Overcome challenges with an automatic, persistent and simple steam trap monitor

Steam systems are utilised across many industries from basic chemicals to food and found in many sites for district heating and hot water needs. If you rely on steam, then you probably have many steam traps in your infrastructure. They are vital for efficient and safe operation but susceptible to problems. Furthermore, steam traps can be in difficult locations, such as confined spaces, making manual testing time consuming and hazardous. That’s why we are focusing on three challenges that steam trap users face and how DCO Systems’ steam trap monitor is overcoming and eliminating them.

Eliminate tedious manual testing with automation

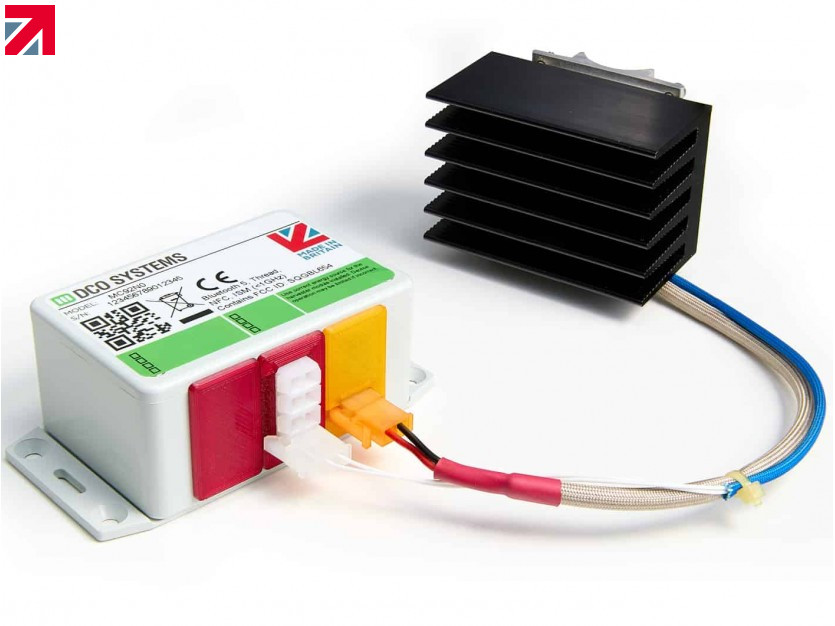

Manual testing is not only time-consuming, but it can also pose a safety hazard for personnel. Since many of the traps installed are found in difficult and inaccessible locations a low maintenance solution is important. DCO achieves this by offering a solution that eliminates the requirements for power cabling installation and for regular battery maintenance. Each installed monitoring unit has a power harvesting module included that provides a local source of energy derived from high temperature pipework (condensate or steam). The steam trap monitor is easily retrofitted to the adjacent pipework and collects performance data round the clock in a targeted resource-efficient manner. Instead of the engineer seeking the data, the data is automatically sent to them.

Diagnose problems persistently & accurately

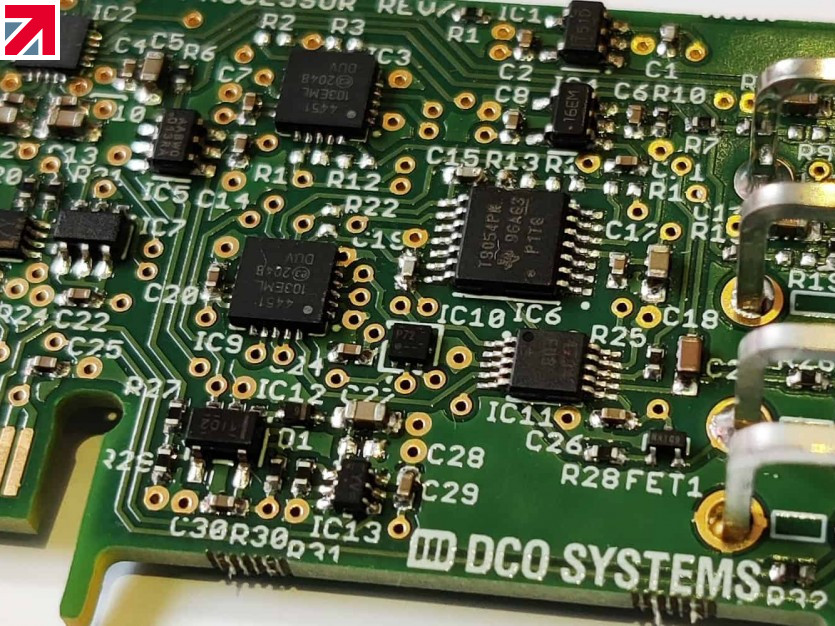

Sensing probes enable the steam and condensate sides of the trap to be monitored. Automation of existing monitoring techniques allows trap status to be diagnosed through a combination of temperature and ultrasound analysis. Temperature analysis on its own, when readings are frequent and automated, can be used to diagnose many operational conditions, such as “cold traps”, but the combination of temperature and ultrasound introduces maximum certainty and reliability to automated diagnosis. Furthermore, persistent monitoring of the trap builds a picture of the real-world performance of the device that is much more complete than is possible with point-in-time checks done manually.

Pinpoint failed traps simply & efficiently

Failed closed (“cold”) traps are more easily missed in manual monitoring due to the long intervals between measurement and the possibility that assessment may not align with the operational period of the trap. Drip leg traps are particularly prone to be being missed for such checks as they are often smaller and often hidden away or harder to access than larger process equipment traps. An installed DCO steam trap monitor can recognise changes in temperature profile over time to allow the scheduling of preventative maintenance. As a result, remedial action can be taken before a trap fails completely. Compared to manual testing this approach is simple, efficient, and can be applied to any type of trap.

DCO Systems’ self-contained steam trap monitor is automatic, persistent and simple. Manual on-site monitoring is greatly reduced and the need for personnel to routinely check traps in inaccessible and hazardous locations is eliminated. Performance data is analysed in real time to identify current and historical issues and that analysis is used to schedule maintenance and repair activity in a targeted resource-efficient manner. To get started with DCO’s affordable monitoring tools, go to dcosystems.co.uk, email: info@dcosystems.co.uk or call: 01285 359059.

Find out more about DCO Systems Limited on their member profile page here

Member-created content 4 years ago | From members