Exploring Friction Drilling: A Breakthrough for Jones Nuttall!

We're thrilled to share our journey into the world of friction drilling, marking a significant milestone for Jones Nuttall!

So, how does it work? Friction drilling is a revolutionary technique that uses heat and force to create holes without conventional drilling bits. Here's the scoop:

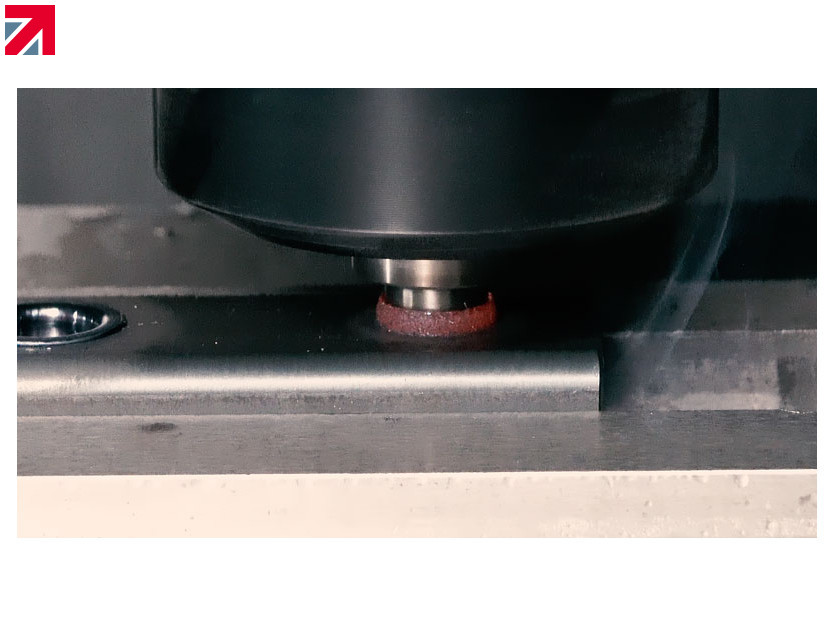

Heat & Pressure: Friction drilling applies intense heat and pressure to the workpiece's surface, softening the material and creating a plasticised layer.

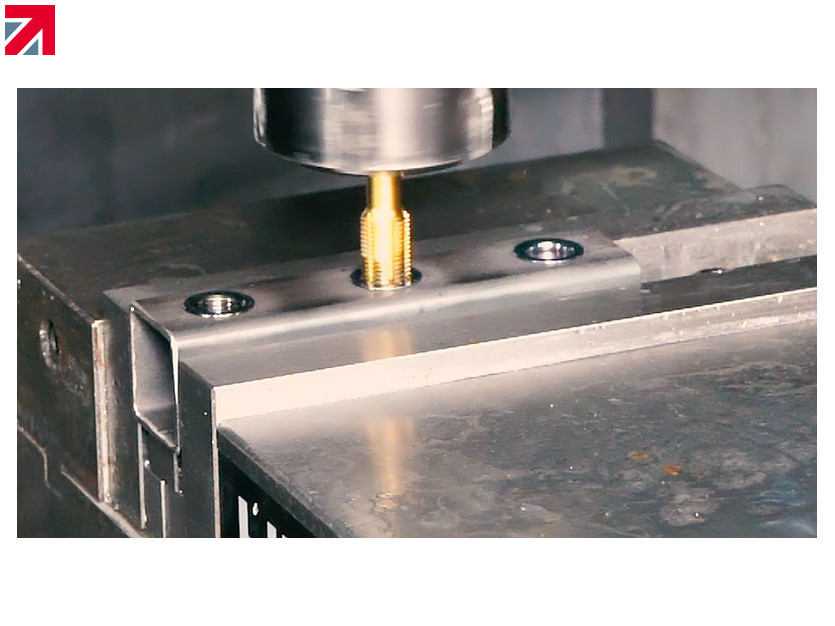

Material Displacement: As the tool penetrates the surface, the softened material displaces to form a hole, leaving behind a clean perforation that can then me thread milled.

What's groundbreaking is not just the method itself, but the remarkable speed and efficiency it offers. In our first trial run, we were astounded by the results! Friction drilling proved to be considerably faster than traditional milling with a drill bit, paving the way for enhanced productivity and reduced production times.

But wait, there's more! One of the most impressive aspects of friction drilling is its versatility. Take, for example, the thin 2mm metal section showcased in our images. Despite its delicate nature, friction drilling effortlessly creates precise holes, showcasing its remarkable capability.

We're overjoyed with the outcomes of our first foray into friction drilling and can't wait to explore further possibilities.

To find out more or get a quote please contact us on 01925 628630 or send us an email at sales@jonesnuttall.co.uk

Find out more about JONES NUTTALL LTD on their member profile page here

Member-created content 1 year ago | From members