Buying printed circuit boards (PCBs) designed and produced by overseas manufacturers of course has its advantages – cost being the biggest and most obvious. Yes, PCBs made in countries like China can be kinder to your budget for the short term. But, in the long term, there can be serious questions asked about the durability, reliability and longevity of PCBs made overseas, which can have an impact on costs and reputation.

Today, more and more businesses are seeing the light when it comes to the quality, affordability and eco-friendliness of British-made PCBs. This made-in-Britain mentality is leading to a resurgence in businesses choosing home-grown PCBs. Leading the pack in championing locally-made PCBs are ourselves at ABL Circuits. With over 40 years of success in the industry, we know a thing or two about just how great a British-made PCB can be.

In this article, we’re going to highlight just some of the ways a made-in-Britain approach could just be what your business needs if you’re looking for high-performing, long-lasting and cost-effective PCB solutions.

Your search for reliable PCBs ends here

At ABL Circuits, we’ve been producing reliable and high-performing British-made PCBs at our Hertfordshire facility for more than three decades. We pride ourselves in using our wealth of experience and expertise to meet client expectations so you have everything you need from a PCB in the shortest possible time frame.

This places us as one of the go-to PCB manufacturers for businesses looking to reshore their supply chain and have less reliance on international suppliers. In fact, data shows that more than half of manufacturers have started to reshore supply chains, proving that there is an undeniable resurgence for made in Britain.

We’ve worked with organisations in the aerospace, automation, automotive, energy, healthcare and military and defence industries, designing and manufacturing PCBs for use in countless scenarios under some of the harshest conditions in the world. No matter what you need a PCB for, we can produce a final product that is strong, reliable, affordable and long-lasting.

The ABL Circuits difference: “made in Britain” advantages

Choosing a local supplier like ABL Circuits means you get plenty of made-in-Britain advantages:

Superior quality control: a dedication to excellence

Britain-based manufacturers understand that customers and clients demand quality, and PCBs can only have the highest quality if quality control and inspections are a key part of the process. We meticulously inspect PCBs at seven separate stages throughout the process to ensure quality and consistency are never compromised. Not only does this provide you with a better final product, but it means you’re more likely to come back to us for any future PCB needs – it’s a win-win scenario.

Faster turnarounds and unmatched flexibility

British-made PCB manufacturers with a focus on keeping the supply chain local ensure faster turnaround times and a far greater degree of flexibility. When PCBs are produced in the UK, it allows for simpler modifications and customisations, smaller batches, and more agility. Manufacturers that are based closer to home have shorter and less complex supply chains, meaning there are likely to be fewer disruptions, transportation delays and geopolitical tensions. This means you can be in receipt of your PCBs in next to no time – in our case, you can expect delivery within five working days.

Supporting the local economy: jobs, skills, and industry

Choosing a Britain-based PCB manufacturer means you’re supporting the local economy to stimulate economic growth and keep more people in the jobs they love. It helps keep Britain firmly in its place and ensures continued investment in this flourishing industry.

Environmental responsibility: a reduced carbon footprint

Customers and the government are becoming increasingly more conscious of the impact that work undertaken by various industries has on the environment. As a result, customers are seeking suppliers that share their eco-friendly mindset and the government is implementing guidelines surrounding emissions, energy use, waste and more.

When the supply chain is smaller, not only does it increase reliability, it decreases risk and the impact on the environment. Every business has a role to play in improving green manufacturing practices, and here at ABL Circuits, we do what we can to ensure sustainable PCB design and manufacturing.

