Currently, a vast majority of steam systems still undergo manual inspections, possibly every 6 months, and annual steam trap surveys. That leaves a large window for things to go wrong: leaking & blowing traps, water hammer in the system, deterioration of pipes, etc. Problems are expensive and current prices forecast the cost of one leaking trap over a 6-month period to be approximately £680 ($862). Scale that to a site with 1,000 traps, an estimated 10% failure rate, and that would cost around £68,000 ($86,200) in losses.

Unfortunately, manual inspections put engineers in a reactive position. And in many situations, the big catalyst for change or the need to update systems, is only prompted by a big loss or malfunction. That’s why it’s crucial to understand how monitoring and dashboard analytics can move you from reactive to proactive. Let’s look at how these tools can drastically change the work week for engineers overseeing steam systems.

Monday: INSTALLATION

Today, 250 steam trap monitors & LoRaWAN Gateway are being installed alongside DCO Systems. Because you have a mix of traps throughout the site, you had the Easy STM for drip & line traps, Flex STM for those needing flexible configuration, and Ultra STM for high process traps, deployed. Clip-on mounts and extension cables meant these were deployed by your team with ease.

Tuesday: COMMISSIONING

All monitors are programmed to connect to the LoRaWAN Gateway and you now have access to DCO’s DiscoverRA dashboard. The ‘Map locations of device’ has been populated with GPS coordinates, known asset tags, photos, notes and annotations that were collected in relation to each trap where monitoring was installed.

