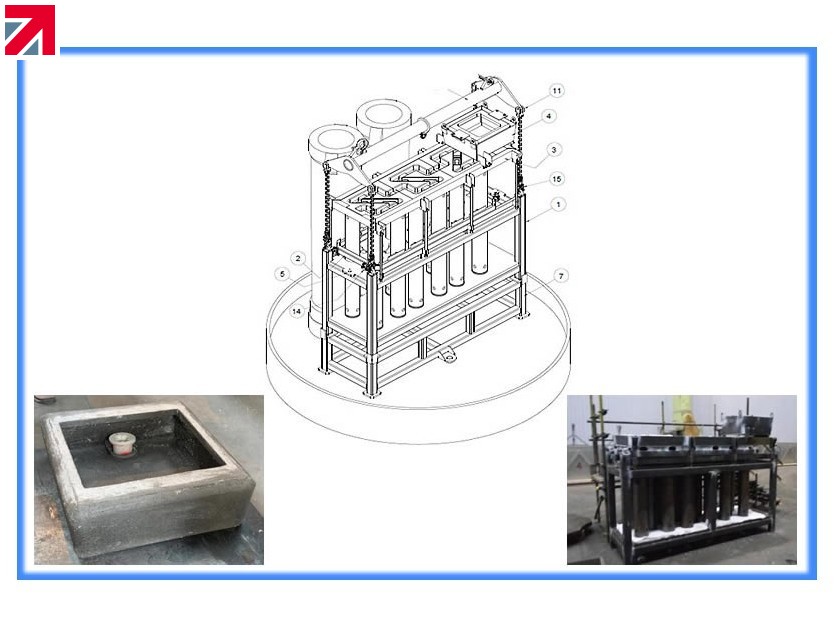

Innovation within our industry sector continues at a rapid rate with new technologies, processes and standards advancing each year. Trent Refractories are starting the year with a case study that demonstrates innovation at the highest levels. Our client has an established process manufacturing large diameter, nickel super-alloy ingots using a Vacuum Induction Melting (VIM) process.

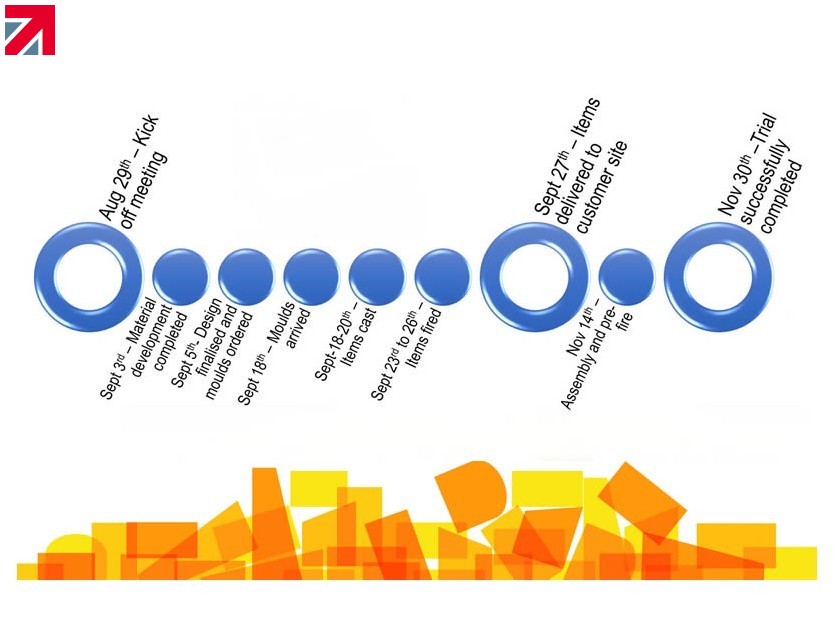

Trent Refractories were invited to participate in a feasibility study investigating manufacture of smaller, diameter sticks by supplying a proto-type catcher box. The project required material development, engineering, design, mould fabrication and external firing to 1000°C. The timescales for delivery were set at three weeks and the collective team delivered the solution allowing for a trial period which was viewed as a success by the client. Refractories innovation at its finest.

Find out more about Trent Refractories Ltd on their member profile page here

Member-created content 3 years ago | From members