An Overview Of Conveyor Systems

A conveyor system is fundamentally an assembly of different conveyors ( they could be the same type within different production stages , or different types of conveyors) that are assembled together to transport materials (from start to finish) with the minimum of effort compared to doing the transporting the goods manually. Conveyor systems work well in businesses where they deal with raw materials, food ingredients, through to live bird handling, heavy goods, and mass moved products such as in the food processing, Meat processing and materials handling.

Essentially a conveyor system comprises of a frame which supports the conveyor mechanism ( which could be either gravity fed or powered) . You can read more about the different types of conveyor system, how conveyor systems work, the uses of a conveyor system and how to maintain a conveyor system in a previous article ‘what is a conveyor system?‘.

How conveyor systems work – the essential components

A conveyor system has core components that are essential for it to operate just like any other technical or mechanical system. These parts of the conveyor need to be properly maintained to decrease chances that the conveyor system will no longer work properly. This of course potentially decreases risks, avoids costs, and prevents delays on production output.

How your conveyor system will be designed will depend on what the conveyor system will be carrying and the existing conveyor system . Fundamentally, all conveyor systems have the same core components for the conveyor to do its job of transporting what it’s been purchased for. Next we are going to look at these to give an insight into how conveyor systems work

Core Conveyor System Components

Driving unit

The driving unit is essentially the part that provides the motion to the conveyor for it to either go one way or another. The driving power or driving unit are the mechanical units that allow the conveyor system to run continuously and smoothly and control the direction of the conveyor system.

Pulley (Drums)

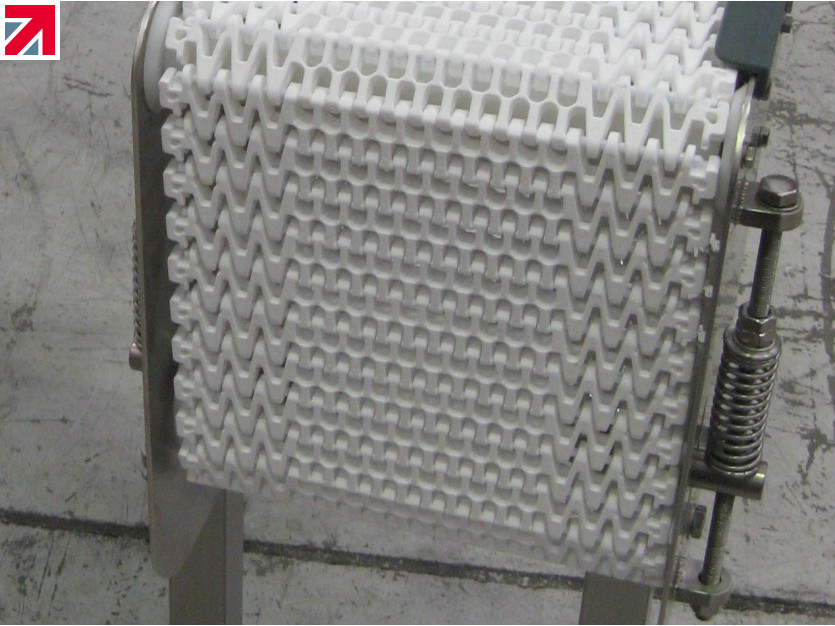

In order to operate Belt conveyor systems consist of two or more pulleys and these are sometimes referred to as drums. If you think about a rubber band wrapped around two tin cans then that provides the broadest principle. They are what the conveyor belt(s) are wrapped around to give the conveyor belt system a structure and feed the belt back around the system. As a minimum one of the pulleys will be powered that way the belt on the conveyor system will be able to move the items to the desired location. The un powered pulley is called the idler pulley while the powered pulley is called the drive pulley.

Conveyor belt support

A conveyor belt system is supported by either a flat pan or rollers along its path, that way the system has a structure to its movement and stays upright. A typical structure consists of a metal frame with rollers at each end of a flat metal bed. If it’s a heavy use application the the rollers would be more closely spaced on the system . Rubber conveyor belts are commonly used for oddly shaped or irregular shaped items to prevent the product sagging between rollers.

