In 2011 Swift-Cut set out to be a global leader in the design and build of high quality, affordable CNC plasma cutting machines. They succeeded – and Made in Britain member Wrights Plastics has played a part in their remarkable growth.

For over 10 years they have manufactured a wide range of high-quality covers for many of Swift-Cut's sector-leading machines. The partnership has worked for a decade because of shared values of quality and innovation, as well as an ongoing commitment to UK manufacturing.

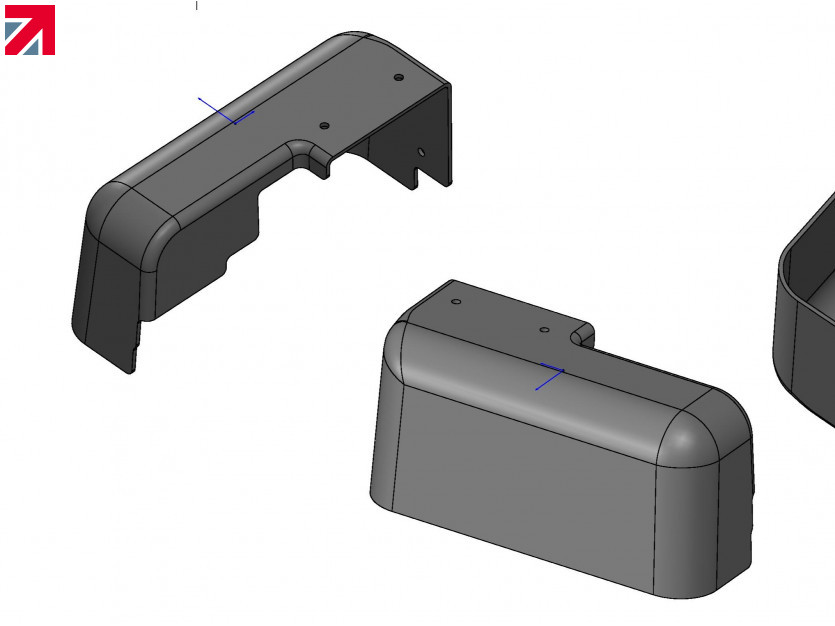

With the plasma arc delivering eye-watering temperatures the first essential for all the parts manufactured is safety. With their extensive material credibility, Wrights Plastics work with fire retardant materials to produce covers that offer outstanding protection even in the harshest manufacturing environments. Their cable covers for example need to protect against molten debris.

All the machine guards and covers are vacuum formed by their expert teams, and they use a variety of inhouse finishing processes including 5 axis CNC. Call off orders can run to several thousand parts – this is where Wright's large capacity and flexible working offer the ideal service for Swift-Cut.

The relationship continues with the West Bromwich-based acrylic fabricator developing new tooling for new covers for new machines being developed by Swift-Cut.

Find out more about Wrights Plastics Ltd on their member profile page here

Member-created content 1 year ago | From members