Over the past 35 years, the composition of carbon components has undergone significant changes. Advances in binders, fillers, and impregnation agents have dramatically impacted the way these materials respond during the polishing process. Historically, impregnating carbon to reduce its porosity was a common practise, but modern assemblies now demand more complex carbon composites. As a result, materials like antimony, copper, and other additives are increasingly used in the manufacturing process.

These new combinations of materials present unique challenges when striving for a flawless mirror polish. As a leading supplier to the carbon finishing industry, Kemet International has dedicated extensive research to understanding and overcoming these challenges.

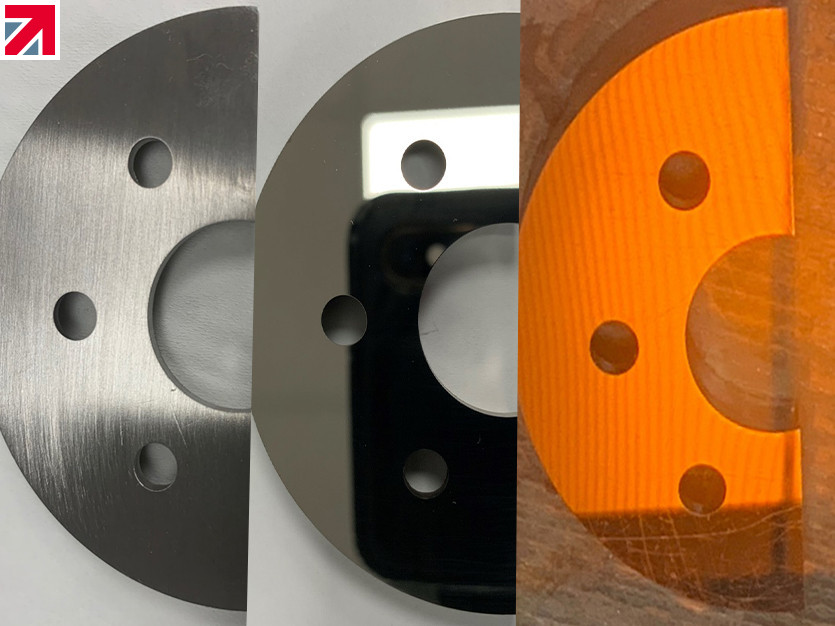

Kemet offers a range of highly effective polishing solutions for all types of carbon composites. One of the most straightforward methods is their special Diamond Slurry, which is applied to cast-iron lapping plates. This process is ideal for smaller, low-volume components but requires the careful preparation of the cast-iron plate. It functions as a burnishing process, utilising a minimal amount of slurry to achieve a polished surface. The correct formulation of the slurry is crucial for success—if it is too wet or too dry, the carbon will not polish. Kemet has specifically designed its slurry to meet the unique requirements of this process.

For a more streamlined and repeatable solution, Kemet offers its Kemet Copper SP2 material, used in conjunction with either 3 or 6 micron diamond slurry. The size of the machine and the weight of the components determine which diamond slurry is optimal. This process is easier to maintain as it eliminates the need for pre-preparing the lapping plate. Additionally, it can handle multiple parts in a single run, providing consistent, high-quality surface finishing results. The Kemet composite material, being softer and resin-based, allows diamond particles to embed into the Kemet material, preventing them from embedding in the carbon itself—a critical factor for maintaining the integrity of the carbon surface.

Kemet has also developed a portable lapping kit specifically for carbon seals. This kit features a lapped aluminium substrate and five superfine abrasive discs, allowing for the precise lapping of seals without the need for loose abrasives. This innovation provides an efficient and portable solution for on-the-go applications.

Kemet offers free process development and component trials to assist you in achieving the perfect polish for your carbon or carbon composite materials. For more information, or to discuss your specific needs, please contact us at: Tel: +44 (0) 1622 755287 or sales@kemet.co.uk

Whether you are dealing with simple carbon composites or advanced, complex materials, Kemet has the expertise and solutions to deliver unparallelled mirror polishing results.

Find out more about Kemet International Ltd on their member profile page here

Member-created content 1 year ago | From members