Cornwall-based Fishy Filaments, the world’s first recycler to transform end-of-life fishing nets into high-value materials for 3D printing and injection moulding, is launching its latest Crowdcube campaign to fund the next phase of its award-winning growth.

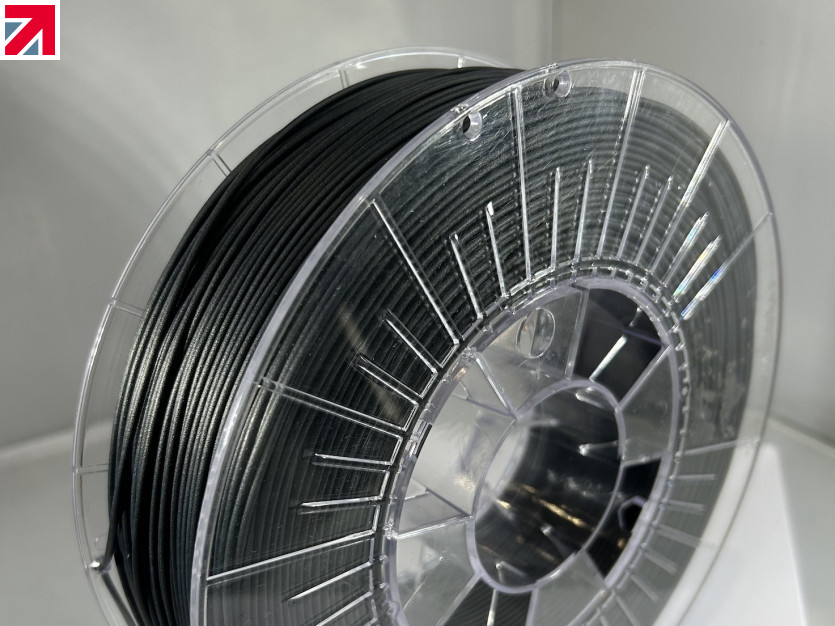

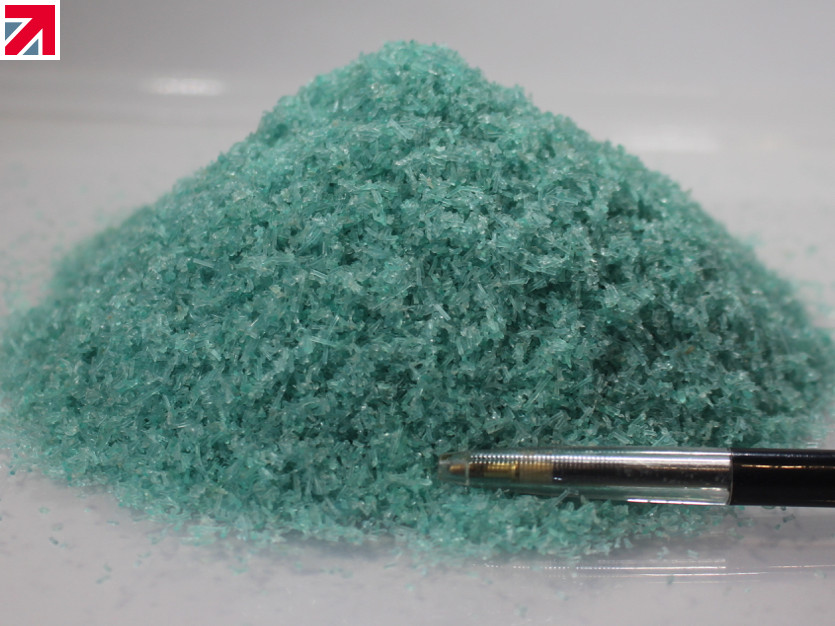

Targeting £150,000, the raise will be used to expand, develop, and market Fishy Filaments’ range of high-value filaments and pellets. This will also include the launch of the world’s first commercially available 100% recycled carbon fibre reinforced nylon 6 powder for use in advanced Selective Laser Sintering (SLS) 3D printing.

These powders have the potential to transform the economics of its current operation.

Set up in 2016 to recycle old Cornish gillnets into virtually carbon free marine nylon for use in advanced engineering and manufacturing, Fishy Filaments is providing a vital second life solution for end-of-life monofilament net; a problem and costly waste.

