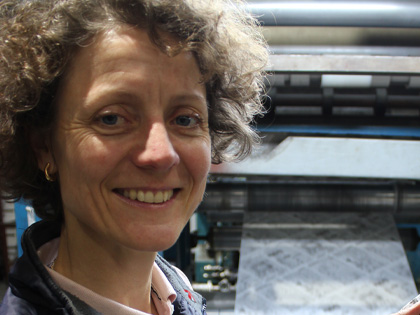

ROACH Bridge Tissues makes the fine wrapping material that is used to protect and present luxury products. It does this from its historic mill base near Preston. The company has recently joined the Green Growth Programme and director Camilla Hadcock (left) describes the experience.

ROACH Bridge Tissues makes the fine wrapping material that is used to protect and present luxury products. It does this from its historic mill base near Preston. The company has recently joined the Green Growth Programme and director Camilla Hadcock (left) describes the experience.

How integral do you see sustainable business practices to the future of your business?

We have been working on increasing the use of sustainable business practices for the last 12 years, challenging the mindset that things can’t be changed because ‘that’s how we have always done it’.

It is imperative that we understand and minimise the environmental impact of what we do. If we don’t improve sustainability there won’t be a future.

To what extent does your approach to sustainable business set you apart (in your sector)?

Our aim has been for long-term, organic growth by always producing the best quality in the best way we can.

We don’t cut corners, or prices, to try to compete. Sustainability is about all our tomorrows and not the quick fix for today.

What are the advantages of doing business sustainably?

A good night's sleep, no nasty surprises when the government makes announcements, and being able to say ‘yes’ when customers ask sustainability questions.

How have you engaged your team members/supply chain/other stakeholders around the Green Growth Programme, if at all?

Not yet, the team are already engaged and we are not very target driven.

What advice would you give to Made in Britain members as they progress on their sustainability journeys?

Don’t rush, small steps, you can’t change everything all at once. Look at the long term, how the sustainability steps you are making today will secure a better future for the business. Make sure the whole team is on board. Try to make it a life choice, not a tick box experience.

If you would like your business to join the Green Growth Programme, the journey starts here: https://green.madeinbritain.org/

For more information about Roach Bridge Tissues, see the company’s member profile page here.

By Made in Britain 3 years ago | By Made in Britain