Sifters (Centrifugal Screening)

Manufactured by Hanningfield Process Systems Ltd.

Product Buying Options

Product Capacity: Up to 23,000 kgs/hr

Product Description

Design & Operation

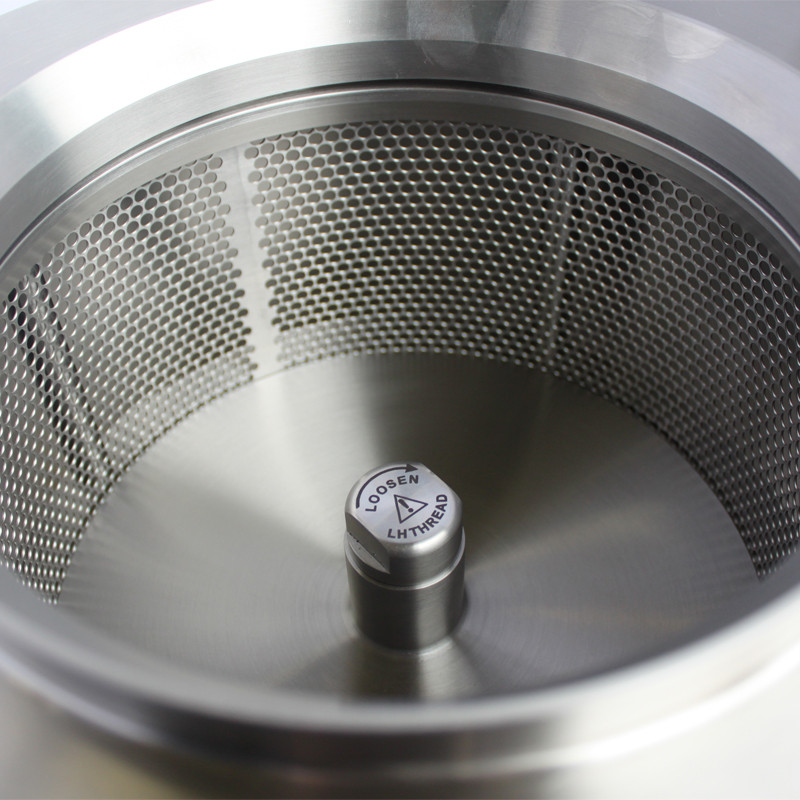

The Hanningfield Kwik-Sift offers fast and effective powder screening, helping guarantee material integrity through the capture of alien objects (such as nuts, bolts, washers, cable ties). The rotating mesh drum creates a centrifugal screening action, with powder passing through the mesh while retaining those objects larger than the hole aperture. For achieving different grades of separation, various drum mesh sizes are available to meet different application requirements.

The unit can incorporate a single or dual spoiler arm arrangement for performing simple de-lumping of agglomerated material. The spoiler arm simply clamps onto the existing chute via a tri-clover.

Construction

As standard, all contact parts are manufactured from 316L stainless steel (180 grit), with FDA compliant seals, gaskets etc. Non-contact parts such as frames, motor covers and control panels are manufactured from 304 stainless steel (150 grit).

All standard materials of construction and surface finishes can be upgraded or downgraded upon request.

Customise Your Sifter

Various mounting solutions are available for the sifters (mobile frame, swing-arm, fixed post, hoist mounted etc.) and it can be customised with a selection of inlet and outlet configurations including hand-feed chute, valve assemblies, tri-clover connections, vacuum adaptors or any other bespoke design required for process integration.

Documentation

All equipment can be supplied with full validation documentation (FS/DS, FAT, SAT, IQ/OQ) and 3.1 mill certificates to EN10204.