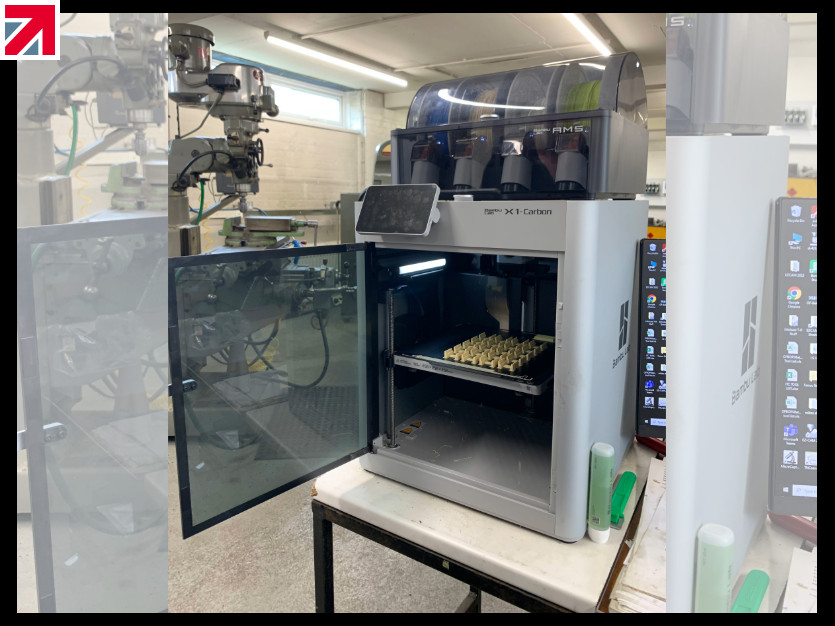

OF Bell has recently invested in quality 3D printing technology, supporting our in-house tooling workshop in Bishop Auckland, Co. Durham, with the latest kit which efficiently and accurately reproduces small production-run components and prototypes as part of our product design and development work.

Now in situ, and following a period of testing and trialling, our new printer is generating returns for the tooling team, producing miniature parts and prototypes with pin-point accuracy at the touch of a button.

Leading 3D print technology to support OF Bell's miniature component engineering

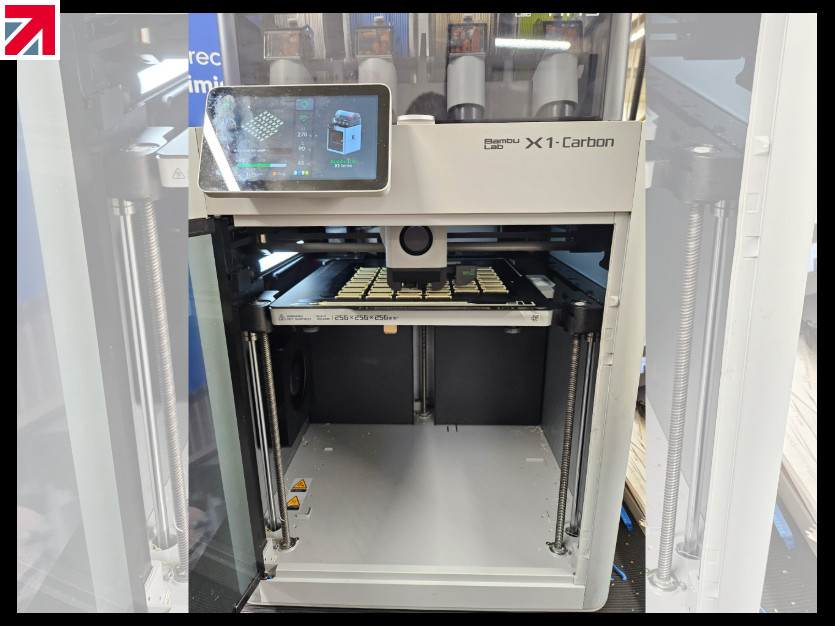

Our new printer is equipped with multi-colour and multi-material capabilities, working with up to 16 different colours and producing high-quality print at 7 μm LiDAR resolution to showcase the Bambu Lab X1-Carbon model's technical innovation and excellent versatility.

