Nestled in the heart of rural Staffordshire, Statfold Barn Farm is the idyllic home to Statfold Seed Oil Ltd. Since 1992, the internationally successful family business has been producing high-quality organic and natural oils, cold pressed from the seeds from their own farm land, and carefully sourced natural ingredients.

What began as a small seed oil business on their arable farm, the company now has a temperature-controlled ingredients warehouse, an on-site laboratory, a cold pressing seed oil plant, and manufacturing, filling and packing facilities. From here they design, mix, fill and package a wide range of variety of organic and natural oils, and water and oil-based products to nutritional and food markets worldwide.

Recognising the growing cost of dated CIJ technology

Statfold Seed Oils had long been applying codes to their products using a continuous inkjet printer (CIJ). Whilst it had served them well in their earlier years when production runs were smaller, their dated CIJ system was struggling to reliably print codes onto around 10,000 labels per week. The system was expensive to run and ink management was particularly messy. It was also difficult and costly to service, made more so due to it being a discontinued system.

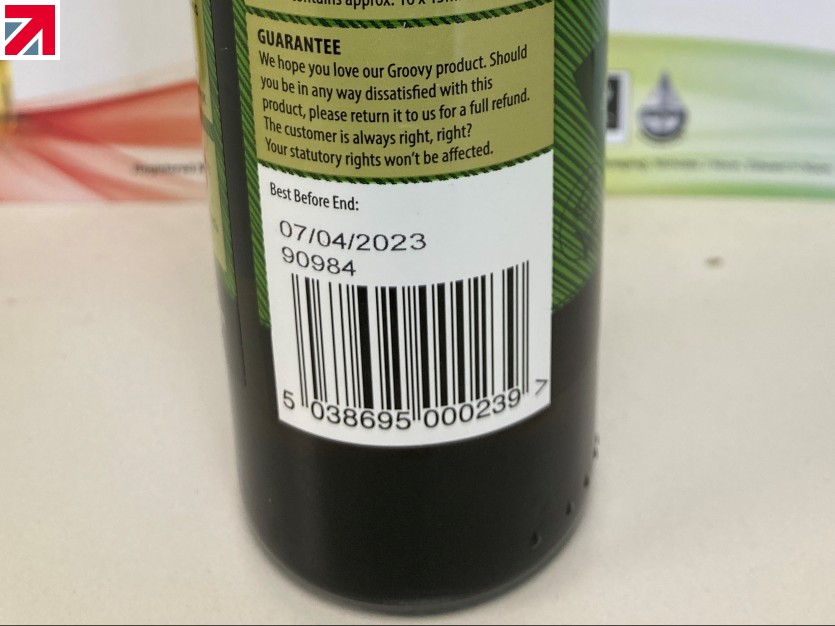

The company print batch codes and best before dates onto a wide range of products, including plastic and glass bottles ranging from 50ml to 500ml. Having recently invested in a new wrap around Premier Labelling System, they needed to find a far more efficient and cost-effective alternative to CIJ – one which would equal the print quality of the CIJ, cope well in their packaging environment, and work in conjunction with their new labeller.

Thermal inkjet delivers on all of the essential ingredients

Having contacted Rotech for advice and help with choosing the right solution, sales manager Steve Ryan assessed all of their needs and recommended installing an Integra One thermal inkjet printer. The printer, despite being small enough to hold in one hand, is incredibly powerful and flexible, and solves all of the outlined problems:

- Integrates seamlessly with the labelling system

- Can easily be moved to any part of the packaging line

- Ink is contained in a simple ‘click in’ ‘click out’ cartridge

- Produces high-quality prints up to 900dpi

- Prints at speeds up to 180m per minute

- Can be used in almost any environment

- Low consumable costs – one cartridge can produce up to 400,000 prints

- Includes format creation software

- No maintenance costs

Software designed to offer coding freedom and flexibility

In addition to meeting all of the needs of the Statfold Oils team, the Integra One also comes with its own iDesign format creation software. The user-friendly control panel allows users to create and edit date and code formats, as well as setting batch code sequencing.

The software also allows them to set codes, text or images at up to 12.7 mm in height, which is ideal for their custom designed products.

Along with total print flexibility, the software also provides information on job status, print quality and ink levels.

Read the full case study here

“We currently use the printer to print batch codes and best before dates on a wide range of products; plastic and glass bottles ranging from 50ml to 500ml. The Integra One has been fitted to our brand-new Premier Labellers P120 wrap around label machine, and we have been getting very good speed and quality out of both machines, approximately 10,000 bottles labels per week.

We have built a great relationship with Steve Ryan. The support and customer service are excellent. We did experience some issues with printing onto a new style shiny label. Samples were sent to Steve and Rotech ran them through their test bed and recommended a different ink cartridge. This was turned around in 2 days, minimising production down time.

The units themselves are smaller, easy to use and cost effective compared to other batch coders that we use on site. Plus, consumables costs are also significantly less. The cost is a bonus but for us, the quality must be perfect for the customer.”

If you have a similar application, or you would like to speak to one of our experts about how you could benefit from using thermal inkjet technology, please contact us

Find out more about Rotech Machines Ltd on their member profile page here

Member-created content 4 years ago | From members