Forterra is a leading manufacturer of a diverse range of clay and concrete building products, used extensively within the construction sector. It is the second largest brick and aircrete block manufacturer in the country, and the only producer of the iconic London Brick. Below, Forterra tells us more.

What do you manufacture and where do you do that?

From our manufacturing sites across the country, our 1800 employees create the bricks, blocks, precast concrete, paving and many other vital products and services that are Keeping Britain Building, enabling the development of thriving communities and infrastructure.

How long has your business been going and is there any interesting history?

Forterra has a rich history and our portfolio contains some of the most recognised and respected names in the construction industry. Some of them, such as London Brick and Butterley, date back to the 19th century while others, such as Ecostock and Thermalite, are far more recent; but whether historic or modern, traditional or cutting edge, they all have the needs of the 21st century at their core.

Originally founded in the 1960’s as Hanson’s UK building products division and following a number of acquisitions, the Forterra brand was born. In 2016, Forterra gained admission to the London Stock Exchange as an independent listed company, a key milestone in our history.

What does it mean to you to be a part of the Made in Britain organisation?

“We’re delighted to be a part of the Made in Britain organisation. We are proud of our British heritage, championing local manufacturing and putting Britain on the map. Our company is rooted in the British economy, whether it be supplying the bricks and blocks essential for the housing industry, designing bespoke solutions for our diverse range of customers, or helping our communities prosper. It’s also an honour to sit alongside other British manufacturers, promoting the cause for local manufacturing.” Caroline Wildman, Marketing Director at Forterra.

Where does your company use the official Made in Britain mark?

We use the official Made in Britain mark across our literature, adverts and social posts. It’s a great way to promote that we are a local manufacturer, as the mark is instantly recognisable.

Is there any particular new stories you would like to highlight?

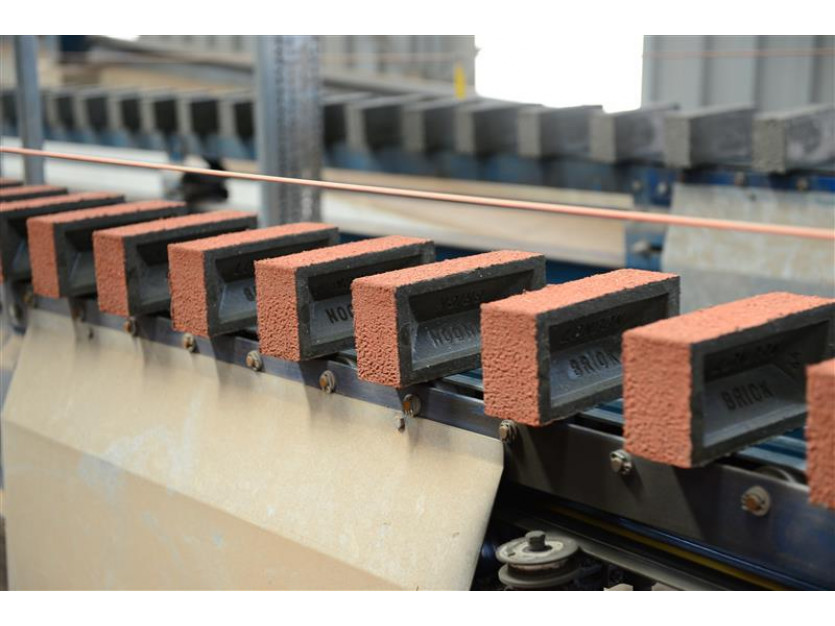

We recently opened Europe’s biggest, most efficient brick factory at our Desford plant. With a total investment of around £95 million, the new factory has been commissioned to grow capacity, improve cost efficiency, and boost sustainability.

Once at full capacity, the Desford factory will be able to manufacture 180 million bricks per annum. That’s enough to produce 25,000 new homes and provide customers with an additional 120 million domestically produced bricks compared to the old factory’s previous output.

The impressive credentials of our new Desford factory demonstrates our commitment to British manufacturing, meeting the ongoing demands of the housing sector and ultimately helping us in our mission in Keeping Britain Building.

For more information

Is there is anything else you consider important and would like to share?

Forterra products can be seen up and down the country throughout residential new builds and period properties as well as major commercial and infrastructure projects.

A recent notable project was Zed House, a flagship zero carbon home concept of Barratt Homes, developed in conjunction with Salford University. It is the first new home in the country built by a major house builder to go beyond the new Future Homes Standard by delivering a carbon reduction of 125%. Instead of standard bricklaying, a mechanical brick cladding system devised by Forterra was used. Originally developed for use on a project with Derby Council to clad for the city’s flood defences, Forterra further developed the system for use in house building, creating larger panels that allow for window and door openings. For more information.

Find out more about the company on their members’ directory profile and on their website.

By Made in Britain 2 years ago | By Made in Britain