Lubrication critical to the life of pins and bushes on loading shovel attachments

Daily or Regular lubrication is a recommended maintenance practice to the pins and bushes on a loading shovel attachment if you are to maximise their operating life.

Frequent lubrication has two key benefits

- It maintains the correct lubrication film to minimise wear

- Any contamination within the pins and bushes is purged. If debris (dust, dirt, sand or moisture) are allowed to get into these components they will form an abrasive compound. This has the potential to reduce bearing life, which ultimately will increase maintenance cost and downtime.

Improper or Poor Lubrication Costs

The cost of improper lubrication can be evaluated as

- Increased costs on replacing worn parts

- Lost production time due to unexpected break downs and repairs

- A lower resale value on a badly worn / poorly maintained attachment

- Additional costs if excess lubrication is applied

The Problem of Daily Manual Lubrication

- To manually lubricate the grease nipple points on a loading shovel attachment can often take fifteen minutes per day.

- Irrespective of training not all operators will lubricate the pins and bushes correctly

- Some loading shovel pins and bushes need to be lubricated in more than one position to ensure lubricant is evenly distributed and components are protected under heavy load

- In poor weather conditions manual lubrication isn’t easy to complete

- By there very nature lubrication points can be in hard to reach areas which requires an operator to climb over a machine ( with all the health and safety implications )

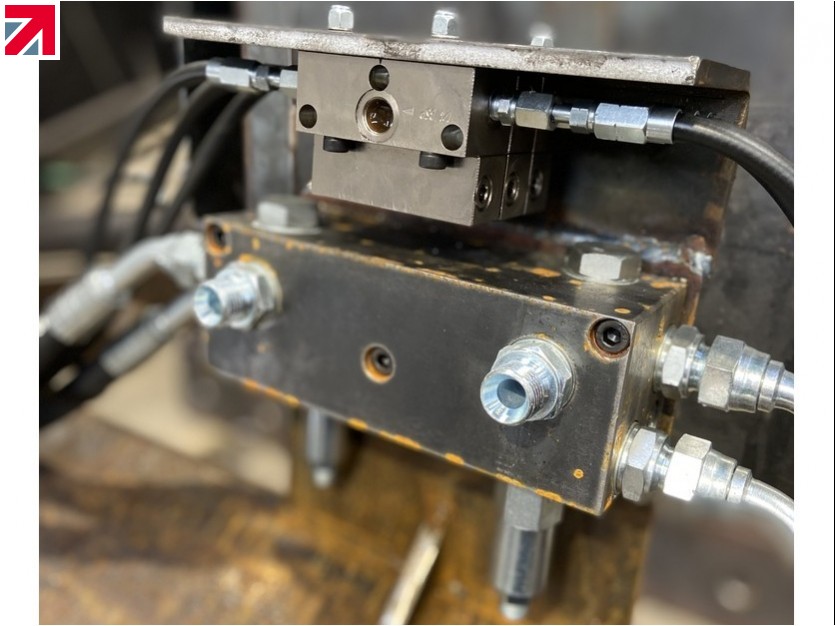

The Benefits of BA Caulkett Automatic Lubrication

- Avoid the issue of operators incorrectly lubricating pins and bushes

- Gain additional productivity as operators simply need to ensure the lubrication holder is filled to a minimum level, thus potential saving 15 minutes a day.

- Reduce grease consumption by delivering the optimum amount required

- The automatic lubrication system works irrespective of the weather (guarantee that the bushes and pins are greased everyday)

- Eliminate the practice of climbing over machinery to lubricate

Automatic Lubrication Beneficial For Daily or Weekly Lubrication Points

BA Caulkett recommend automatic lubrication for daily or weekly lubrication points. Manual lubrication for smaller / lower load equipment with fewer lubrication points or where the loading shovel is suitable for extended lubrication intervals ( e.g after 250 hours)

If you would like more information on Automatic Lubrication for loading shovel attachments then please call 01440 706 429.

If you think a bespoke High Tip Bucket might be required then why not visit the factory and discuss your requirements with our engineering team.

To see the complete range of loading shovel attachments in action click here

Find out more about B A Caulkett Limited on their member profile page here

Member-created content 5 years ago | By Made in Britain