Choosing the Right Conveyor System for your Application

SPG Conveyors

There are many different types of conveyors, even different types of conveyor manufacturers to choose from. Selecting the right conveyor system for your application will positively affect your productivity and efficiency, it will also help you ergonomically in your workplace.

There are a few things to consider when choosing a conveyor system for your application, such as:

- Industry

- Product

- Handling

There are many factors that influence the design of industrial conveyors. For instance, a conveyor system for food transport will need to be constructed with high-quality, clean, food-grade materials.

An intergrated conveyor & packing table system for packing application would significantly increase efficiency and create an ergonomic environment for staff.

Knowing your industry can help you design the conveyor system that is best suited for your application.

Application examples:

+ Warehouse & Logistics

+ Vehicle Loading

+ Packing

+ Food & Drink

+ Manufacturing

+ Sortation

+ Floor to Floor

PRODUCT

When selecting a conveyor, it is important to know your product. The characteristics of the product, such as its dimensions/weight will affect the details of a conveyor when you’re in the design phase.

For instance, ask yourself the following questions:

+ Is it flammable?

+ Does it require special treatment due to conditions such as high moisture?

+ Size, shape, weight and material of product?

+ Is the product fragile?

HANDLING

The way a product is handled by employees will determine whether a powered, non-powered or combined system is suitable. If more handling of the product is required, additional details to the design of the conveyor system e.g. safety rails, conveyor motor speed, etc. and guidelines will need to be taken into account for the safety of the staff. For example, consider the space available and the availability of cleaning and maintenance staff when designing the conveyor system of a production line. These two factors can have a significant impact on the overall shape and design of the system. Thinking about these points will lead to an optimum production line design that focuses on work flow to improve productivity and efficiency.

Conveyor Types

There are numerous conveyor types and custom options available on the market today. Below are some of the most commonly purchased and utilized conveyors across various industries. Our company specializes in designing and building standard conveyor systems, as well as collaborating closely with clients to create completely bespoke conveyor system designs, tailored to their specific space and requirements.

Let's explore the two most common conveyor styles, Roller Conveyors & Belt Conveyors:

What is a Roller Conveyor?

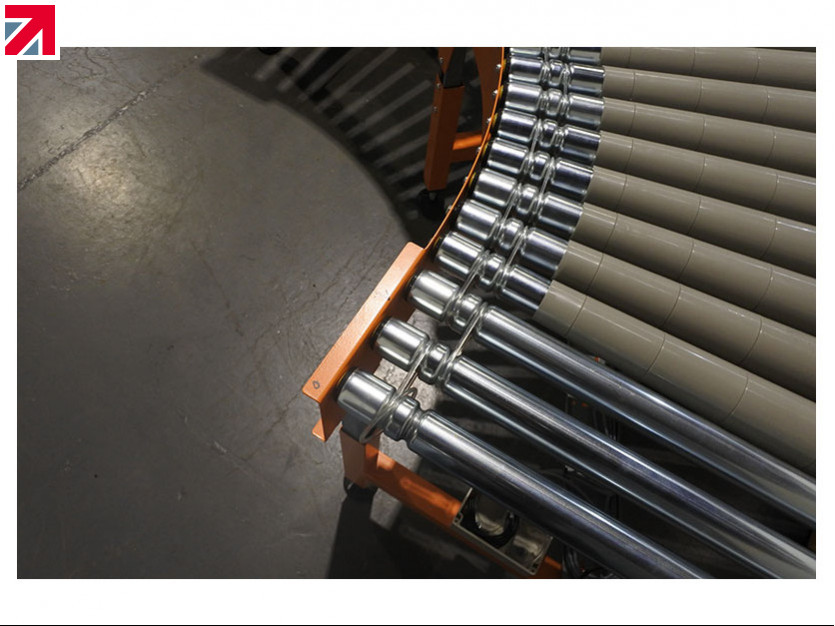

A roller conveyor is a type of conveyor system that uses a series of rollers placed in a row to transport items from one point to another. These conveyors are ideal for moving flat-bottomed items and are commonly used in various industries for efficient material handling.

Key Features of Roller Conveyors:

Construction: Made up of a continuous row of cylindrical rollers.

Movement: Items move smoothly across the rollers with minimal friction.

Ideal Items: Best for transporting flat objects like crates, boxes, totes, cartons, trays, and pallets.

Advantages of Roller Conveyors:

Efficiency: Provides a reliable method for moving products quickly and efficiently.

Versatility: Suitable for use in industrial warehouses, production factories, assembly lines, and airports.

Durability: Built to handle heavy loads and rigorous use.

Limitations:

Unsuitable Items: Not ideal for loose items like bags and packets, which can get stuck between the rollers.

Item Size: Items should be large enough to span multiple rollers for optimal movement.

Applications:

Industrial Warehouses: Streamline the handling of goods and materials.

Production Factories: Facilitate the assembly and movement of parts and products.

Assembly Lines: Enhance productivity by ensuring a smooth workflow.

Airports: Efficiently handle luggage and cargo.

By using roller conveyors, businesses can improve operational efficiency, reduce manual handling, and create a more organized workflow.

What is a Belt Conveyor?

