Major investment at the Cheshire factory of Clarke Cable, the UK’s leading manufacturer of cable assemblies and ‘plug and play’ interconnect systems, will significantly expand production capacity, as the company enters its 50th year of operations on the back of an impressive period of growth.

The investment builds upon the company’s philosophy of continuous improvement and development, coming on the back of the recent acquisition of the wire harness manufacturing business of Stacey (Europe) Ltd, which has hugely diversified Clarke’s product offering and strengthened ties with OEM’s, distributors and retailers in the automotive and renewable energy industries especially.

Sustainable Growth

The arrival of two new 30 tonne injection moulding machines, a new compressor system and super-efficient industrial chiller set-up, three further cable cutting and winding machines, plus a raft of new electrical test equipment, all forms part of a makeover plan that will boost the number of production lines available in simultaneous operation at the Congleton site, reduce lead-times and allow for greater flexibility and efficiencies, all designed for a better service and increased support for customers.

With year-on-year final quarter growth of 68% in 2021, and January 2022 already being Clarke’s most successful trading month to date, the expansion hasn’t been limited to technology, with new roles being created across the business to ensure that growth continues in a sustainable manner. Recent hiring and internal promotions have seen a new Operations Manager, Production & Quality Supervisor, Production Team Leaders, and Sales & Marketing Administrators all now in post for 2022.

Over-mould expertise

Clarke Cable are experts in component over-moulding, offering innovative solutions to increase the durability, reliability, and overall lifetime of cable connectors and components designed for use in even the most extreme environments and terrains.

With the site now holding a total of 25 top-spec injection moulders to produce Clarke’s market leading y- and tri-splitters, connectors, grommets, plugs, and custom over-moulds, expect Clarke Cable to remain the go-to manufacturer for British made bespoke, industry standard, and specialist-application cable assemblies for the foreseeable future.

Key Supplier

Clarke Cable products find use in an almost limitless range of industries and applications, wherever the need for electrical power or data connectivity arises. With an extensive list of approvals, as well as internationally recognised quality management systems and product specifications, Clarke Cable acts as a single source supplier to the global manufacturing market. As a key supplier of antimicrobial cable and critical device connections to the NHS, and a major supplier of site lighting solutions to the MOD, Clarke’s production site remained open and active throughout the pandemic to support those frontline services most in need. The company is a committed member of Made in Britain and is proud to be playing its part in the rejuvenation of the UK manufacturing industry. With 50 years of knowledge, experience and quality service behind them, Clarke Cable continue to go from strength to strength.

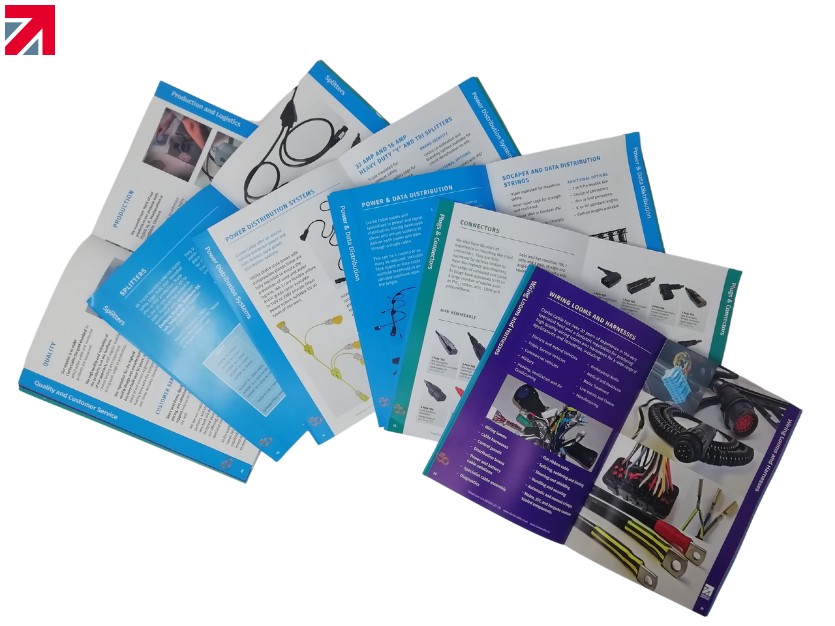

To view Clarke Cable’s 2022 Catalogue please click here: Clarke Cable Ltd 2022 Catalogue

For further information or any enquiries, please visit/contact:

www.clarkecable.co.uk

alastairc@clarkecable.co.uk

01260 272132

Find out more about Clarke Cable Ltd on their member profile page here

Member-created content 3 years ago | From members