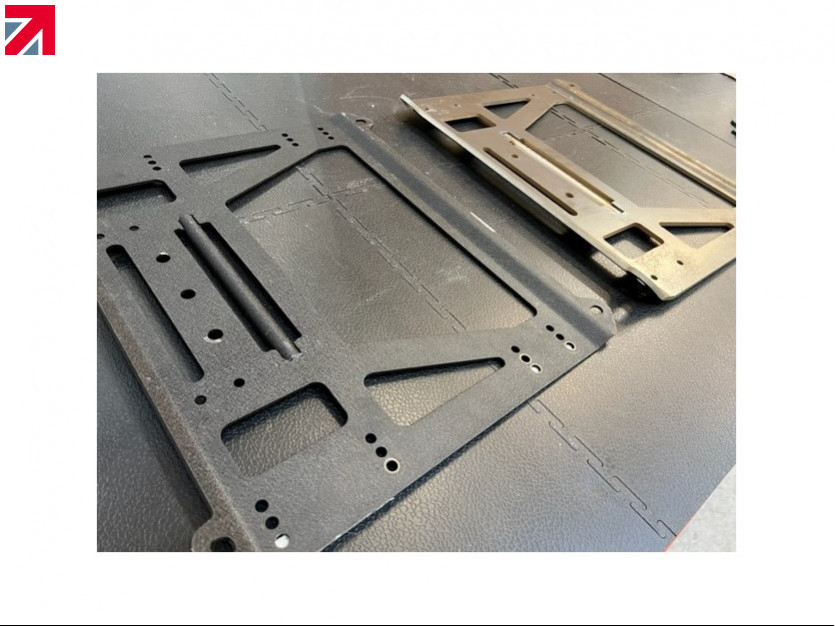

Unparalleled Precision Waterjet Cutting

Aqua Dynamics is a family run business with over 20 years CNC waterjet experience. Delivering a unique subcontract service, specialising in waterjet cutting and precision waterjet profiling.

Utilizing the latest OMAX waterjet cutting technology, we're capable of producing unparalleled quality work quickly and efficiently. We are fully accredited to ISO 9001:2015; quality service is guaranteed. We can accommodate all materials up to 180mm thickness using high-pressure water (60,000 PSI) with abrasives to achieve premium results in all materials.

Waterjet is one of the most versatile cutting processes available to all industries including film, construction, aerospace, motor industries, stone masonry, defence, architecture & design to name a few. Well suited for high-performance cutting of all materials. Waterjet technology, when used with or without an abrasive additive, creates a clean cut that doesn't require any secondary finishing and produces NO heat effected zone. Softer materials may require minimal deburring but nothing more.

Primary benefits include:

· No heat affected zone

· High-precision, complex cutting

· Abrasive & Non-Abrasive cutting

· Environmentally friendly

· No compression distortion

· NO harmful by-products

· Easy Programming

· Heat Input: None (cold process)

· Material thickness: <180mm

· Accuracy: +/- 0.02mm

· 60,000 PSI

· Tilting head

· 2D & 3D parts cut

· Latest Omax technology

· Maxi & Mini head capabilities

Abrasive waterjet cutting has no limitations when it comes to the materials it can cut, with the rare exception of toughened glass.

With its cold cutting process, all heat exposure is bypassed, which is especially critical for materials like metals, leading to a fine cut without distortion in the material. This results in a smooth and burr-free cut.

Our precision Omax waterjet machines can cut the following materials (among others) to tolerances +/- 0.02mm:

· Acrylic

· Aluminium

· Brass

· Bronze

· Carbon Fibre

· Ceramics

· Composites

· Copper

· Plastics

· Steel

· Stainless Steel

· Titanium

· Wood

· Foam

· Kevlar

· Glass

This environmentally friendly approach to engineering is not only efficient but also allows for complex designs to be achieved in all materials.

Please contact us in our brand-new Oxfordshire based workshop with any enquiries you may have, large or small batches catered for, lead-times to suit.

File formats - dxf, dwg, pdf or hand drawn, dimensioned designs if this is all you have.

This environmentally friendly approach to engineering is not only efficient but also allows for complex designs to be achieved in all materials.

Please contact us in our brand-new Oxfordshire based workshop with any enquiries you may have, large or small batches catered for, lead-times to suit.

File formats - dxf, dwg, pdf or hand drawn, dimensioned designs if this is all you have.

Find out more about Aqua Dynamics Ltd on their member profile page here

Member-created content 2 years ago | From members