ABSORBENT paper manufacturer ICT Poland was inaugurated in 2001, in Kostrzyn. Today the facility is the most technologically advanced European site in the industry and is one of the most important production sites in Europe. It has reached a production capacity of 210,000 tonnes with three continuous machines.

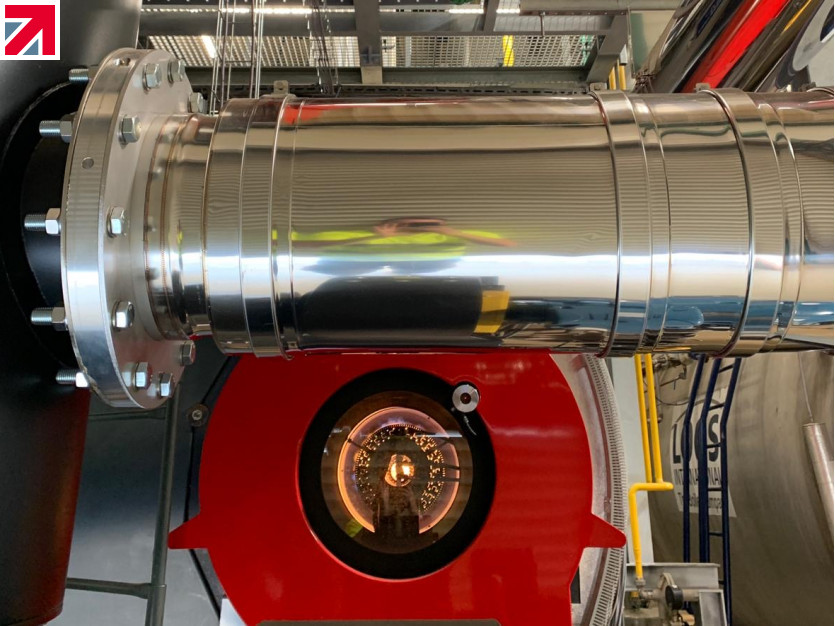

Limpsfield has upgraded their boiler which already has 25 years of history. With our new generation pre-heated burner with FGR we have been able to increase the boiler efficiency and reduce the NOx emission. This type of design can take the inlet temperature up to 100degC and increase the combustion efficiency. Furthermore, the NOx can also achieve within 80mg/nm3.

With Limpsfield burners, which can fire gas, oil, hydrogen or bioethanol, the boiler system can be modernized. This project uses waste heat to heat the combustion air and has already achieved 6-12% in fuel savings.

Find out more about Limpsfield Combustion Engineering Co Ltd on their member profile page here

Member-created content 3 years ago | From members