Following on from last week’s introduction to power skiving, how does it compare to traditional gear manufacturing methods?

The technology behind power skiving has been around for over 100 years. It was the advent of more specialised equipment, such as 5-axis machining centres, that paved the way for the increased utilisation seen in power skiving today.

It is a fact that new technologies need to offer advantages over current, older methodologies. Alongside these advances are customer’s increasing manufacturing requirements, needing more precise gears in shorter lead times with higher flexibility between cycles.

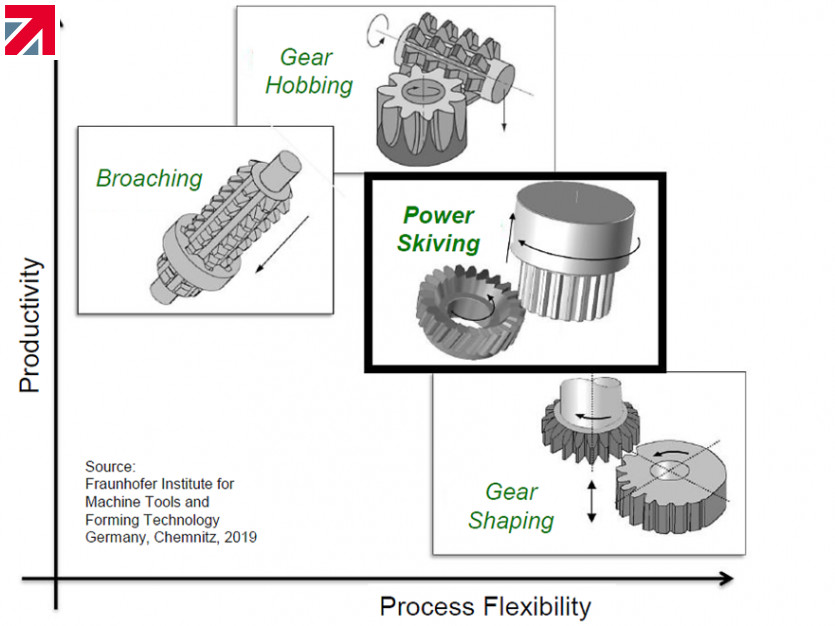

Power skiving provides further advantage compared to other gear production processes such as hobbing, broaching, or shaping. Functioning as an excellent middle-ground, it offers an ideal blend of productivity and flexibility for any project. Please see 'Productivity vs Process Flexibility' graph for reference.

Other benefits power skiving provides include:

- Less required machinery saves on floor space and overall investment costs

- More flexibility with processes, quicker workpiece changeovers, and shorter machining times offer higher machining economy

- Ability to dry machine parts reduces cost of lubricant and any potential environment impact

- Can perform both roughing and finishing in one cycle, whilst compensating for any distortions with tool path corrections

We are continuing our deep dive into power skiving next week, where we will be looking into our other investments to make the most of this technology.

Please do keep up to date by subscribing to our newsletter and follow our LinkedIn for more updates.

Find out more about R E Thompson on their member profile page here

Member-created content 3 years ago | From members