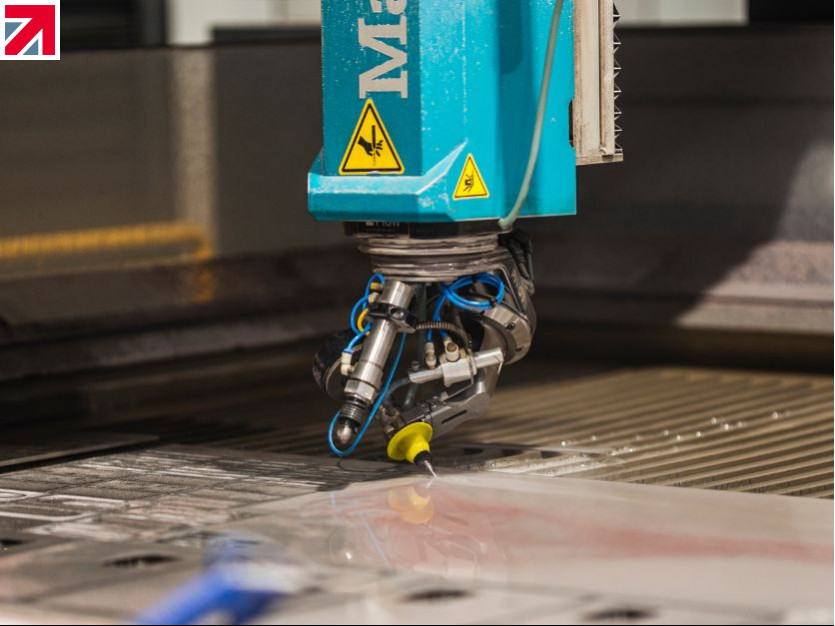

Last year, here at Instinct Hardware, we took the plunge and made a large investment in a brand-new waterjet cutting machine. This is proven its worth many times over when it comes to intricate cuts and thick sheet metal. But what are the advantages to using this machine over its laser cutting counterparts? Here we look at laser v waterjet and where each would be most useful, through analysing areas like precision, environmental impact and speed.

Precision and Accuracy

Laser – The word LASER stands for Light Amplification by Stimulated Emission of Radiation. This is because the technology uses a focussed beam of light to cut materials at a high precision level. This technology lends itself to tight tolerances, which can be as fine as 0.1mm. Due to this precise nature, laser cutting has a small heat-affected zone (HAZ) – meaning minimal warping or distortion. Laser has therefore long been a top choice for items needing intricate cuts and clean edges.

Waterjet – The waterjet delivers its cuts by using a highly pressurized water stream. Our waterjet mixes this with a fine garnet abrasive, which turns into a slurry that cuts through materials. Similarly to the laser, the waterjet offers tolerance levels of around 0.1mm, but with particular advanced set-ups, can be even tighter. There is no heat used in this process, eliminating the HAZ zone and making this ideal for cutting heat-sensitive materials.

Winner: Waterjet, thanks to its lack of heat being used in the process, removing any distortion.

Material Versatility

Laser – The laser works best with items that absorb light well, like metals, plastic, wood and some ceramics. However, it can struggle with reflective materials such as copper and aluminium without the addition of specialised equipment. Laser can currently effectively deal with materials up to around 20mm thick, although this is increasing constantly as technology advances.

Waterjet – This is where the waterjet really comes into its own, effortlessly slicing through virtually any material. This machine can handle most raw material, from metals and plastic through to glass, stone and any composites. This machine can easily deal with material up to 300mm thick. This means it’s a good choice for heavy-duty work.

Winner: Waterjet, thanks to its ability to work with all materials and offer cutting to a thicker depth.

Environmental Impact

Laser – Laser cutting doesn’t have a huge impact on the environment waste-wise, as it often produces minimal scrappage. However, this way of cutting does require a significant amount of electricity – especially when this is a high-powered laser. Laser cutting can generate hazardous fumes depending on the item being cut. This can mean that operators need correct PPE and that buildings need the right ventilation and filtration systems.

Waterjet – The waterjet is considered to be quite environmentally friendly, as the materials that are used are natural. The waterjet doesn’t use heat, reducing the need for extra systems. Using a waterjet does mean that wastewater is produced, but this can generally be treated and recycled. The garnet abrasive is also non-toxic and can be disposed of or recycled responsibly.

Winner: Waterjet, as this uses natural materials to cut through items.

Operational Costs

Laser – The initial investment for laser equipment can be high. Costs can vary depending on the type of laser, the power needed and the overall capabilities. More regular costs include electricity, maintenance and consumables like the gases used in the cutting process. However, these costs are often offset by the high-speed, high-volume runs that are the heart of laser cutting.

Waterjet – Again, initial investment for this type of cutting machinery is high, requiring high-pressure pumps and advanced abrasive systems. The operational costs include water, abrasives, electricity and maintenance. This can mean a higher cost-per-unit (CPU). The waterjet comes into its own when handling a wide range of materials, potentially offering offer cost savings in multi-material projects.

Winner: Laser. Dealing with high-speed volume orders often brings down the CPU.

Speed and Efficiency

Laser – Using a laser to cut materials is usually faster than waterjet cutting, especially when it comes to medium thickness items. The laser’s high speed and precise automation mean it is ideal for mass production. However, as the thickness of the material increases, the speed decreases – and with much thicker materials you may find that edge quality is compromised.

Waterjet – Slow but steady is the waterjet’s mantra. When using thin materials, there is no comparison between the two. However, when the thickness increases, the waterjet is unfazed, carrying out its work at the same pace and with an unmatched edge consistency. The speed of the waterjet can be adjusted to suit the material in hand and to provide the desired finish – meaning more flexibility on costs.

Winner: Laser: Under 20mm. Waterjet: Over 20mm.

So…who wins in laser v waterjet? Waterjet and laser cutting offer different advantages to the end user. The right cutting method largely depends on the job in hand. Laser is a fantastic choice for slimmer materials, thanks to its speed, precision and cost-effectiveness. When high-volume product is being created, the laser really comes into its own. Waterjet cutting is more methodical, but allows you to have unparallelled versatility with its ability to handle a broad range of materials and cut thicker items. When cutting heat-sensitive or reflective materials the waterjet also offers no thermal distortion.

If you are considering whether a waterjet might be right for your project, please contact Instinct Hardware, we’ll be more than happy to advise you. Our waterjet is a new Flow Waterjet Mach 200, with a large 4m x 2m bed size.

Find out more about Instinct Hardware on their member profile page here

Member-created content 1 year ago | From members