Ava May Aromas is a young, inspiring producer of heavenly scented wax melts and candles. Their vegan-friendly and cruelty-free handmade products are complemented with reed diffusers and room sprays, all available in a range of dupe scents inspired by popular designer fragrances.

Like many artisan brands, owner, Hannah Chapman, began making handmade scented candles in the kitchen of her parents’ house. Soon after introducing wax melts into the mix, the business began to take off - a steady increase in online followers and orders, took the company into its first new production facilities in Andover, Hampshire.

With the range expanding, the company needed to start batch-coding their products. They had already invested in new staff, as well as product branding and quality packaging, but with orders nearing 20,000 per month, they knew they needed to find an automated way to add labels and codes to products.

Finding the right entry-level batch-coding solution

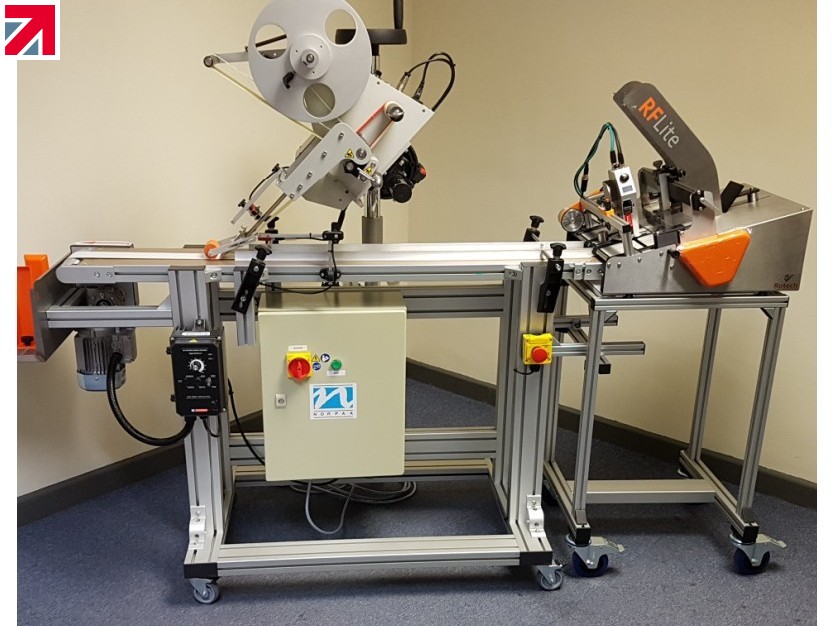

Initially, the company installed a Norpak labeller which automatically applied product labels to packaging. Knowing that the company were looking for a handheld printer to apply batch codes, Norpak referred the team to Rotech Machines. Sales manager and printing specialist, Steve Ryan, visited their facilities initially to demonstrate the handheld printer, however, it was soon clear that they needed a more flexible, future-proof solution.

“When we made our first visit to demonstrate our handheld printer, we discovered that they actually had a variety of different packaging designs including small pocket pouches, small boxes, boxes with clear casing and shipping boxes. Using a handheld printer could lead to inconsistent printing and ultimately it would be more time-consuming.” said Steve. “Being new to coding, we helped them to see how they could very easily automate the entire process of applying codes, and integrate it with their labeller”.

We returned to give them a demonstration of the RF Lite, an entry-level sleeve and carton feeder that is specifically designed for businesses looking to code their packaging for the first time. Small and flexible, it allows them to simply stack their cartons and pocket packs and automatically print batch and date codes directly onto their packaging using an integrated Integra One thermal inkjet printer.

For added flexibility we showed them how they could use the coding system independently or integrate it with their Norpak conveyor system, allowing them to code and label products.

The team were so impressed that they subsequently ordered two RF Lites so that they could use each method. In order to apply batch codes directly to their larger outer boxes, they ordered a further printer which was fitted to a slider rig, giving them even greater coding flexibility.

Applying coded labels to clear case packaging

Wax melts are one of Ava May Aroma’s most popular products. They sell 27 different varieties of scents in single pillow boxes or clear case multi-packs. To apply labels to the clear cases, the packaging is fed along their Norpak labelling conveyor, however, they needed to be able to apply a batch code to the label.

To achieve this, we mounted an Integra printer directly onto the labeller using a simple, fully adjustable frame; the batch code can then be printed directly to each label before it is applied to the product.

Read the full case study here

Daryl Chapman, company director at Ava May said “We now have four Rotech batch coding devices. We received our first one approximately 2 months ago and were very impressed with the performance. Having just gone through a complete rebrand of our products and packaging, we found further need for the coding machines, some of which we needed to work in conjunction with our automated packing machines. The Rotech salesman Steve was full of good advice and we consequently ended up purchasing 3 more batch coders.

We had an issue recently where we needed technical support. After working with an engineer over the telephone to resolve the issue, Rotech decided to send an engineer to us the following morning. It turned out that the coder had a technical fault and the company replaced it with a new system there and then. Not only that, the engineer then checked our other coders and made several changes to improve performance. This was a service par excellence.

Rotech were actually recommended to us and I would have no hesitation in recommending them on to others who are looking to automate their operations.”

Find out more about Rotech Machines Ltd machines here

Find out more about Rotech Machines Ltd on their member profile page here

Member-created content 5 years ago | From members