Utilising a range of materials, including Polyamide (PA), Polycarbonates (PC), Polyethylene Terephthalate (PET) and Thermoplastic Polyurethane (TPU), our model specialises in particular in handling carbon fibre and glass fibre-reinforced polymers. This range of applications gives our tooling workshop a great range of options to work with, selecting materials based on our clients' products and the demands of each component's application in the field.

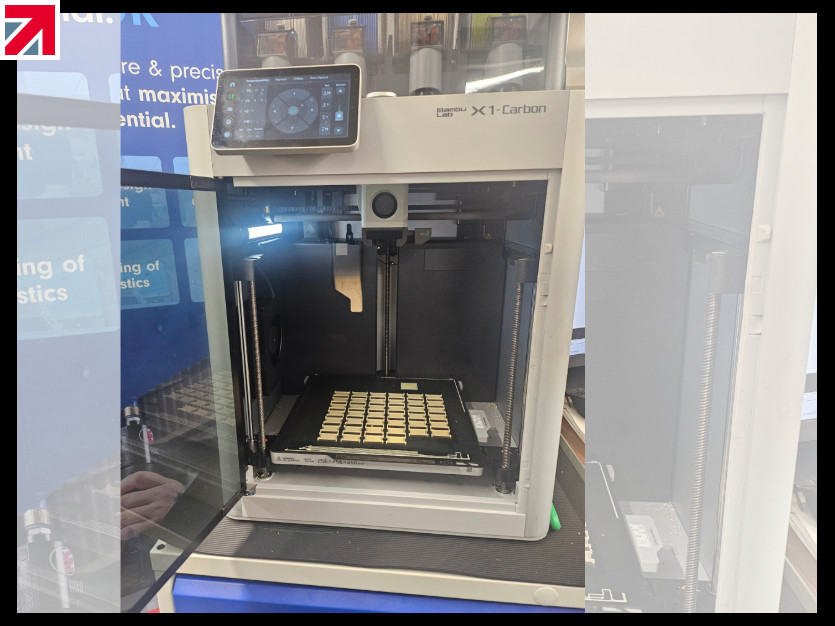

So why choose 3D printing? OF Bell is a miniature component specialist, and we're equipped with industry-leading injection moulding technology which produces reliable and consistent plastics. However, some production runs are low and product prototypes are under continual development in their early design stages.

3D printing allows us to create and fine-tune miniature parts and components without the need for a specialist moulding tool, generated using 3D CAD software. Clients will benefit from cost and time efficiencies, while every component is subject to the strict quality control checks implemented across OF Bell's work.

OF Bell's Managing Director Mark Beard comments:

"We have always been injection moulders and we are unique to have our own in-house toolroom. Tooling remains the most cost-effective option for our customers manufacturing high-volume miniature parts and components, but there are occasions where it is more efficient for a small production run to be 3D printed.

By acquiring our own equipment and using it in-house as part of our tooling and early production processes, OF Bell retains its commitment to complete confidentiality throughout the product development process whilst delivering components and miniature plastics efficiently and cost-effectively to meet our clients' lead times. Quality monitoring is essential, maintaining consistency and accuracy across our production whether through injection moulding or 3D print to deliver reliable components that perform as they should."

UK-manufactured complex miniature components by OF Bell

Since 1973, OF Bell has worked alongside clients in many sectors, from those in oil, gas and utilities to medical, construction, consumer goods and household products, as a trusted manufacturing partner based wholly in the UK to deliver fully-assembled, tested and quality-assured complex components and moulded parts that form a vital part of supply chains across the UK and worldwide.

ISO-certified, and with over 50 years' experience, from confidential in-house product design and development to injection moulding, assembly and testing of electrical and precision parts, miniature and complex small parts by OF Bell enable client businesses to achieve their full potential through reliable, confidential and complete complex component engineering.

Find out more about complex component manufacturing & engineering with OF Bell

OF Bell's miniature component engineering team in Bishop Auckland, County Durham, delivers reliable, consistent and highly-accurate electrical assemblies and moulded small parts for cross-sector organisations in the North East. Get in touch to find out more about our manufacturing processes and book a meeting with our team.

Find out more about OF Bell on their member profile page here

Member-created content 11 months ago | From members