Prototyping

Manufactured by Rutland Plastics

Product Buying Options

Additional Sales Information: Wherever possible, we aim to respond with a quote within 24 hours. You can have prototypes in your hands within 3-4 days of initial contact—sometimes faster.

Product Description

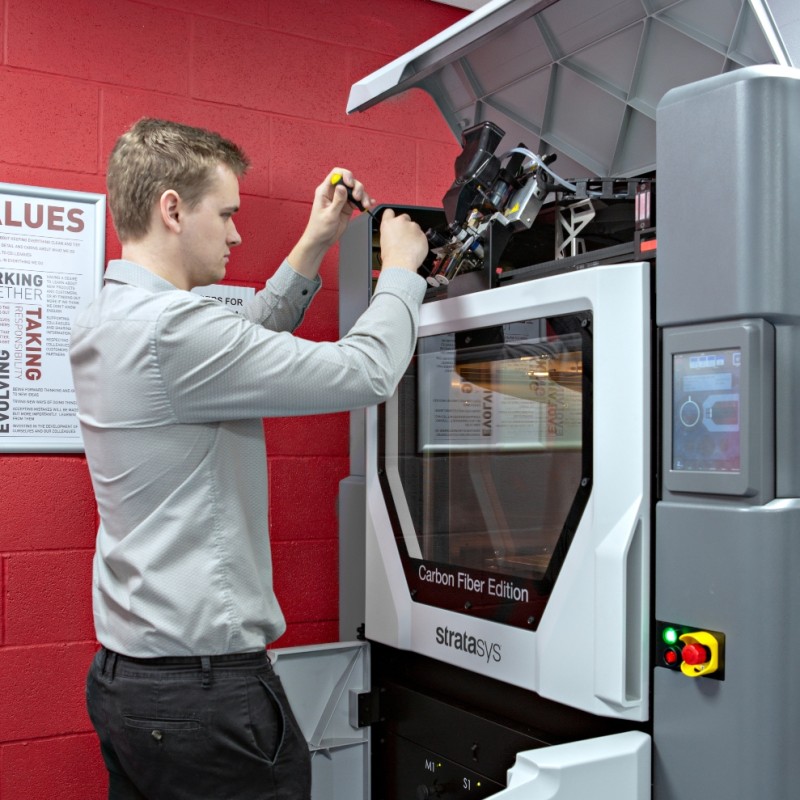

Using the toughest 3D-printing materials ever created, Rutland Plastics has the capability to produce rapid fully functional prototypes in-house for you to confidently test the functionality of your products prior to committing to the investment in a mould tool.

This advanced 3D production system prints with FDM Nylon 12 Carbon Fibre (CF) and ASA give unparalleled strength and stiffness to prototypes, and indeed low volume production parts, jigs and fixtures, plus end-of-arm robot tooling that we produce.

The Fortus system uses a wide range of thermoplastics with advanced mechanical properties so that your parts can endure heat, caustic chemicals and high impact applications, meaning carbon fibre printed prototypes are much more than typical printed prototypes used to validate form and fit, because of their incredible strength they can be fully tested for functionality just as an end-use part.