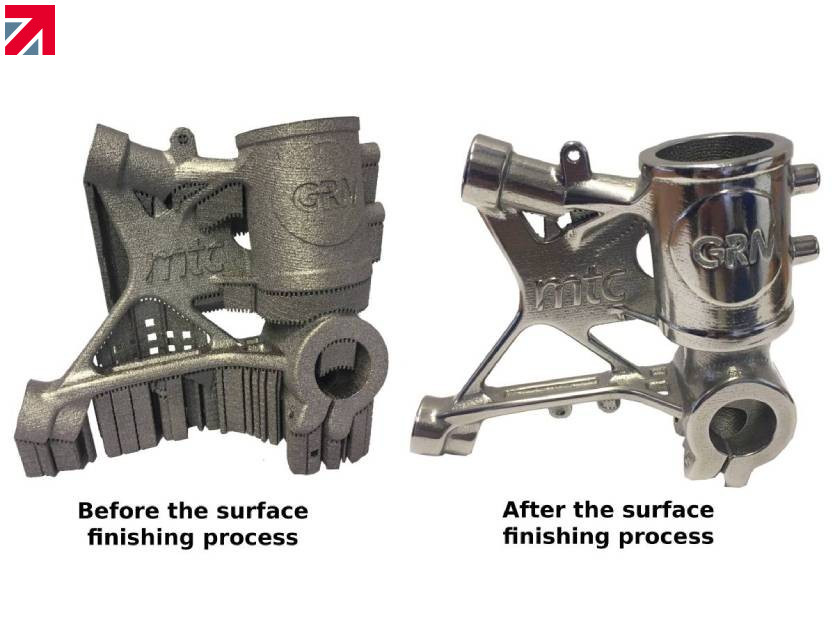

In order to improve the appearance, surface roughness and mechanical properties of additive manufactured parts, 3D printing post processing remains an important factor.

Additive Manufacturing (3D Printing) is now an established technology for prototyping and mass production. However metal parts that have been produced through additive manufacturing tend to have a surface with an average Roughness (Ra) ranging anywhere from 10 to 30 microns. The values of Ra may increase at support locations and may decrease depending on the geometry profile.

In order to improve the appearance, surface roughness and mechanical properties of additive manufactured parts, 3D printing post processing remains an important factor. Selecting the most suitable surface finishing technology is critical to prove the viability of components from a cost and functional standpoint. In an ideal world, surface finishing must be considered when designing components for AM to ensure the desired component and its characteristics can be achieved.

Innovative 3D Printing Post Processing Solutions from ActOn

3D printed parts require post processing to remove powder and support structures, achieve a smooth surface and a polished finish. At ActOn Finishing we have developed cost effective technology and a series of automated mass finishing processes to surface finish additive manufactured components in a short time.

For a powder-based metal additive manufacturing process, first step often involves removing the powder residue left from the 3D printing process. The AM Blasting technology is perfect to remove powder, even from parts with complex geometries, in an efficient way. The AM DI depowdering system is developed for manually cleaning of powder bed printed parts and it is suitable for blasting of individual, large parts.

Next step in the 3d printing post processing includes surface finishing and polishing the 3D printed components. For this stage we recommend the ActOn CHEF technology. The CHEF Machines are the fastest finishing machines on the market to reduce surface roughness, deburr and polish 3D printed parts. In many cases, the results achieved via CHEF systems cannot be achieved in a standard vibratory process, particularly applications that include achieving a high level of surface finish or a high rate of defect removal. Moreover, the CHEF machines can be 10 times faster than traditional finishing methods and produce superior finishes. It is one of the most efficient batch finishing methods.

The action of these machines relies on the high force and speed at which the media chips come into contact with the processed components. The forces can be as great as 15-20 times the force of gravity, depending on the rotational speed and the turret size of the centrifugal machine.

ActOn’s Cost-Effective Surface Finishing Process for SLM 3D Printed Parts

At ActOn we worked closely with The Manufacturing Technology Centre (MTC) to develop an optimum 3d printing post processing solution which benefits the industry by reducing processing times and producing a repeatable and quality AM component.

The AM parts have been built using SLM or EBM processes, from materials like Ti6Al4V. Hence these required intensive manual finishing, to remove support structures and to smooth down rough surfaces. Our objectives included:

Identifying a cost-effective finishing process for the external surface of the part

Develop a finishing process for the internal surface of the part.

We started by carrying out trials where it has been determined that the most efficient equipment is ActOn’s CHEF machine to achieve sub 1μm RA surface finishes. Then The MTC has acquired an ActOn CPM-10 model and ActOn’s consumables to undertake in-house development. Further trials have been conducted by both teams to determine the optimum machine parameter settings to process additive manufactured materials like Ti6Al4V.

The Result

- We achieved a Ra of sub 1μm in 5 hours, 80% faster than traditional finishing.

- Achieved a Ra between 2μm to 3μm in approx. 30 minutes.

- 46% cost savings on the finishing process.

- From reducing surface roughness, to deburring and polishing these are just a few of the applications that have been achieved via the high energy finishing process.

- The project provided further information regarding surface finish parameters, component weight loss, media weight loss, effectiveness of using media with different abrasive grades and hardness.

Ruaridh Mitchinson, Research Engineer at The MTC comments:

“The CPM-10 has provided invaluable insight into finishing both EBM and SLM AM parts. This has provided the MTC with a low cost means to efficiently and effectively conduct R&D into surface finishing of additive manufactured parts.”

We hope this has helped you to gather a better understanding about surface finishing for metal 3D printed parts and how optimal results can be achieved. To find out further information or to organise your free processing trial, please contact our technical team.

Find out more about ActOn Finishing Ltd on their member profile page here

Member-created content 4 years ago | From members