Losing money may be the biggest catalyst for change. For manufacturers utilising steam within their process, leaking steam traps along with the manual techniques used to maintain such systems, are proving to be a costly combination. Furthermore, the unrelenting increases in energy and gas prices have manufacturers’ backs up against the wall. In this article, we’ll address how manual monitoring is costing you thousands backed by findings in a steam trap survey and what actions are needed.

The breakdown in 2020

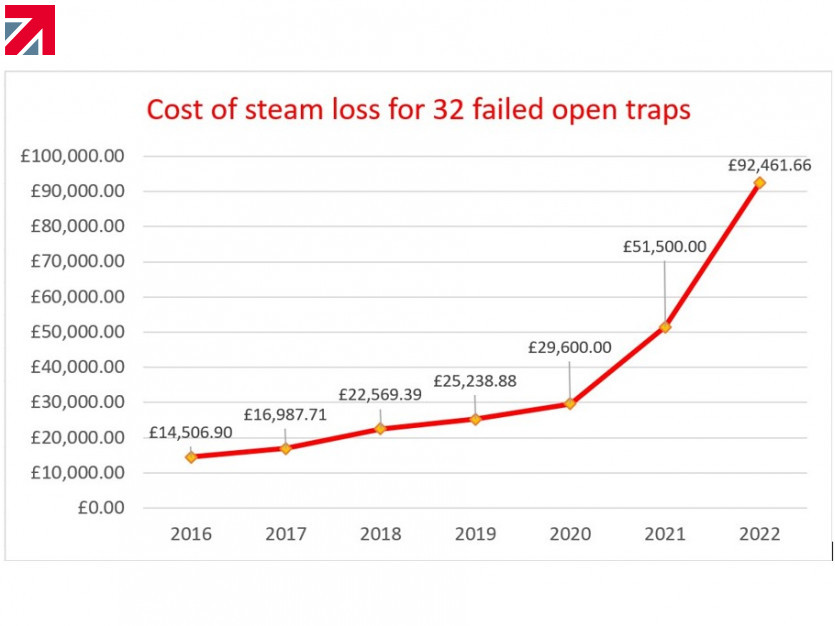

One site we’ll examine has nearly 400 steam traps of all different models, types, and sizes. Approximately 200 are located within a tunnel system that connects the infrastructure of the steam system. These are difficult to access and diagnose. Up until recently, the engineer overseeing the steam traps provided a scheduled yearly maintenance check on the traps along with an annual trap survey. Industry wide, it is estimated that 10% of steam traps will fail during the year. According to the steam trap survey conducted in the 2nd quarter of 2020, 32 traps failed open whilst 9 failed closed. The lack of continual maintenance meant that the trap leaks were moderate to severe. Because of this, the annual cost of energy losses from the failed open steam traps alone amounted to over £29,600. As indicated in the survey, the unit cost of fuel at that time (May 2020) was 2.44 pence. Furthermore, the amount of CO2 emissions from the failed traps amounted to over 200 tonnes per year.

The price increase in 2021

According to the Department for Business, Energy & Industrial Strategy, ‘Prices in the manufacturing industry continued to increase over 2021.’ The price for electricity in October to December 2021 was 15.14 pence per kWh and the price for gas was 4.25 pence per kWh. Based on the increase of fuel prices, 32 failed open traps amounted to £51,500 in energy losses in December 2021. That’s a staggering £21,900 more.

The cost reality of 2022

Now in the 2nd quarter of 2022, we are seeing gas and energy prices at the highest level recorded this century. As a result, leaking steam traps are becoming significantly more costly. However, even within the most difficult challenges, opportunities and solutions can be found. That’s the focus of the International Energy Agency’s article ‘What does the current global energy crisis mean for energy investment?'. It states, ‘The extraordinary financial windfall for the oil and gas sector from today’s high prices could provide a major boost to clean energy investment.' One affordable step in this direction is implementing a self-powering monitoring solution that identifies wasteful energy loss from steam traps. Because they are battery-free and wireless, their environmental impact is considerably less than battery-powered or wired-in sensors.

The ROI silver lining

Recently, the site described above contacted DCO Systems to monitor their 400 steam traps, with monitors starting at £180 each. DCO’s battery-free, energy harvesting sensors do not require cabling and can be easily installed throughout the entire site including the difficult to access tunnel system. The engineers now receive live data updates and alerts when leaks are small. Consequently, engineers can fix leaks immediately which combats expensive steam loss and produces savings on time and labour. Based on recent fuel prices at 7.62 pence per kWh, DCO’s monitoring system will yield a full Return on Investment after 8.7 months.

DCO Systems’ energy harvesting sensors utilise thermal, solar and electromagnetic sources that already exist in the environment to power themselves. They are allowing engineers to monitor more metrics in parallel and provide persistent, round the clock data on their steam traps. With unstable gas and electricity prices, this is an opportunity to move in a new direction. DCO Systems can help your company stop losing a fortune on leaking steam traps and CO2 emissions so you can invest those savings for future projects. To get started with DCO’s monitoring solutions, go to dcosystems.co.uk, email: info@dcosystems.co.uk or call: 01285 359059.

Find out more about DCO Systems Limited on their member profile page here

Member-created content 3 years ago | From members