What Is a Roller Conveyor? How They Work, Why They Matter

A roller conveyor is a type of material-handling equipment designed and built to use a series of rollers mounted on a frame to transport goods from one point to another. An important piece of equipment for any warehouse, manufacturing plant, packaging line, or distribution centre. These conveyors are favoured for their efficiency and reliability in moving a wide variety of items — from light cartons and parcels to heavy pallets and crates.

You can find our full article here - 'What is a Roller Conveyor', and you can find more information about roller conveyors on our roller conveyor page.

How do Roller Conveyors Work?

The basic principle behind roller conveyors is simple: items placed on the rollers move in the direction the rollers spin. Rollers can be powered by gravity, manual push, or electric drives. Without the rollers spinning, the conveyor functions like an ordinary table.

Roller conveyors come in two main types:

These systems rely on gravity (or a gentle manual push) to move items along the rollers. Because there is no motor driving the movement, these are cost-effective and relatively simple to install and maintain. They’re ideal for straightforward transfers of medium to light loads in a flat or gently sloped layout. Sometimes these conveyors are used to manually push items along.

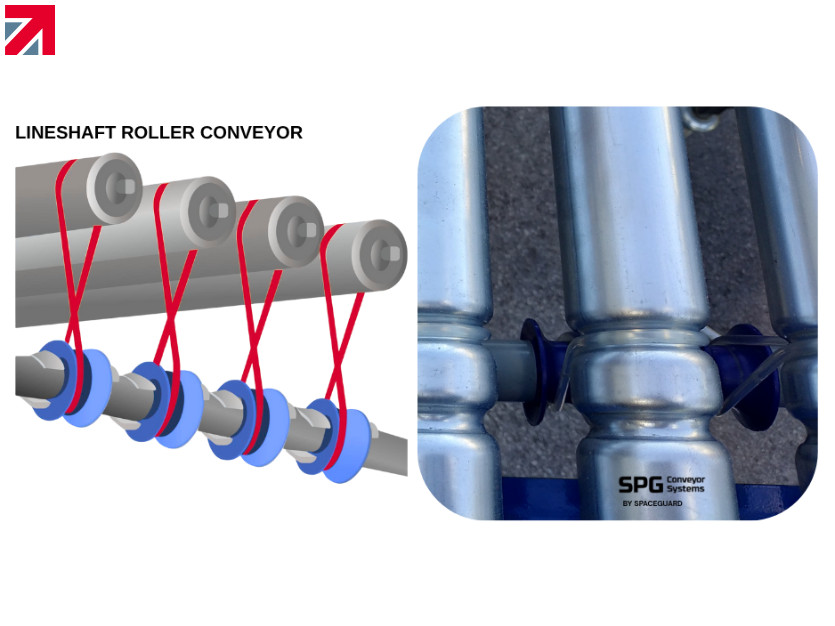

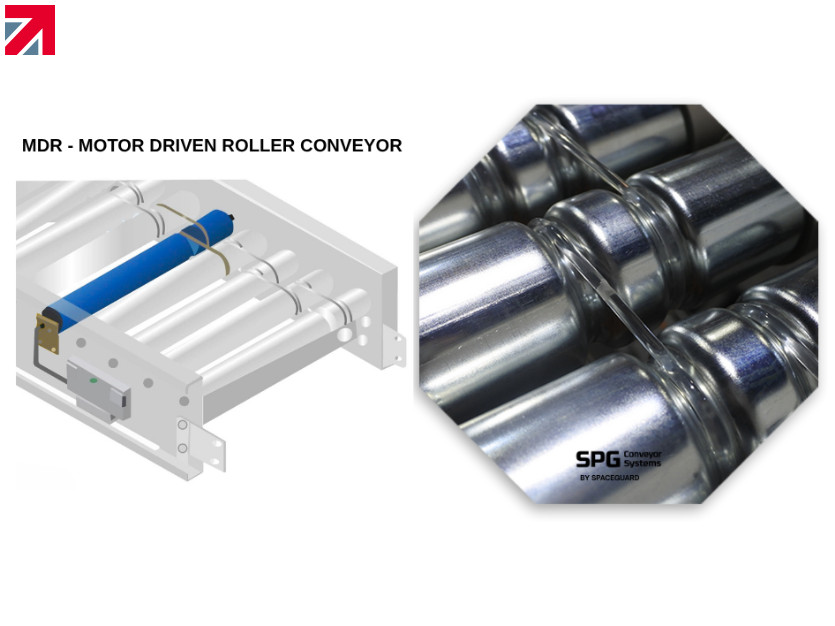

Driven Conveyors / Electric Drives

In these systems, one or more rollers are powered (via motorised shafts, belts, or chains) to provide controlled, consistent movement. This makes them suitable for heavier loads, automated systems, varying speeds, accumulation zones, or integration with sorting/packing lines. The diagrams below show two example diagrams of motor-driven conveyors and lineshaft conveyors.

Why are Roller Conveyors so commonly used?

- Versatility

They handle different product types — cartons, crates, trays, pallets — and adapt easily into production lines, packing areas and logistics zones.

- Durability

With minimal moving parts (especially in gravity systems), the conveyors tend to be robust, low-maintenance and reliable over time.

- Efficiency in material flow

By automating part of the transport process inside your workspace, they reduce manual handling, cut down on labour costs and improve safety.

- Customisation potential

Whether you require a standard roll-through system or a bespoke configuration (e.g., multi-zone driven rollers, accumulation, incline/decline sections, specialist frames or drives), these conveyors can be engineered to suit your process.

- Space optimisation

With modular framing and flexible layouts, these conveyors integrate well into many environments — helping you streamline product movement without massive floor-space expansions.

If you require a conveyor that’s built around your process — not the other way around, let’s talk!

📞 01482 363445

📧 sales@conveyorsystems.co.uk

Find out more about Spaceguard Ltd on their member profile page here

Member-created content 1 day ago | From members