Sophisticated technical ceramic materials have transformed the world we live in. They are present in vehicle sensors and control systems, within our computers, phones and touch pads, and the water and power we use daily all benefit from ceramic technologies, which can resist the extreme temperatures and mechanical stresses in applications for generating energy in power plant engines and turbines, all contributing to better efficiency and productivity.

The unique properties of these numerous ceramic components can make them a difficult material to manufacture to the required specification. Many are made from the same material that historically would have been utilised to lap and polish them; typically aluminium oxide and silicon carbide.

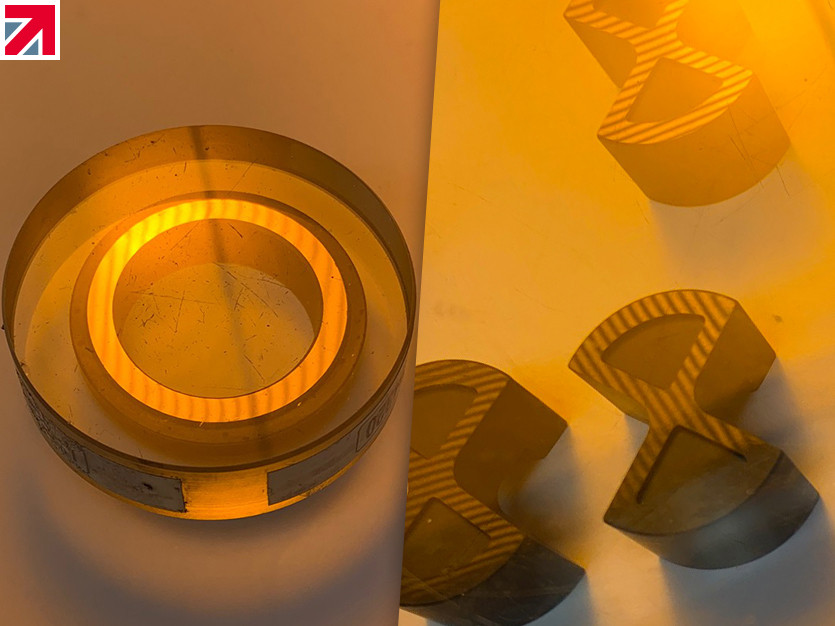

This was a challenge that Kemet International was able to rise to with their Kemet lapping plate material combined with diamond compounds and slurries. Originally developed in the 1970s, this combination of composite lapping plate and diamond abrasives made the lapping and polishing of ceramic materials much more efficient with results that enabled 100% quality control as a by-product of the highly reflective surfaces that this process combination was able to achieve. Until this breakthrough Boron Carbide had been the only option for lapping ceramic materials and this was a very costly and incredibly messy process producing a non-reflective surface that was difficult to measure optically.

Kemet has a complete process programme which includes diamond slurries for use with both twin plate and open-face lapping machines, Kemet composite plates designed specifically for certain types of ceramics, as well as uniquely formulated cast iron plates. Ceramic coatings found on aerospace bearing assemblies have required the development of special purpose machines as well as process consumables, another of the great technical services Kemet can offer.

White alumina-based ceramics can be difficult to clean after a lapping or polishing process, particularly where cast iron has been used as a lapping tool. Typically, the oils and metal particles will contaminate the surface of these components, and without the right cleaning chemistry, can be difficult to revert the parts to their unique pure white appearance.

In these situations, Kemet’s Cleaning Division can provide the correct cleaning fluid, process and equipment needed for small batches, or thousands of parts, each solution tailored for your business.

If you are struggling with achieving the required surface finish for your ceramic process or application, contact Kemet for free trials with no obligation.

Find out more about Kemet International Ltd on their member profile page here

Member-created content 2 years ago | From members