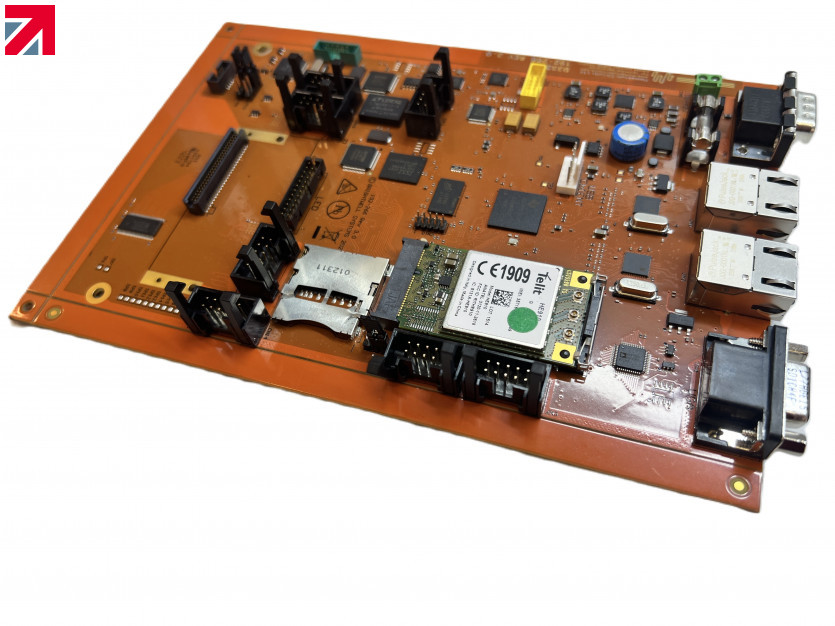

For over three decades, DSL has established itself as a reputable consultancy specializing in electronic design. We have been assisting original equipment manufacturers (OEMs) who lack the necessary internal resources or expertise in electronic design to develop the core of their industrial hardware.

During my twenty-year tenure at DSL, I have had the privilege of working closely with clients from various industries, leveraging their unique expertise while utilizing our electronic design capabilities to create cutting-edge products. Our collaboration extends beyond the design phase, as DSL often takes on the responsibility of managing the manufacturing process for the electronic solutions we develop. By carefully selecting and auditing contract electronic manufacturers (CEMs), we outsourced the PCB assembly manufacture while handling all the testing and assembly procedures in-house. This allows us to deliver anything from individual PCB assemblies to fully packaged final products, sometimes even directly to our clients' clients.

Despite our success, we have always felt that something was missing from our offerings - the ability to manufacture PCB assemblies in-house. However, for the past 33 years, the timing never seemed quite right to pursue this capability. As the Managing Director for the past five years, I understand the hesitancy, considering the numerous crises businesses have faced, from national and international challenges like Brexit and COVID to recent global supply chain disruptions that significantly impacted DSL. Electronic component shortages, in particular, have been a major issue.

It was the most recent crisis that finally prompted DSL to address this long-standing gap in our capabilities. The scarcity of components made it nearly impossible to produce PCB assemblies, and if they could be obtained, the costs were exorbitant. In some cases, extensive redesigns were required to incorporate available components. The industry was plagued with malpractices, such as large corporations hoarding specific components and component brokers taking advantage of the situation by selling them at inflated prices.

Malpractices were rampant in the industry, as major corporations monopolized the global stock of specific components and component brokers took advantage of the situation by selling low-quality parts at exorbitant prices. The electronic manufacturing industry had lost control and accountability, leaving DSL caught in the middle.

We found ourselves in a difficult position, trying to justify the significant price increases imposed by our outsourced manufacturing partners without any valid justifications ourselves. Moreover, we faced numerous manufacturing issues, including costly mistakes, especially considering the high prices of these components. Once again, DSL was left in a compromising position, disappointing our valued clients through no fault of our own. We reached a breaking point and decided that enough was enough.

In the summer of 2023, we initiated plans to bring PCB assembly in-house. The first decision we had to make was whether to utilize our existing building or establish an entirely new site. After carefully weighing the pros and cons, we concluded that the benefits of managing both the design and manufacturing processes under the same roof far outweighed any potential drawbacks.

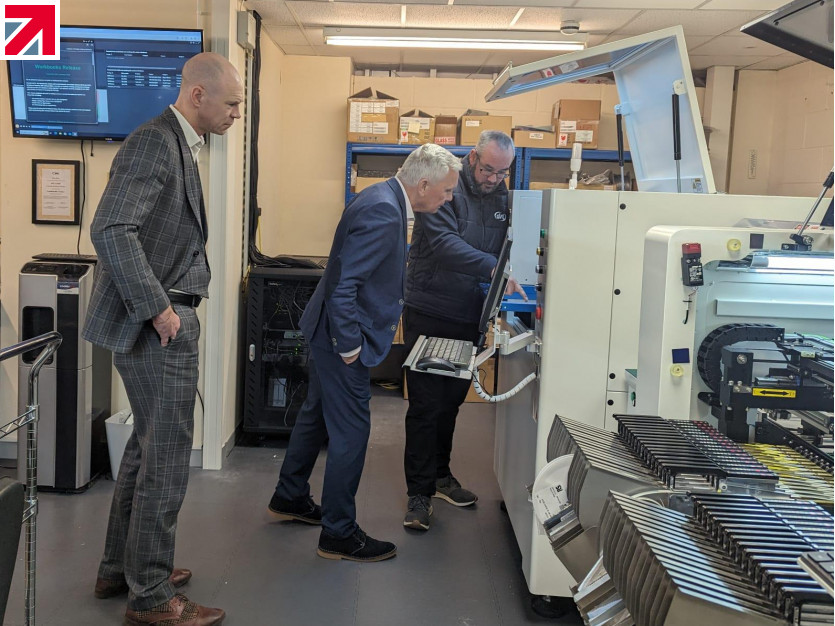

We conducted thorough research on the necessary equipment and manufacturers/models available, ultimately opting for a fully automated SMT assembly line. To enhance the inspection process, we also invested in a state-of-the-art 3D automated optical inspection machine. This device captures thousands of high-definition photos of each PCBA assembly, allowing for accurate comparisons against a known good baseline. This not only improves accuracy but also reduces the time and cost of inspection compared to relying solely on skilled human operators. Additionally, we revamped our entire production area by installing dedicated benches for through-hole assembly.

Fortunately, we already had the expertise in-house to operate this equipment. Our Production Manager had previously managed a CEM (Contract Electronics Manufacturer) in a past role, and with the support of our in-house design engineering team and the recruitment of skilled hand soldering technicians, we were well-prepared.

Therefore, by January 2024, DSL will be fully equipped to launch our manufacturing capability. This milestone not only grants us the ability to manufacture our own designs after all these years but also ensures greater control and accountability in delivering high-quality products to our clients.

Find out more about DSL - Electronic Manufacture on their member profile page here

Member-created content 1 year ago | From members