Globally, 200,000 tonnes of end-of-life nets are either burnt, buried or discarded at sea each year. Nets that are burnt release vast amounts of CO₂, while nets that end up in the sea represent a significant and long-lasting danger to both wildlife and shipping as ‘ghost nets’, taking up to 600 years to biodegrade. Fishy Filaments’ recycling plants will have the ability to address this issue by providing a better end-of-life solution.

Providing a fully traceable source of near carbon neutral materials that can be used in everything from the fashion industry to the automotive sector, Fishy Filaments’ recycled materials are in high demand.

By delivering performance parity with virgin Nylon 6, but with 97-98% less CO₂-eq emissions, Fishy Filaments is creating a new means to tap into the global recycled monofilament fishing net market. This has allowed the company to radically revalue the global revenue potential of that market from around US$150m per year up to US$6bn, of which around US$1bn per year could be directed to the communities that operate its localised recycling plants.

Aided by its new line of high-performance carbon fibre reinforced SLS 3D printing powders, which have the potential to realise a per kilo sales price more than five times that of its other profitable product lines, Fishy Filaments is further widening its markets.

Commenting on the fundraise Ian Falconer, Founder and CEO Fishy Filaments, said: “We are at a very exciting point in the growth of Fishy Filaments. We have a proven range of products, an advanced R&D program, and an established and growing base of loyal international customers ranging from Philips Lighting to Mutiny Shaving.

“We’ve undertaken trials or studies with multiple blue-chip customers including L’Óreal, Prada, Ford, and Daimler-Benz, and are currently participating in trials with other major automotive players including BMW. Here, high-performance components that are co-recyclable and allow for Scope 3 emissions to be addressed in novel ways are seen as highly attractive.”

Falconer added: “Our next step is to advance the development and marketing of our next generation of 0rCA® carbon fibre reinforced filaments and powders. This will include the launch of the world’s first 100% recycled nylon PA6-CF powder, which is optimised for the highest level of performance in SLS 3D printing.

“Used to create a vast range of products, parts, and components, these powders represent a market gamechanger and will play a key part in feeding both the growth of the business, and our wider global and social ambitions. This is why our latest Crowdcube fundraise is so important. It holds the key to unlocking a future with global impact.”

Turning a problem waste into an economic asset, Fishy Filaments is working towards a future where fishermen in unregulated parts of the world will be able to recycle their nets locally using a network of Fishy Filaments’ plants. Fitting into a 40ft container, these plants can be transported to remote parts of the world, requiring only water and power to operate.

Providing a new income stream for fishermen in these regions and an environmentally sound alternative solution for fishing net disposal, the materials arising from Fishy Filaments’ process have the potential to displace 2m tonnes of CO₂-eq emitted by new Nylon 6 production each year.

Where fishermen have to pay for the safe disposal of their nets, Fishy Filaments’ aims to provide fishing fleets with a zero-cost recycling solution. This is something that it is already doing for the Cornish hake fleet in its home port of Newlyn.

Saving the fishing fleet hundreds of pounds a year for every tonne of net recycled, its solution simplifies operations for harbour operators, and reduces the volume of net sent to landfill, incineration, or for conventional but costly recycling.

Following recent funding, Fishy Filaments is currently scaling its business into full commercial production and is building the first three modules of its fully automated fishing net recycling plant prototype at its Newlyn base.

Aided by a £126,000 loan from the British Business Bank-backed SWIG Finance, and a recent cash grant of almost £50,000 from Cornwall Council’s Growth Hub* this automated plant will increase raw material production levels to 20 tonnes per annum in the next year, and then on to 50 tonnes a year.

Beyond this, Fishy Filaments’ aims to scale up its global operations by selling its proven, profit making, chemical-free recycling plants to NGOs, local governments and entrepreneurs internationally; building a network of production centres in coastal communities around the world.

Incorporating off-take agreements for recycled materials that are produced at these plants, this approach will provide a guaranteed and stable per kilo price to plant operators, and will deliver social, economic and environmental benefit to hundreds of millions of people. This will provide certainty of supply for Fishy Filaments’ end-markets, and has the potential to enable the delivery of thousands of tonnes of high quality raw materials to customers around the world every year.

