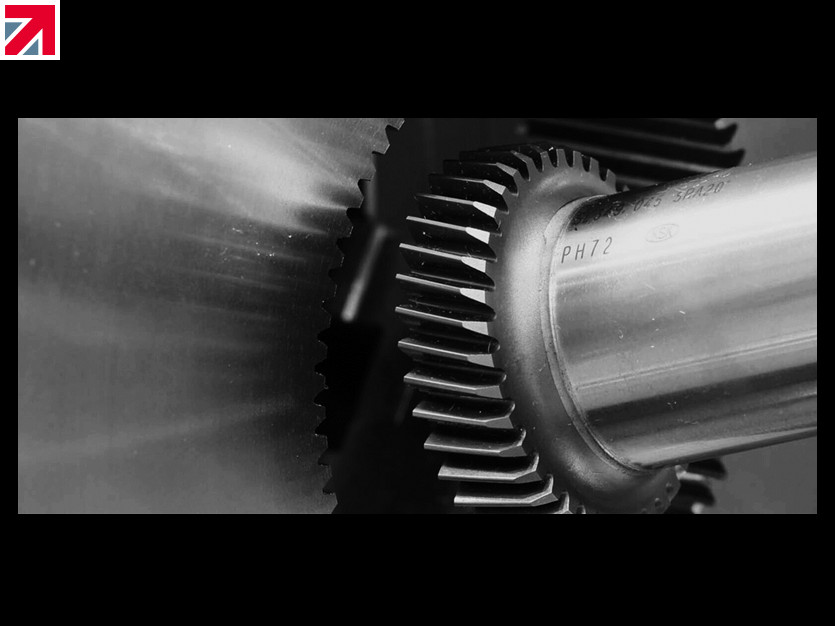

Power skiving is a more efficient and accurate alternative to milling, broaching and gear shaping, to machine both internal and external gears.

Okuma Multus U4000 Investment - Power Skiving

A leading global supplier of military aircraft electronics and longstanding customer of R E Thompson required the production of internal spur gears as part of a recent contract. In order to provide the best possible service, R E Thompson invested in power skiving capabilities with advanced Okuma machinery and tooling for gear manufacturing.

Power skiving expedites gear production due to its high cutting speeds and continuous machining sequence, allowing the turning process, rough-machining and finish-machining to be done in one clamping operation. This results in higher quality, as it prevents reclamping errors and eliminates radial deviations, significantly reducing lead times and costs for the customer, whilst ensuring higher quality standards.

Our Leitz Reference HP CMM and Hexagon QUINDOS software enable precise submicron gear inspection, enabling R E Thompson to manufacture a variety of gears to exceptional tolerances and machine a wide range of components with diverse tooling. For more information on our gear manufacturing capabilities, please visit our website for more information: https://www.rethompson.co.uk/gear-manufacturing/

Please do keep up to date by subscribing to our newsletter and follow our LinkedIn for more updates.

Find out more about R E Thompson on their member profile page here

Member-created content 3 years ago | From members