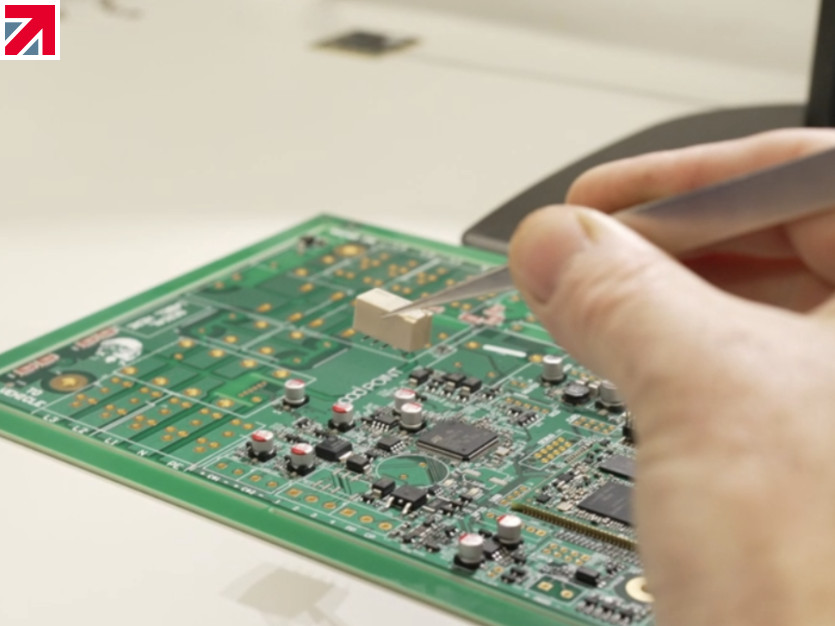

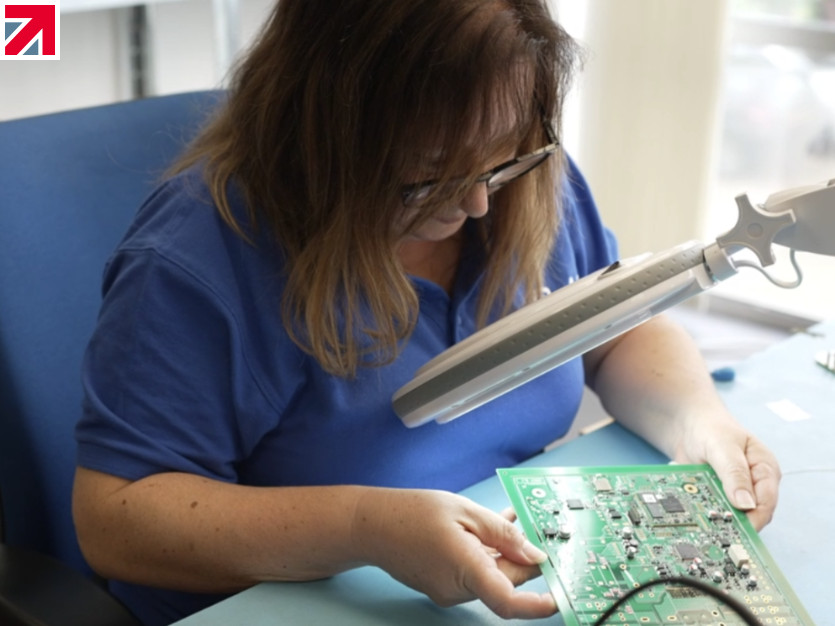

Inside ABL’s UK manufacturing facility

At ABL Circuits, here in our Hertfordshire-based facility our team of dedicated engineers use their skill and knowledge obtained over decades of experience, as well as state-of-the-art technology, to deliver consistently quality products to our clients. We have ISO 9001-2000 Accreditation, so you can be confident that you’ll receive a product that meets your expectations.

We use sustainable design and manufacturing practices to turn around orders within five working days – we also offer an eight-hour turnaround if you’re in quick need of your PCBs.

PCBs are tested at seven separate stages throughout the production process to identify and correct potential problems. Boards are also electronically bare board tested which ensures no shorts or opens.

At ABL Circuits, we’re committed to ensuring our British-made PCBs continue exceeding our customers’ expectations. We use an unbeatable combination of experienced and committed design, quality material and component selection, and sustainability best practices. This means we manufacture PCBs that are high-performing and reliable and last a long time operating in even the harshest environments.

Find out just how fast, affordable and dependable a UK PCB manufacturer can be. Get a free trial today and enhance your product with ABL Circuits.

Find out more about ABL Circuits Ltd on their member profile page here

Member-created content 1 year ago | From members