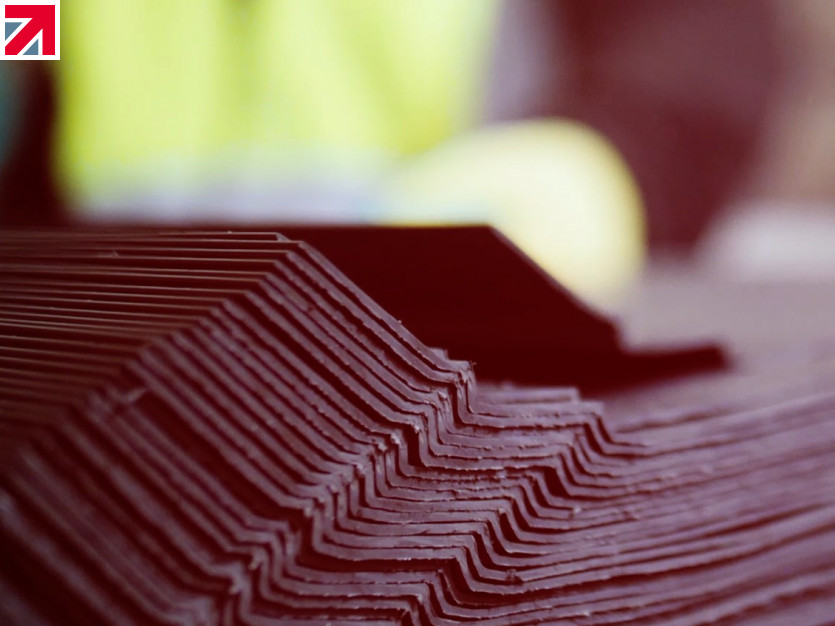

We are a true British manufacturer, with 82% of our plastic products made in-house. We provide the construction industry with materials that are fit for purpose. Our roofing and building range includes:

• Dry fix ridge and hip kits

• Dry fix verge units and accessories

• Eaves level ventilation including felt support trays & over fascia vents

• Cavity insulation products

• Underfloor brick ventilation systems

Our focus is quality, quality, quality. We never waiver from it. Gaining our customers trust is the most important thing to do for our brand identity. So, to compromise on this is something we aren't prepared to do. We all know that reputations are ruined by poor workmanship and use of inferior products. Especially in the construction industry. So what are the benefits of buying British made? Well, take one of our first, and best-known products - the dry fix ridge kit. Available in various sizes and colours, the kits are:

• Certified and verified from an independent testing group

• Tested in-house through various quality control channels

• British manufactured at our Lancashire site

• Guaranteed for 20 years on all components

• Compliant to BS 5534, BS 8612 and BS 5250

• Accredited to ISO: 9001:2014 Manufacturing Standards

Manufacturing really is the heart of our business. We are proud to be a true British manufacturer and want to shout about this. That is why, throughout November, we are celebrating all things manufacturing. Through a series of social media posts, we aim to raise awareness of the Easy-Trim group with:

• Product spotlights

• Facts & trivia

• Staff interviews

• Sustainability & recycling articles

• A focus on innovation & technology

• Plus much more....

If you want an insight to our wonderful world of plastic production, follow us here:

LINKEDIN https://www.linkedin.com/company/3126216/admin/

FACEBOOK https://www.facebook.com/EasyTrimRoofingandConstruction

Go, UK manufacturing!

Find out more about Easy-Trim Roofing & Construction Products Ltd on their member profile page here

Member-created content 2 years ago | From members