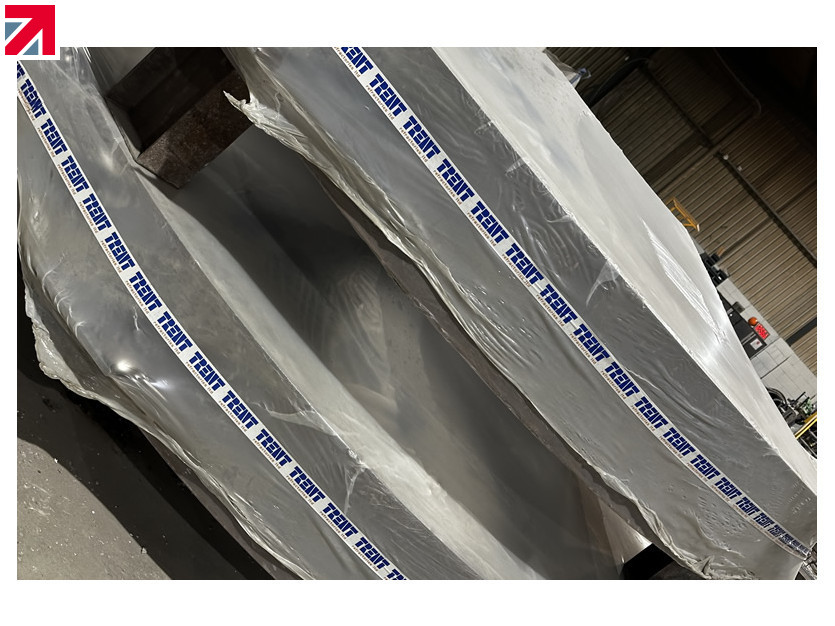

Today we celebrated a lovely dispatch to the USA for our EAF Delta Roofs which we have been successfully trialling over there for the last couple of years. Made at our factory in Scunthorpe our EAF Roof Deltas are known and highly respected in the UK market and we hold the record for roof lives at a local steel works, over 1000 heats!

Electric Arc Furnace Roofs & Deltas - Back in the early 1990’s Trent pioneered the use of a chrome based material in the refractory industry for making precast EAF Roofs and Deltas. Our precast EAF Roofs and deltas replaced older Electric Arc Furnace Roof technology where they built out of Silica, and then High Alumina bricks. It was found to be a better performer and also improved risks associated with the brick roofs cracking and falling into the furnace, which was quite a common occurrence.

Trent not only made EAF Roofs safer, but also use a unique material which is cost effective and gives greater service life. In the Electric Arc Furnace, scrap metal is melted using an electrical and chemical process. This is a very high energy process and the function of the Refractory EAF Roof or Delta is to enclose the furnace and minimise energy losses. An Electric Arc Furnace can reach temperatures in excess of 1700 degrees, with that the Electric Arc Furnace Roof is subject to exposure from various slag and metal oxides. The insulating properties of the refractory surrounding the electrodes are paramount against the thermal wear generated by the furnace.

Find out more about Trent Refractories Ltd on their member profile page here

Member-created content 2 years ago | From members