that addressed not just the immediate machining challenge but also the broader considerations of component variability and cost efficiency. The Magic Chuck utilises modular, quick-change components to accommodate various part sizes without requiring excessive additional investment. The use of vacuum technology ensures secure holding without introducing undue mechanical stresses that conventional chucks might impose.

Beyond secure clamping, the Magic Chuck also overcomes the challenge of off-axis machining. By leveraging the actuation cylinder of the machine tool, the system enables precise pivoting, allowing for parts to be turned off axis at a specific angle, generally on the sub-spindle enabling pats to be machined complete without human intervention, something no other workholding solution on the market can achieve with the same level of accuracy and efficiency.

The engineering ingenuity of the Magic Chuck extends beyond the fixture itself. Thame Workholding provides a complete, turnkey solution, including a control cabinet, vacuum pump, coolant separation system, and all necessary I/O interfaces and monitoring capabilities, ensuring reliability and efficiency in operation.

With cutting-edge innovation and precision engineering at its core, the Magic Chuck truly lives up to its name—delivering unparalleled workholding performance for complex medical components.

Find out more about Thame Workholding on their member profile page here

Member-created content 6 months ago | From members