Case Study: Custom Conveyor System Integration for Maximum Efficiency

Conveyor Systems specialises in designing and manufacturing custom conveyor solutions, both standalone conveyor units and conveyors that integrate seamlessly with our clients’ existing production lines. This recent project showcases how our in-house expertise delivered a professional-grade conveyor installation that enhanced productivity without disrupting operations.

Our client approached us with a specific requirement:

- A custom belt conveyor system to work around their existing strapping machine.

- A roller conveyor that could split boxes into two rows, then feed each box individually into the strapping process.

- A pusher mechanism to divert each wrapped box down a ramp for manual handling.

- An installation schedule that would fit perfectly around their production times, preventing costly downtime.

- They needed a partner who could design, manufacture, and program the entire system in-house—without compromise on materials, performance, or deadlines.

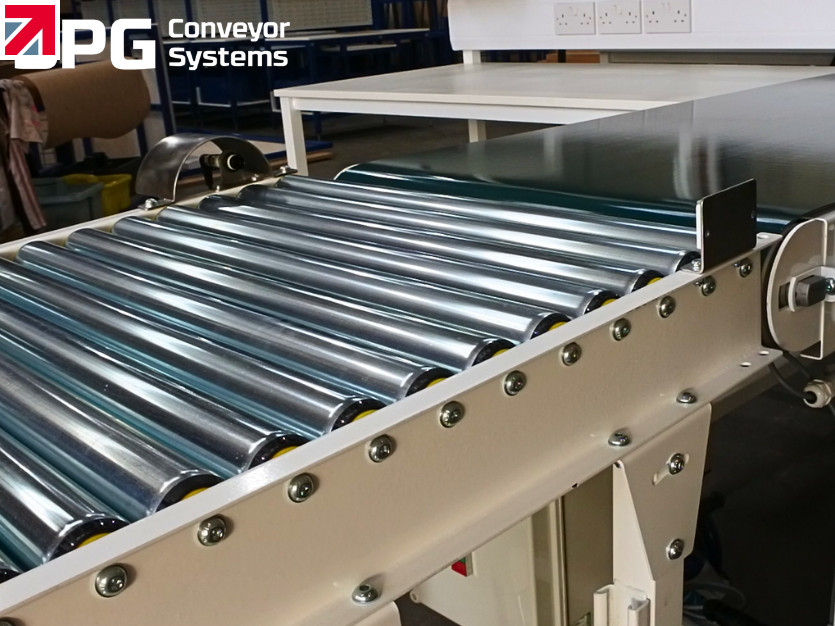

We engineered a multi-level conveyor system that combines belt conveyors, roller conveyors, and modular conveyors, configured for plug-and-play installation. Every detail—from the mechanical layout to the electrical control panel—was designed and built by our team.

Our in-house capabilities included:

Custom conveyor design to fit around existing machinery and floor space constraints.

Precision PLC programming for synchronised product flow.

Conveyor manufacturing uses robust, high-quality conveyor materials selected for durability and performance.

On-site installation, carried out around the client’s operational schedule to minimise downtime.

By designing and manufacturing everything ourselves, we eliminated the compromises that often come with third-party conveyor integrators—no limited part availability, no inflated service fees, and no delays waiting for components to arrive.

Why Choose a Conveyor Manufacturer Over an Integrator?

Many companies choose an integrator, thinking it’s the easier route. However, integrators typically order pre-made conveyor parts, which limits your design options and adds extra service charges.

When you work directly with a UK-based conveyor manufacturer like us, you benefit from:

- Full design flexibility – Every conveyor is built to your exact production needs.

- Premium materials & components – We choose the best for performance, not the cheapest in stock.

- In-house control systems – No third-party delays or compatibility issues.

- Better long-term ROI – Custom systems are designed to scale and last

The finished system now runs as an integral part of the client’s production line, splitting boxes into the required formation, feeding them into the strapping conveyor, and ensuring smooth, controlled delivery to the final handling stage. The installation improved workflow efficiency, reduced manual intervention, and allowed for future scalability.

Our ability to integrate conveyor systems with existing machinery—while installing around live production—meant the client experienced no operational disruption.

If your production line needs a bespoke conveyor system that’s truly built for you, not adapted to fit, speak to our team today about our custom conveyor manufacturing service.

Contact our Conveyor Experts | Learn More About This Integrated Custom Conveyor | View More Conveyor Case Studies

Receive a FREE quotation

Quick response guaranteed

8-5pm Mon to Thurs, and 9-3pm on Fridays

sales@conveyorsystems.co.uk 01482 363445

Find out more about Spaceguard Ltd on their member profile page here

Member-created content 1 month ago | From members