According to the UN environment programme Global Status Report for Buildings and Construction, the buildings and construction sector is not currently on track to achieve decarbonization by 2050. With the gap between climate performance of the sector and the decarbonization pathway widening, John Lawrie Tubulars is continuing to diversify its products and services to offer a wider range of sustainable, carbon saving products to a growing number of industries.

As a business we are working hard to do what we can to support the construction industry, who’ve been targeted with making near-zero emission and resilient buildings the new normal by 2030. The Buildings Breakthrough initiative was launched at COP28 last November in Dubai, to strengthen international collaboration in relation to decarbonisation.

Hitting these demanding carbon targets will call for systemic change. Organisations such as the UK Green Building Council and the ASPB recognise that circular economy strategies, practices and products are crucial to hitting carbon reduction targets and mitigating further climate change.

The key principles of a circular economy are to:

- design out pollution and waste

- to keep materials at their highest value for as long as possible

- to be regenerative and restorative, or in other words to be better rather than less bad; for example cleaning up a river in addition to not polluting it.

To bring about the systemic change needed, we must shift away from business as usual and change mindsets. Buying a reusable coffee cup, having meat-free Mondays or walking to work once a week simply isn’t enough to meet Buildings Breakthrough targets in the next six years.

What do we do to support the Circular Economy and Net Zero Targets of the Construction industry?

John Lawrie Tubulars repurposes surplus steel pipe from around the globe. This saves CO2 emissions that would be generated by the returning of the surplus pipe to steel mills for re-melting, a process that includes transportation, handling, and cutting to re-enter the melt stream.

Following the completion of a life cycle assessment in 2020, we can now show that for every ton of John Lawrie Tubulars repurposed steel pipe, there is a CO2 saving of over 2.163 tonnes when compared to the production of new prime steel. This goes a long way to supporting net zero and sustainability goals for both our clients and our suppliers.

We have worked hard over the last 30 years to streamline our business and strategically position our yards to minimise unnecessary transportation. We are now perfectly positioned to increase our foothold in Europe and work with even more businesses to reduce CO2 emissions.

Embedding circular economy in Construction

We understand that the circular economy needs to be embedded in the way buildings are designed, used, and redeveloped.

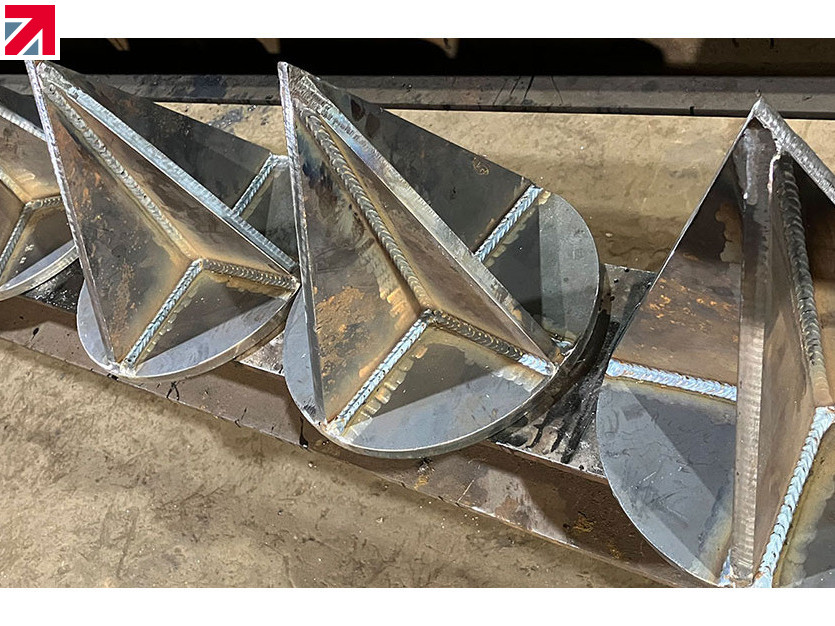

Where redevelopment or refurbishment of existing buildings is not possible, we must build new ones, those buildings need to be designed in sustainably, using lower carbon products. For example, why continue to use concrete piling just because that is what has always been done? Why not try a sustainable alternative such as repurposed top driven steel piling or Helical Piles which are made in the UK?

Repurposed Steel Tubulars are made from robust tensile steel, adaptable and long lasting, and save 2.163 CO2e per tonne of steel product (when compared to newly milled steel.

We have worked hard to educate our clients, their design teams, contractors and subcontractors to understand how they can make reuse work. Our whole value chain works together, we’re keen to ensure that reuse becomes the new normal.

If you are keen to hear more about how we can support your construction project with repurposed steel tubular products get in touch. We are keen to talk to engineers, architects, designers and clients (new and existing) to understand how you incorporate reuse in both your designs and your procurement processes.

We will continue to build on the diversification of our repurposed steel products and services, to offer you a cost-effective sustainable solution for your business whilst the price of new resources continues to increase and carbon targets become more significant.

Find out more about John Lawrie Tubulars on their member profile page here

Member-created content 1 year ago | From members