Amscreen GRP Manufactured Telephone Solution

AllScope Projects have developed a GRP solution for local multimedia provider Amscreen.

Amscreen provide urban environments across the UK with the tools they need to become the cities of the future.

Always looking to evolve their services and solutions, Amscreen required an alternative manufacturing solution for the production of their iconic telephone box with integrated multi-media advertising platform.

The 90 year old iconic telephone box, the ‘K2’, as been re-modelled and re-invented by Amscreen to maximise the potential of todays multi-media, technological world. Installed onto footpaths in major cities, the new and modern styled telephone box now includes high-speed Wi-Fi, digital advertising screens and touchscreen functionality.

Amscreen and AllScope Projects Supply Audit

Amscreen commissioned an internal audit to identify if there were was an improved solution to their existing manufactured unit. Improvements should increase lifespan longevity, enhance safety in a public setting, be more economical and eco-friendly to manufacture in the UK and maintain a stylish and modern aesthetically pleasing design.

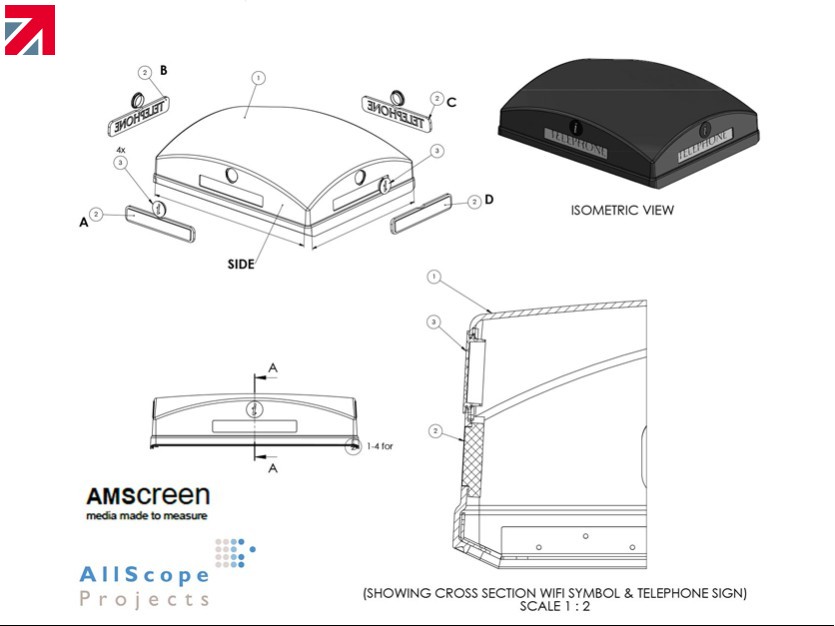

Amscreen then approached AllScope Projects for consultation and following a robust design, capability, material sourcing and manufacture review, appointed us to manufacture a safe, economical and practical solution to replace the existing lid on the main telephone box housing.

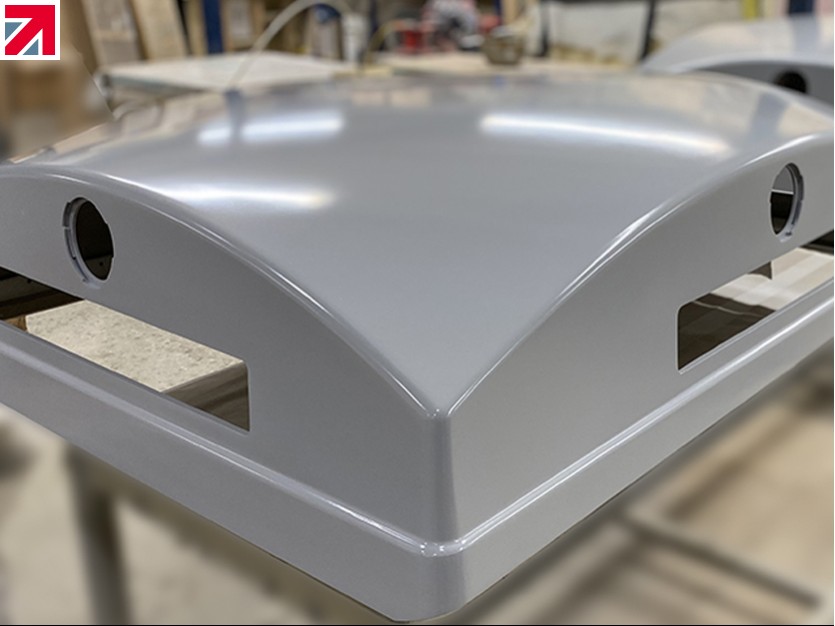

As the body of the telephone box had already been suitably manufactured, we worked closely with Amscreen to design a GRP solution that would ensure the lid fit perfectly on the body and demonstrate the many benefits of transitioning to a GRP solution.

The original lid was made of vacuum formed thermo softening plastic that required additional aluminium ribs to ensure suitable strength. This manufacturing process was time consuming, expensive and the materials used had a short lifespan, requiring on-going maintenance to prevent a weathered faded paint finish and damage from flying objects.

Technical Considerations

- To be suitable and safe for public realm, public highway positioning.

- To be fire retardant.

- To be of robust material to survive graffiti or damage.

- To align with existing main box unit in aesthetics and fit.

- To be able to house pre-manufactured illuminated signage, thereby reducing re-manufacture costs.

- To match metallic silver textured pain finish

Full Turn Key Solution Provided

AllScope Projects design and engineering team worked closely with the Amscreen to comply with design requirements and provide improvement suggestions to maximise investment, manufacture and delivery process.

The final solution delivered included:

- GRP: Due to its lightweight, robust, highly durable composition, there was no requirement for original aluminium ribs reducing production costs, materials and time.

- Fire Retardant: BS476 Part7 Class 2 standard fire retardant polyester GRP.

- Corrosive resistant GRP.

- Designed to specification to attach to main unit.

- Signage: Laser cut cores that created a repeatable moulded aperture, fixed into position on folded aluminium brackets with precision manufacture for extremely tight tolerances.

- Lid attachment to main unit: CnC laser cut precision alignment and folded brackets bonded to lid.

- Delivered to Amscreen Bolton depot

Manufacturing In NorthWest England

AllScope Projects Director of Operations Michael Davies explained the working practices of the project “Amscreen are local to us, just up the M65/M61 and so it was great to work with a local, forward thinking organisation looking to repurpose iconic designs and keep precision engineering and manufacture local to the Northwest”.

“This is the second K2 telephone box project we have worked on, following our support of the Childline Charity telephony box manufacture in London.”

Michael added “The team at Amscreen were pro-active and open to our suggestions, which enabled us to develop a solution that not only ticked their boxes, but also added value with our expertise in GRP composite design and manufacture.

Amscreen CEO Simon Sugar explained “Amscreen are delighted to be working with AllScope Projects to supply the lids to our multi-media phone boxes. Where possible, Amscreen will always prioritise working with and supporting local suppliers, and we are very pleased to be able to work with a forward-thinking organisations like AllScope Projects, based just down the road from us in Lancashire, in order to keep precision engineering and manufacturing local to the Northwest”.

Find out more about AllScope Projects on their member profile page here

Member-created content 3 years ago | From members