Conveyor Systems Specification Considerations

When installing a conveyor into your business, as part of a wider conveyor system or on its own , there are specific questions you need to consider and factor in. Evaluating the answers to these questions will help identify what sort of conveyor system you want for your business such as a shuttle conveyor, transfer conveyor, inclined belt conveyors, wire belt conveyor, slat conveyor, roller conveyor, multi lane and merge, spiral conveyor, activated roller belt, modular belt , flexible conveyors, cooling conveyors, metal detection conveyors, quick belt removal conveyors or Thermodrive for example

If you would like to discuss a bespoke designed conveyor for your business needs, the engineers at Wrightfield are and happy to discuss a solution for you.

Load capacity

This is a fundamentally important part of how any conveyor works and impacts to what conveyor system you get and what functions you have. Wrightfield as part of the design process will make sure the conveyor is built to the required length which will determine the loading capacity or the loading margins of the conveyor system.

It is important to remember that as the required load for the conveyor system increases, this will impact the width, length, and overall design of the conveyor system. The maximum load capacity of a conveyor system is based on the load capacity per unit length. Note – This is also known as flow rate.

Conveyor system speed or rated speed

- Powered roller conveyor speed is usually measured in terms of how much product, package, or volume of an item will be moving over the powered roller conveyor system.

- Belt conveyor speeds are typically rated in foot per minute (fpm)

- The speed a conveyor system works at varies depending on what’s being moved. For example if you are moving fragile and delicate fruit, that will require a different speed to robust metal cans. Controlling the speed is a key part to how conveyor systems work which can impact other factors such as throughput of the conveyor system.

Throughput

- Throughput is the measurement of the amount of product that goes through the conveyor system.

- The throughput capacity of a conveyor system is referred to as Cases Per Minute (CPM)

- Throughput is dependent on the slowest speed mainline conveyor and the length of the product that’s being transported. This is typically measured by volume per unit time such as cubic feet per minute (CFM)

- By using the two above parts will give a better determination of what the throughput of the conveyor system will be. It is important to recognise that this can be subject to change due to individual operational complexities. For example the throughput of a conveyor system that needs to be looping left and right and going up and down, will different to one that runs on a straight line

3 Things That Can Go Wrong in Conveyor Systems

With any mechanical / electrical / hydraulic/ pneumatic / electronic system there will always be things that can go wrong. As conveyor systems can incorporate all of these below we look at what we think are 3 of the common problems to watch out for.

Belt slippage

When installing a conveyor system the tension on the belts is a critical adjustment. Too little or too much tension will ultimately cause the belt to break ( which then leads to a broken conveyor system). Suitable adjustment should be available within the conveyor system to adjust the pulleys, so that correct tension can be applied to grip the belt

Listen out for screeching. Maintenance and adjustment should be performed once belt slippage occurs.

Mistracking of Conveyor Belt System

This occurs whens the conveyor belt is no longer aligned with the track the conveyor is on. If the conveyor belt drifts from one side to another when examined this is an identifiable indication of mistracking. As well as potentially causing damage to the conveyor if the conveyor is used them items can be thrown about or fall off.

As with many conveyor issues of this problem is left unresolved it has potential to impact the entire conveyor belt or even worse, the whole conveyor system. This is why it is so important to train operatives to be aware of potential issues so that they can inform maintenance land get mistracking resolved as soon as it arises. For after sales conveyor maintenance information click here

Blockages

Blockages are where the items being moved within the conveyor, are disrupted in there progress. perhaps an item has got stuck in a pinch point and as a result no further items can progress. This build-up of items on the conveyor system impacts the throughput or volume of units on the conveyor system.

Blockages are normal very noticeable and because they slow down the throughput of the conveyor system are picked up by operatives. Whilst an operative may remove a blockage ( if safe) if it is a one off , these can happen. If they happen more frequently then it could also be a sign of another problem on the conveyor system such as mistracking which would require more detailed investigation

Are you looking for a conveyor system?

If you need a conveyor system, for the food industry Wrightfield can help you identify what conveyor system specification would provide you with optimum operating effectiveness and efficiency, increasing throughput and decreasing costs, contact Wrightfield today.

For more information on conveyor systems Click Here , if you want information on Stainless Steel Conveyor Systems Click Here. Information on Food industry conveyor systems can be found here and information on conveyor manufacturers click here

For further information on stainless steel products click here

Find out more about Wrightfield Ltd on their member profile page here

Find out more about Wrightfield Ltd on their member profile page here

Member-created content 4 years ago | From members