NorthWest GRP and Carbon Fibre manufacturer AllScope Projects are pleased to report dedicated energy efficiency measures has reduced their carbon footprint and increased orders.

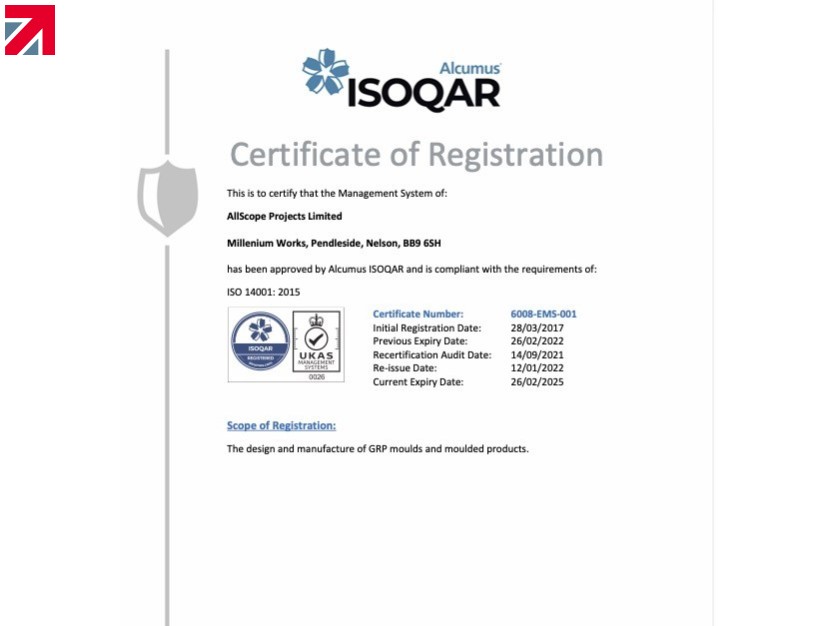

In line with ISO14001:2015 environmental accreditation and the company’s own personal goals to reduce waste, AllScope Projects have completed an energy usage reduction project with a number of new initiatives in the pipeline.

The first investment has seen the transition from traditional strip lighting within 10,000sqft of manufacturing and office areas, to more efficient LED lighting.

General Manager Michael Davies explained “As with any business, we are always looking for opportunities to create safe and efficient savings throughout our manufacturing processes and business activities”.

“We have held the ISO14001:2015 environmental accreditation standard for four years (plus the previous 2008 standard), so with this, combined with our own annual internal health and safety review, we identified there may be advantages to reviewing our lighting and energy usage to reduce our carbon footprint.”

“Starting with our energy consumption, we found there was potential for considerable kw/h energy usage savings. It then transpired other benefits included health and safety improvements with LED lighting significantly improving the working environment for our dedicated employees”.

“As a business we have increased our client work and output, but seen a dramatic reduction in our kw/h usage. Whilst energy prices have continued to rise, we have seen a slight reduction in cost, however with our main objective being to reduce our carbon output, we are very pleased with the results”.

Supply Chain Benefits From Carbon Footprint Reduction

Michael continued, “As a GRP manufacturer we work with a number of sectors focussed on reducing their carbon footprint in line with legislation, their own industry expectations and business values”.

“It is important for AllScope Projects as a business, that we demonstrate not only our GRP and Carbon Fibre manufacture capabilities, but how we as a supplier can support clients to achieve their environmental objectives”.

“For example, we have 3 blue-chip transport manufacturing clients, both in the UK and worldwide who face tough challenges and deadlines from governments in reducing their carbon footprint.

“As a supplier to them, they have acknowledged our initiatives have contributed to reducing supply chain environmental impacts, which has led to AllScope Projects securing additional contracts and project extensions”.

“We have seen several manufacturers announcing their commitments to producing all electric vehicles. Jaguar are the latest to announce they will be an all electric brand within 5 years”.

“We are keen to talk to other businesses that recognise they need to make changes within their production, procurement material sourcing and supply chain to make positive impacts.”

Find out more about AllScope Projects on their member profile page here

Member-created content 3 years ago | From members