Gopak® - Supporting the UK export economy with unique folding furniture technology.

Hundreds of our members have been with us from the very start, many of those joining Made in Britain before I did, in April, 2015 – just over eight years ago.

Gopak® are a world-leading specialist manufacturing business making lightweight folding furniture, selling across multiple UK sales channels and into Europe to the largest and, arguably, most competitive markets, France and Germany. If you’ve ever helped out volunteering at your local school, or village hall, chances are you’ve handled a Gopak® product, the iconic fold-under-leg system tables, present in thousands of public spaces, serving British communities since 1954.

Today's Gopak business is a perfect example of how an ingenious design solution has evolved and improved over decades to become an exemplary sustainable and responsible manufacturer, excelling in so many ways and proud to play such an important part in the education infrastructure of the British economy.

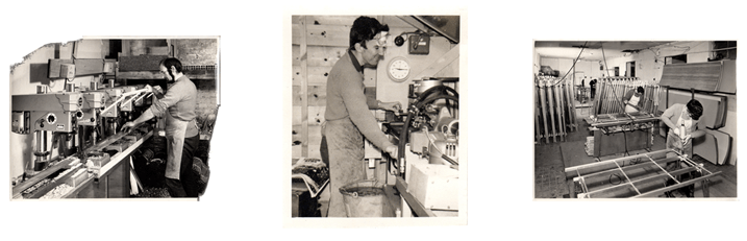

After leaving the Royal Navy, aspiring young designer and inventor, Peter Le Fleming Shepherd (1922 – 2018) founded the businesses, initially under his own name, in 1954, making innovative small pieces of furniture which were sold primarily through high-end retailers. His breakthrough came when he designed a heavy plywood folding table with a ‘pin’ leg, which he sold to schools in the south of England for their dining halls. The table was constructed using unique techniques that negated the need for screws or fixing - these principles continue to be used in the basic construction of the thousands of tables, benches and other furniture Gopak makes today at their plant in Hythe, Kent. One of the earliest scaled demonstration models is proudly on display at the factory along with other reminders of the effortless and brilliant design.

I spoke to Sales & Marketing Director, Diane Ponting about the unique, omnipresent nature of the products Gopak manufacture, and how the many, interlocking business challenges of recent years appear to have strengthened the company’s resolve to grow and expand their cherished export markets.

“We do all genuinely love the product design which essentially remains aesthetically unchanged from the original design. Our customers and end-users will tell us it lasts ‘forever’, it’s lightweight, affordable, wipe-clean, safe and easy to store and even easier to set up. Some design concepts are almost perfect on inception and our work here at Gopak today is to keep improving and innovating to offer more great British products with this incredible design heritage in their DNA. We are all really proud to be taking responsibility for Peter Shepherd’s remarkable design legacy. We aim to make it even more appealing with each new innovation.”

Sales & Marketing Director, Diane Ponting

Gopak, like so many British exporters, have had to navigate their way through some very difficult economic challenges and geo-political changes, on top of coping with the Covid pandemic in 2020. The UK leaving the European Union has certainly not been easy for exporters in all sectors, but Gopak have managed to maintain their market presence in both Germany and France, two of the EU’s largest and most competitive markets. Diane expands on how Gopak have focused on environmental concerns to appeal to the new, green demands for their customers;

“We take all our social and environmental responsibilities seriously and publish both our objectives and actions to bring about a cleaner, greener business. All our customers, at home and abroad are asking ever deeper questions of business communities as to whether they have policies on sustainability and are taking measurable actions based on them. Gopak go further and faster every year, recycling waste materials wherever possible and holding a "Zero to Landfill" policy. We review all our packaging to reduce transit damage and minimise the consumption of materials and make accurate recording and analysis of the reasons for waste, to make better decisions about how to eliminate it. We’ve installed an additional 250 solar panels to increase the generation of our own cleaner energy and work to reduce overall energy consumption in the plant with efficiency measures. Our move to be a more circular business means we review all our raw materials and investigate the availability of environmentally friendly alternatives, wherever viable.”

Andrew Fieldwick, Managing Director

|

|

|

In line with Made in Britain, code of conduct, Gopak are always looking for new UK suppliers and partnerships that will give them even tighter control over quality and supply. It’s also a great way to support local industries and reduce product carbon footprints.

Like pottery connoisseurs turning over a plate to see where it was made, Gopak enthusiasts (and I count myself to be in that group) can glance at the underside of any item of their furniture to get the trust and reassurance the product was made in Hythe, Kent, close to where it is being used in the UK - in my case, at the local Cub Scout Hall in Cambridge where I was helping out setting up the tables and chairs. Some simply perfect designs get a little bit better with every new generation.

All of this is what being a successful British manufacturing enterprise looks like in 2023 and what should give us all confidence for the future of our sector.

By Made in Britain 2 years ago | By Made in Britain