Hanson Bulls Lodge is based in Chelmsford, Essex. The quarry site is located on a former airfield and first took up operations in 1990. Bulls Lodge now supplies over 750,000 tonnes of sand and gravel to the South East region. The site’s main operation is concrete production however they also undertake asphalt, bagging and third-party recycling activities. The current processing plant at Bulls Lodge has a capacity of 425 tonnes per hour.

Wet Processing Screens

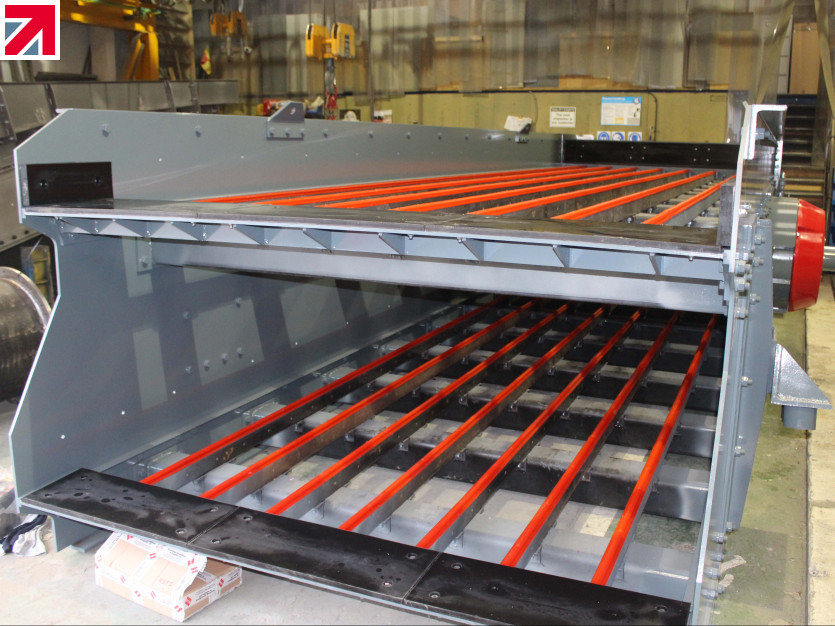

The decision was taken earlier in the year to replace the two main grading screens at Hanson Bulls Lodge, the job was awarded to Hewitt Robins. The job entailed replacing screen one - a 2.4m x 7.2m double deck machine, and screen two - a 2.4m x 6.0m double deck machine.

Both are wet processing screens with screen one separating the 10mm product on the top deck and coarse sand product on the bottom deck, screen two separates the 40mm product on the top deck and 20mm product on the bottom deck.

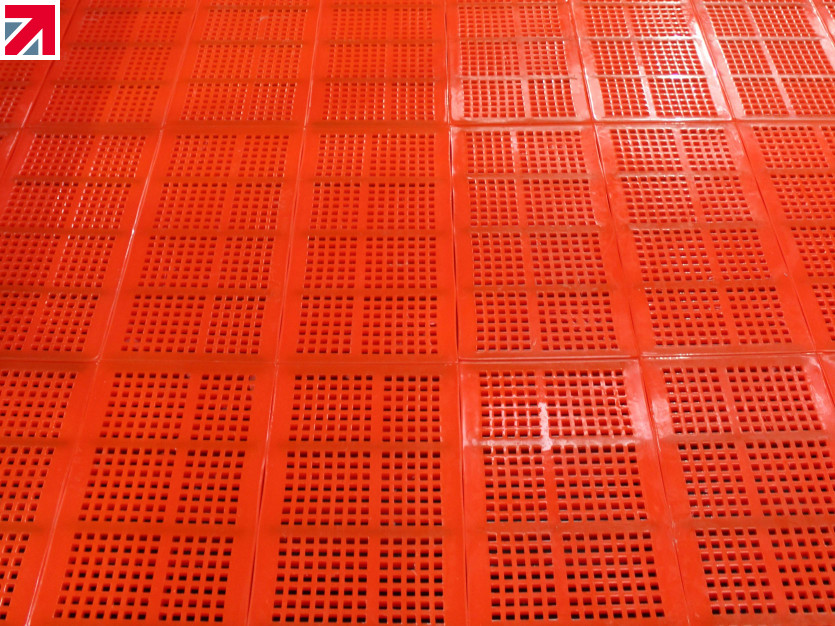

Polyurethane Modular Systems

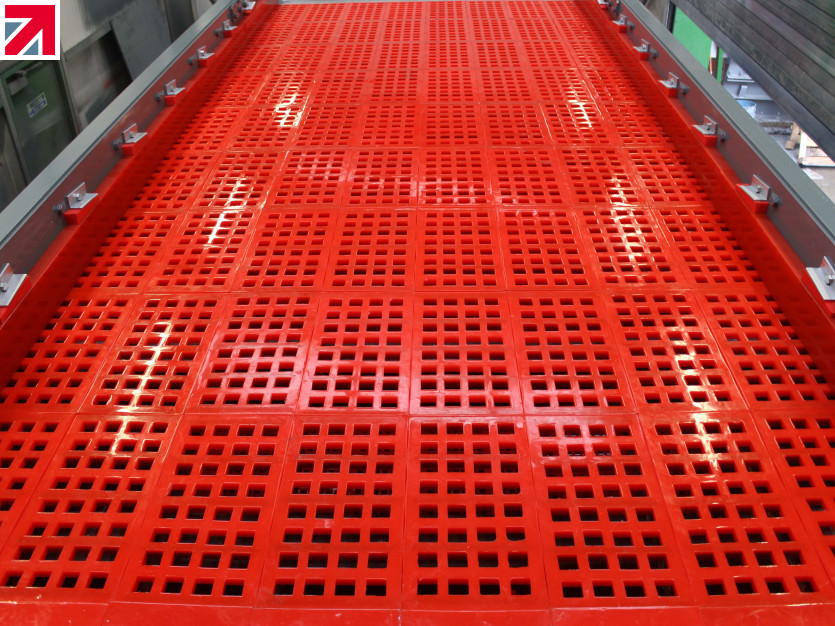

Screening Consultancy and Supplies (SCS) were chosen to supply and install polyurethane modular systems to suit the two Hewitt Robins double deck screens. One of the most popular polyurethane systems in the industry was specified – the 85 System.

SCS’s scope of supply included the polyurethane modules, side retention bars, polyurethane side wedges, cleats, knockin bars and 85 support girders. The specially designed 85 system support girder was cut and drilled to suit both screens. The girder is stocked in different sizes and lengths at SCS’s facility in Rugby.

SCS prides itself on efficiency within the industry - the installation of the modular systems for Bulls Lodge were completed at Hewitt Robins works in just one day.

Excellence in Manufacturing Synthetic Screen Media

SCS’s expertise in the design and manufacture of synthetic screen media places them as one of the leading suppliers within the quarrying industry. The fact that SCS’s polyurethane products are also designed and manufactured within the UK gives them a distinct advantage in the supply chain process.

When specifying a polyurethane modular system, several factors are taken into consideration including application, screen design, aperture shape and size. SCS have the capability to design modular systems to suit multiple types of screens with different grading applications.

Modules are one of the many products that SCS specialises in along with rubber screen media, wear resistant liners, scrapers and various other screen accessories. SCS also supply key ancillary products to the quarrying and recycling industries with exceptional delivery times.

A Bespoke Solution

If you are looking for technical advice, a tailor-made solution for your screening or lining requirements, or further information, contact us today - sales@scsrugby.co.uk or on 01788 553300.

Find out more about Screening Consultancy and Supplies Ltd on their member profile page here

Member-created content 2 years ago | From members