Our client

Pipeline integrity inspection and fault detection technologies are continually evolving, testing oil and gas pipelines and their associated infrastructure internally and externally, onshore and offshore, for faults, tampering and other damage which may lead to loss of these essential, and valuable, utilities.

Wound coils manufactured by OF Bell are complex, miniature and highly reliable, integrated into our client’s production lines for the manufacture of larger sensor assemblies and state-of-the-art technologies, including MFL sensors and equipment, that protect and secure power supplies to millions of people worldwide.

Miniature coil winding & component engineering

A long-established, close working relationship with our client has developed a deep understanding amongst our team of this leading manufacturer’s sensor and fault detection technologies, developed in the UK and worldwide for the oil and gas industry.

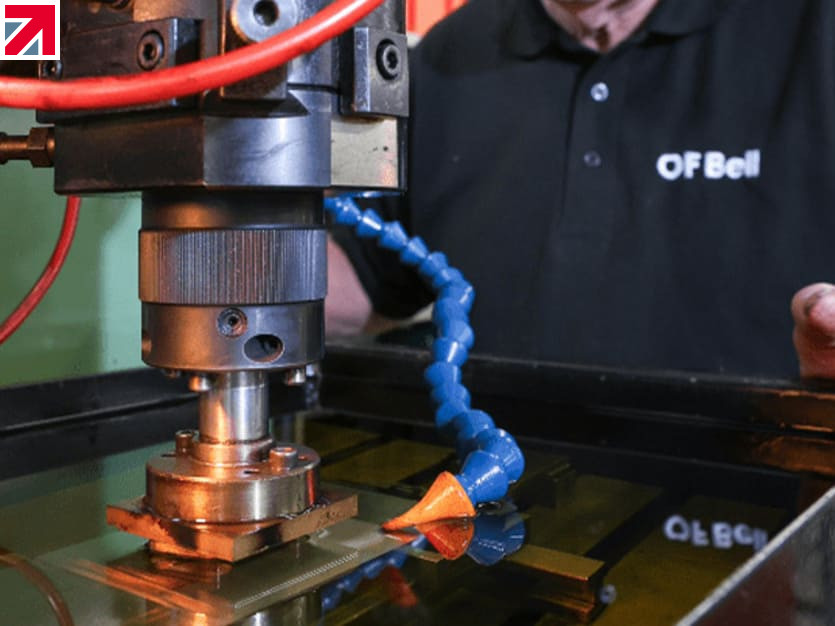

OF Bell’s UK-based complex electrical component specialists consult regularly with our client’s engineers, developing miniature, precision wound coil components during our Product Design & Development phase that are consistently reliable and capable of scalable production, or production in low quantities as required, by our skilled in-house engineering team without compromise on quality.

Wound coil components for the oil & gas sector

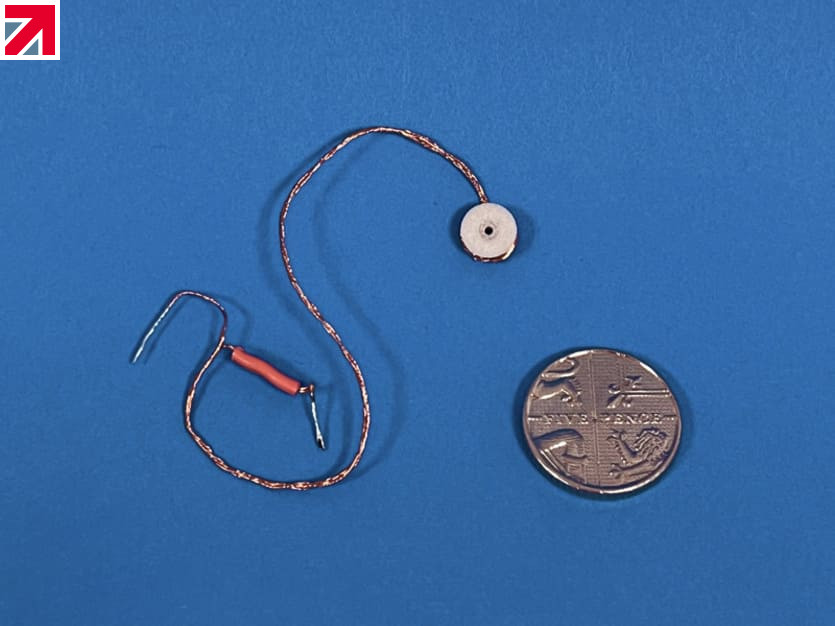

This wound coil, produced by OF Bell using a fine 0.08mm copper wire, is incorporated by our client into the manufacture of much larger sensor assemblies for the inspection and testing of tension wires used by the oil and gas sector to support utilities pipelines.

An example of magnetic flux technology, sensors monitor the integrity and tension of wires which prevent pipelines collapsing as they come onshore, ensuring the continued supply of these essential utilities to millions of people.

In-house production of miniature wound coils

OF Bell’s product design for this miniature wound coil, developed entirely in-house, features a 6.5mm 3D-printed bobbin onto which the copper wire is wound several hundred times. This allows our client to order smaller quantities as needed, dispatching quickly for a prompt arrival into our client’s production lines whilst enabling it to control costs, reduce lead times and avoid wastage.

Prior to dispatch of every wound coil, OF Bell’s electrical assembly team tests each coil for resistance and voltage, supplying testing information with every component for unmatched quality assurance and performance in the field that our client can rely on.

Reliable UK-based miniature coil winding

Our client sought a UK-based manufacturer for its miniature wound coil components, enabling it to establish a trusted working relationship that continually develops wound coils and other complex miniature components for use in essential oil, gas and subsea technologies.

Our team comprises MFL sensor specialists and experienced electrical engineers, efficiently and expertly manufacturing cost-effective wound coil components that are fully-tested and delivered quickly, ready for assembly and use to support uninterrupted energy production worldwide.

Precision component manufacturing since 1973

Since 1973, OF Bell has worked alongside clients in countless sectors, from oil, gas and utilities to medical, construction, consumer goods and household products, as a trusted injection moulding and manufacturing partner based wholly in the UK to deliver quality-assured complex miniature plastic components and moulded plastics that form a vital part of supply chains across the UK and worldwide.

Find out more about OF Bell on their member profile page here

Member-created content 1 month ago | From members