Achieving a high-quality surface finish for components is crucial, especially for those that require extreme precision and sealing capabilities. Traditionally, the most common solution has been a combination of lapping and polishing processes, which can lead to a side effect called roll-off, resulting in the removal of sharp edges from the components.

Roll-off occurs when the component sinks into the polishing pad material during the polishing process, causing the edges to be softened by the nap of the pad. The impact of this phenomenon becomes more apparent as the component remains on the polishing pad for an extended period. Therefore, it is crucial to strike a balance between the speed of the lapping stage and the resulting surface finish to decrease the time spent on the polishing pad. However, it is becoming more common for a component designer to ask for the sharp edges to be maintained, particularly on sealing components where roll-off would cause parts to leak.

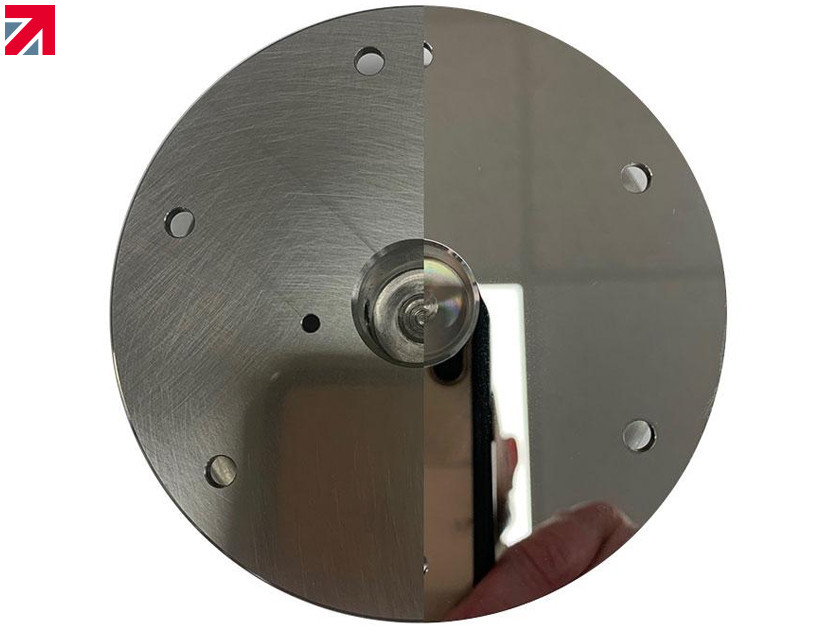

Kemet has developed a new composite plate material named PR3 to tackle this problem. When paired with Kemet's accurately graded Liquid Diamond slurries and Diamond paste, the PR3 plate material can create a surface finish that surpasses the outcome of only polishing, all the while retaining the sharp edges of the component. Additionally, the PR3 has the ability to remove material at the same time, making it an efficient solution for achieving both a high-quality surface finish and maintaining the sharp edges.

The composite's low metal content makes it well-suited for use in industries such as nuclear and electronics, where it is necessary to prevent components from coming into contact with metals. Moreover, the use of ceramic-faced conditioning rings along with the PR3 plate ensures that parts are much cleaner after lapping, particularly white aluminium oxide-based ceramic materials.

Due to the excellent surface finish achieved by the PR3 on various materials, a pad polishing stage would be unnecessary. However, in circumstances where secondary pad polishing is needed, the polishing time is short enough for no roll-off to be produced.

Kemet provides complimentary testing for all lapping or polishing applications, irrespective of whether you already have a process in place. With the development of the PR3 composite plate material, component designers can now achieve a high-quality super finish while maintaining sharp edges, making it an ideal solution for sealing components and applications where metal contact must be avoided.

Contact sales@kemet.co.uk for further details.

Find out more about Kemet International Ltd on their member profile page here

Member-created content 2 years ago | From members