TextureJet is pleased to announce the start of an exciting partnership with WMG at The University of Warwick.

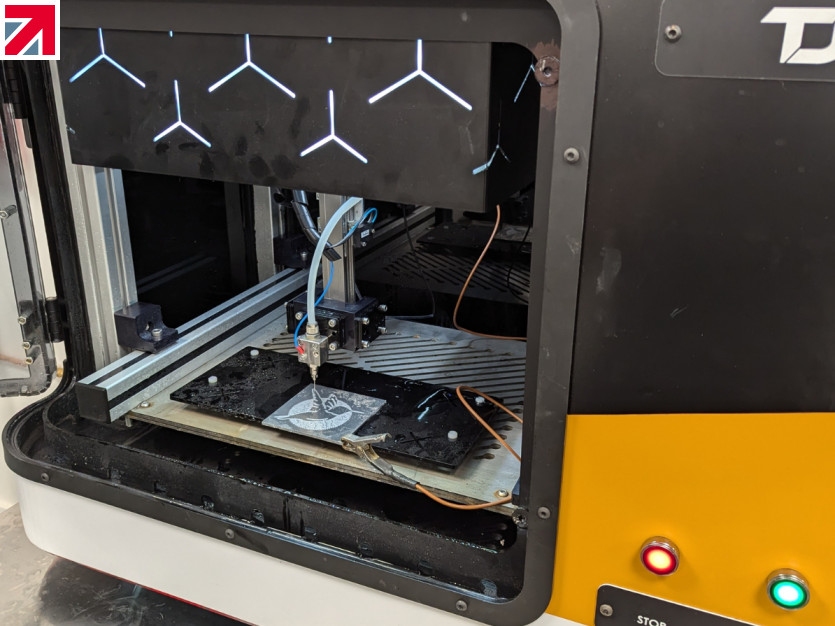

TextureJet has installed two machines, Stat® and Desktop Jet at WMG’s Centre for Imaging, Metrology and Additive Technologies (CIMAT) at The University of Warwick. The technology will be tested and offered to WMG clients for finish work and will be mostly focused on 3D Printed metal components.

Now in its fifth year of business, TextureJet started life as a Nottingham University PhD project. Utilising a highly localised variant of electrochemical machining, known as electrochemical jet machining (EJM), the company is now delivering a tooling platform with world leading capability to selectively change the surface texture of components, resulting in streamlined production lines.

TextureJet is proud to have developed the next generation of targeted and sustainable surface processing technology. Its innovative, globally patented technology can deburr, roughen, polish, pattern, part mark or remove coatings from almost any metal surface.

This attractive alternative to existing technologies results in reductions in factory and toxic footprint, as well as process and operational costs. The process is flexible, easily automated, scalable, and cost-effective, making it an excellent choice for all high value manufacturing industries.

Sustainability is essential for all businesses today, and TextureJet is committed to developing sustainable manufacturing processes that minimize the environmental impact of its customers operations. Its patented surface processing technologies can reduce the amount of waste generated by up to 84% (according to the independent Wood report, 2022).

With global expansion plans, it is an exciting time for the small company. Jonathan Mitchell-Smith, CEO and founder of TextureJet says, “We started as a university spin out five years ago, so it’s great to see our machines in action in a university! We are delighted to be in partnership with WMG and look forward to seeing the first results soon.”

Professor Greg Gibbons, Head of Additive Manufacturing at WMG states “This is an exciting partnership with TextureJet and provides us with a state-of-the-art solution for surface finishing of our metal products, streamlining the post-processing of parts. The technology also opens many opportunities for innovative research in texturing of metal surfaces for applications in, for example micro-moulding; microfluidics and ink-jet printing - allowing controlled fluid flow through surface structuring.”

About Texture Jet

Established in 2019, TextureJet is delivering a tooling platform with world leading capability to selectively change the surface texture of components, resulting in streamlined production lines. Offering an attractive alternative to existing technologies for surface preparation, post processing or creating complex surface geometries, leading to reductions in environmental impact and costs across the process chain.

Find out more about TextureJet: www.texturejet.com

About WMG, University of Warwick

WMG is a world leading research and education group, transforming organisations and driving innovation through a unique combination of collaborative research and development, and pioneering education programmes.

As an international role model for successful partnerships between academia and the private and public sectors, WMG develops advancements nationally and globally, in applied science, technology and engineering, to deliver real impact to economic growth, society and the environment.

WMG’s education programmes focus on lifelong learning of the brightest talent, from the WMG Academies for Young Engineers, degree apprenticeships, undergraduate and postgraduate, through to professional programmes.

An academic department of the University of Warwick, and a centre for the HVM Catapult, WMG was founded by the late Professor Lord Kumar Bhattacharyya in 1980 to help reinvigorate UK manufacturing and improve competitiveness through innovation and skills development.

Find out more about TextureJet on their member profile page here

Member-created content 11 months ago | From members