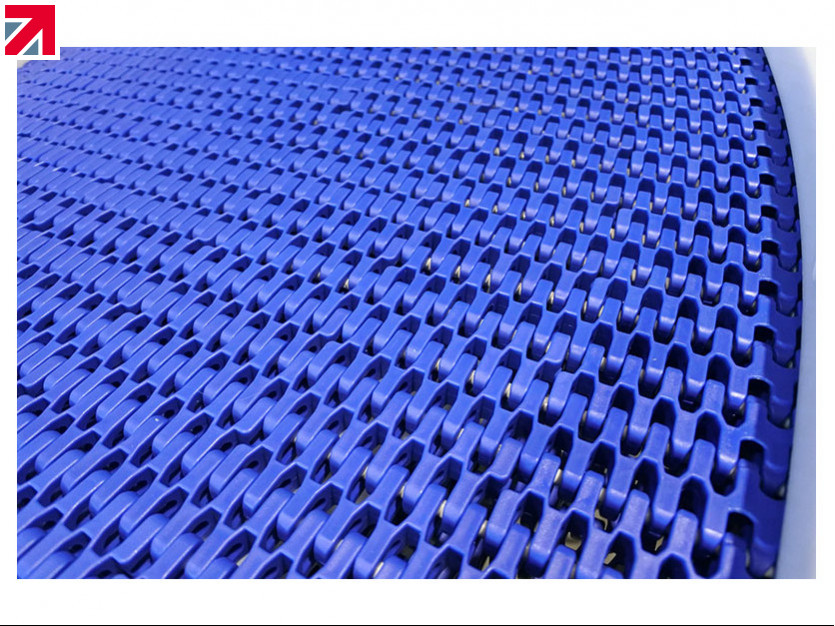

A belt conveyor is a type of conveyor system that uses a continuous belt to transport materials and products from one location to another. This versatile system is widely used across various industries due to its ability to handle a diverse range of items with efficiency and reliability.

Key Features of Belt Conveyors:

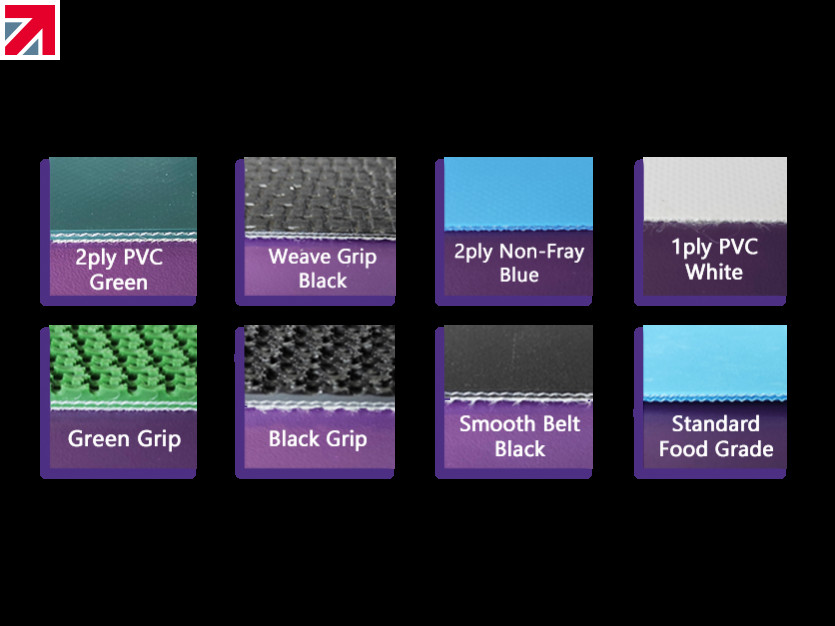

Construction: Comprised of a belt made from various materials such as rubber, fabric, or metal.

Operation: The belt moves over pulleys, providing a smooth and continuous flow for transporting items.

Ideal Items: Suitable for transporting packaged products, loose materials, packets, bagged goods, food and drink products, and luggage.

Advantages of Belt Conveyors:

Versatility: Can transport almost any item, regardless of shape or size.

Smooth Transport: Provides a flat, stable surface, ensuring items are moved efficiently.

Less Manual Handling: Reduces the need for employees to manually push items, improving workplace safety and productivity.

Limitations:

Sharp or Heavy Items: May cause damage to the belt, so these items should be handled with care or alternative conveyors should be considered.

Applications:

Farming Industries: Transporting crops and other agricultural products.

E-Fulfillment Centers: Streamlining the movement of packages and goods.

Warehouses: Facilitating efficient material handling and inventory management.

Supermarkets: Used in checkout counters and stockrooms.

Factories: Enhancing production lines and assembly processes.

Mining Industries: Moving raw materials and minerals.

By utilizing belt conveyors, businesses can achieve greater efficiency, reduce labor costs, and ensure a smooth flow of operations across various sectors.

Learn More About Different Types of Conveyors

For detailed information on the various types of conveyors available for your application, please visit our website.

Get in Touch for a FREE quote

Call: 01482 363445 Email: sales@conveyorsystems.co.uk

Find out more about Spaceguard Ltd on their member profile page here

Member-created content 1 year ago | From members