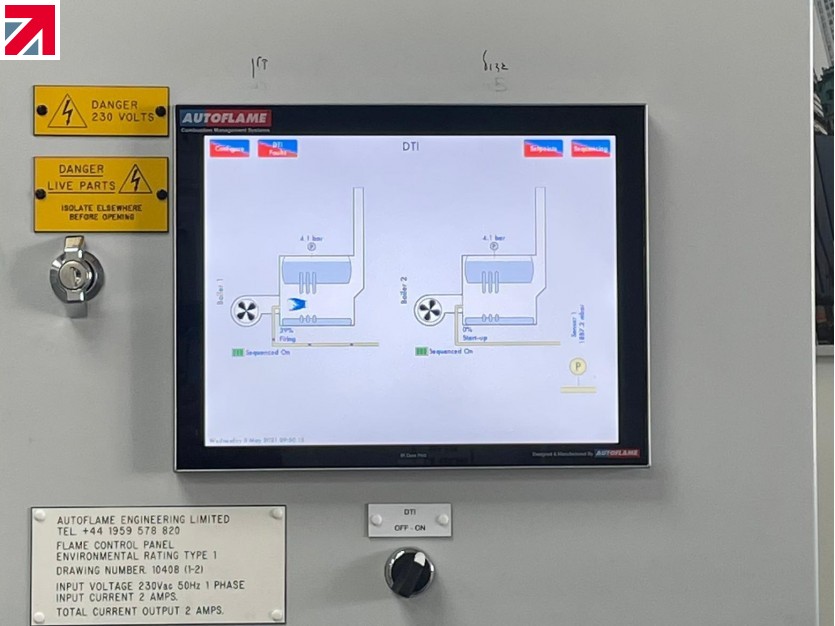

On this site our technology centre have upgraded the burners on 2 x 20+ years old 4 T/hr steam boilers. The existing burners could only fire the boiler at max. 3 T/hr steam output, so both boilers had to be on-line to meet the steam demand. Operation was done normally with one leading boiler and with a manual change over.

The old burners were running on heavy fuel oil, however it was quite difficult with a lot of operating issues, inefficient running, dark smoke exhaust from time to time and unexpected shut downs due to bad flame stability. These issues and environmental reasons prompted the client to move to natural gas fuel and replace the burners to solve the multiple problems they were experiencing not just with combustion, high running costs, but also on the control/remote monitoring aspect.

Project Results:

a. Using our superior flame characteristics within the burner meant the full boiler steam output could be achieved, it is 25% more compared to the old burner.

b. Full load achieved by using 1 boiler only as apposed to 2. Boiler Number 2 is now only used as a backup.

c. Fuel consumption BTU (heat input) / T/hr of steam has reduced by almost 20% - huge fuel savings achieved.

i. Substantial O2/excess air reduction and increased turndown ratio.

ii. Set point control to 0.1 bar/1psi accuracy.

d. System has been running 6 months with no faults at all!!

The client is extremely satisfied with the products and the installation and services that MELKAM provided and now allows for other potential new clients to also look at the site as a great reference install.

Find out more about Limpsfield Combustion Engineering Co Ltd on their member profile page here

Member-created content 4 years ago | From members