Investors interested in the Fishy Filaments fundraise can find out more at https://www.crowdcube.com/fishy-filaments

For more information on Fishy Filaments, visit: https://fishyfilaments.com

Media Enquiries/Interviews:

Ewan Davy/Emily Brotherton/Rachael Whitson

Absolute PR and Marketing

Tel: 01392 680 740

Ewan@absoluteprandmarketing.com / Emilyy@absoluteprandmarketing.com

About Crowdcube

Crowdcube is Europe’s largest private market investment platform, connecting companies with retail investors. It was born out of the belief that there should be more options for entrepreneurs to raise capital and that retail investors should have access to an asset class they have traditionally been closed off to.

Crowdcube has raised over £1.4bn for over 1,300 businesses that include Monzo, Revolut, Qonto and BrewDog.

About Fishy Filaments

*The building of the fully automated fishing net recycling plant prototype at Fishy Filaments’ Newlyn base is part-funded by the UK Government through the UK Shared Prosperity Fund. Cornwall Council has been chosen by Government as a Lead Authority for the fund and is responsible for monitoring the progress of projects funded through the UK Shared Prosperity Fund in Cornwall and the Isles of Scilly.

Funding history

Fishy Filaments has previously succeeded in raising a total of £443,000 through two public Crowdcube rounds and has also raised an additional £150,000 from existing investors.

Background

Working closely with Cornish, Newlyn Hake fishing fleet to maintain the quality and traceability of its supply chain, Fishy Filaments has proven that it can collect and profitably recycle end-of-life waste monofilament fishing nets into ultra-low carbon raw materials for 3D printing and advanced manufacturing, delivering social and environmental gains.

This is made possible through Fishy Filaments’ innovative chemical free process which cleans old nets to a near zero degree of contamination, transforming this problem waste into an economic asset.

Using only water and energy, Fishy Filaments’ proven recycling process has a significantly lower environmental impact than traditional plastics manufacturing, cutting CO₂-equivalent emissions by 97-98% compared to virgin Nylon 6. This makes it highly attractive to manufacturers.

The output is a traceable, low-carbon supply of high-value engineering-grade nylon 6-based materials, which can be recycled, enabling closed loop manufacturing and a circular economy. Fishy Filaments delivers on this by taking back production waste from clients to be recycled back into its production line, minimising waste and the carbon impact of the whole cycle.

Helping to reduce marine pollution domestically, and with the potential to do so globally, Fishy Filaments works with fishing fleets to provide them with a zero-cost disposal route for their gillnets.

This ‘lifecycle of the net’ narrative is proving highly attractive as a marketing message for producers of homewares such as Philips Lighting, and for fashion and accessories producers drawn by both the attractive translucent blue/green colour of Fishy Filaments’ Porthcurno line, and the carbon accounting story.

Its advanced, high value, 0rCA® family of materials are blended to include carbon allotropes such as carbon fibre or even graphene. These are attracting significant interest from advanced engineering customers including the automotive manufacturing sector.

Proven as a successful revenue generating business with multiple repeat customers, including household names such as Philips Lighting, and with a global distribution agreement with Fillamentum for its 3D printing filaments, Fishy Filaments has created a model that is profitable on a per kilo basis, enabling future scalability and commercialisation.

Fishy Filaments long-term goals

Fishy Filaments’ mission is to cut carbon emissions, delivering nation-scale impact, through the development and deployment of plastics recycling processes and the supply of recycled materials. Its goal is to save 2m tonnes of CO₂ equivalent annually, measured and attributed to Fishy Filaments’ business activities, without third party offsetting.

Having developed a prototype plant that can be delivered in a 40ft shipping container to hard-to-reach parts of the world, Fishy Filaments’ long-term goal is to provide a global solution that will help to prevent the 200,000 tonnes of netting that is annually burnt, buried or discarded around the world each year.

Operational in less than a day, and requiring only water and power, its plant technology is being developed to deliver scalability, providing fishing communities with a valuable end of life net disposal route.

Potentially bought by entrepreneurs, governments, harbours, fishing fleets or NGOs who will collectively manage the recycling of thousands of tonnes of monofilament netting each year, the chemical-free monofilament net recycling plants will not only provide jobs, and a source of materials for local markets, but a direct feed to Fishy Filaments.

Underpinned by off-take agreements, providing a guaranteed price for recycled materials, the scalability of this approach will enable Fishy Filaments to meet growing customer demand for its products internationally. It will also provide a source of reliable and traceable materials, including recycled nylon, for its advanced, high value, 0rCA® family of materials, delivering world-beating low carbon impact.

Find out more about Fishy Filaments Limited on their member profile page here

Member-created content 1 year ago | From members