Wednesday: UP AND RUNNING

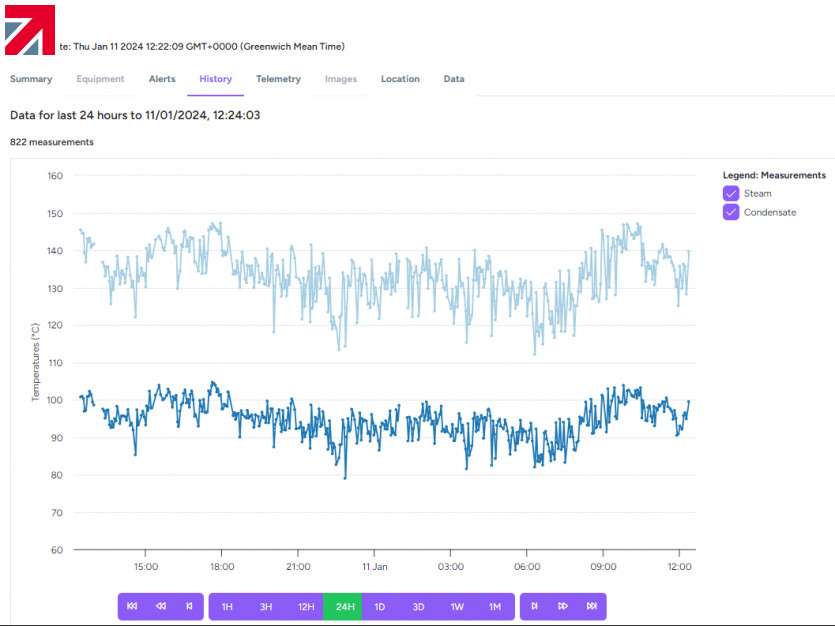

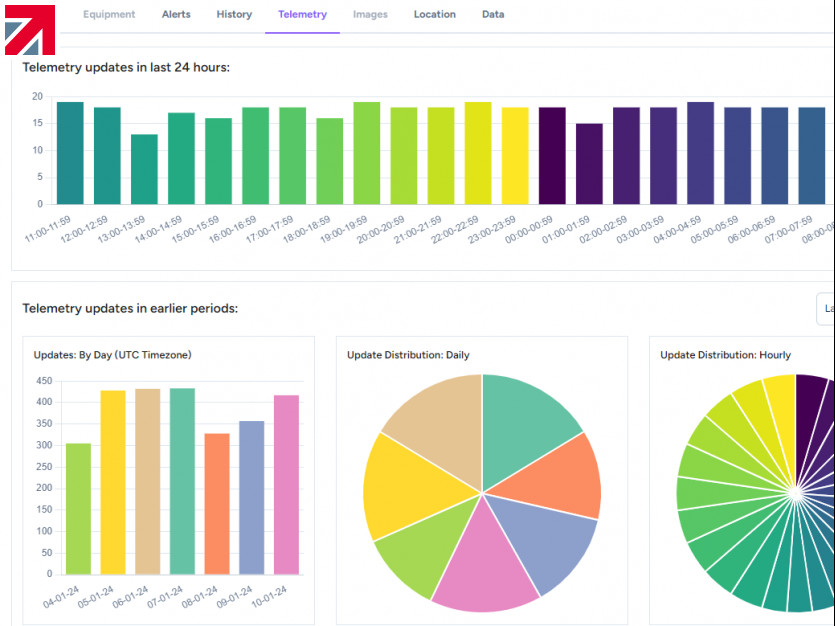

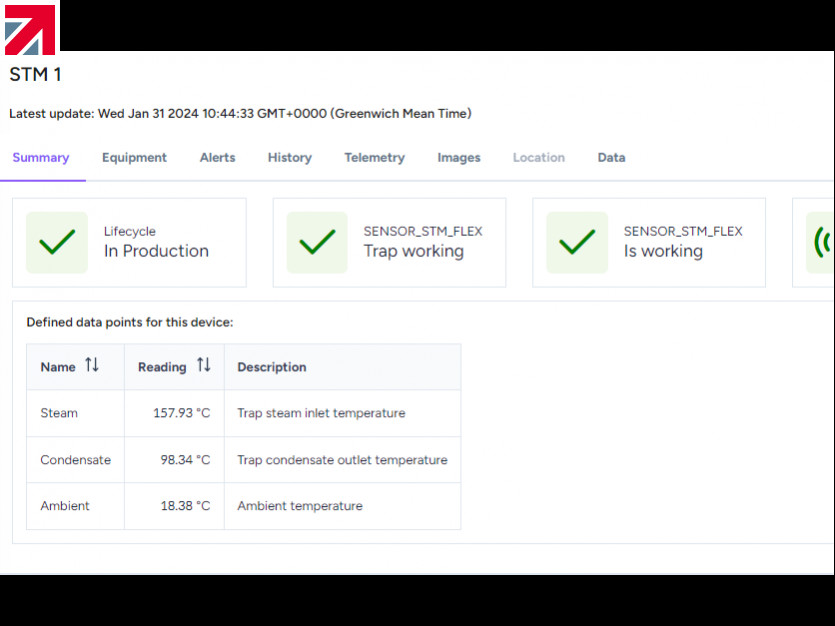

Logging into DiscoverRA, you can see dual temperature measurements for steam and condensate, plus orientation, vibration, ambient temperature, humidity, and pressure conditions. Looking at Building 2, you select STM 1 and can see the granular measurements over the last 24 hours. The ‘History’ tab will be useful when your team begins trialling and testing improvements.

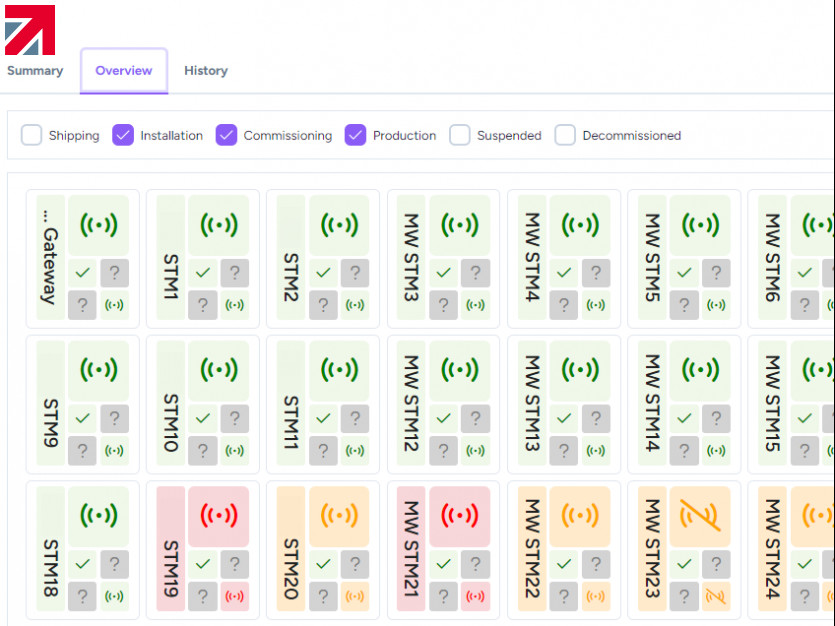

Thursday: FAULTS RAISED BY LIVE MONITORING

An alert on your phone has notified you that STM 19 and STM 21 at Building 5 are both malfunctioning. The site is a 45-minute drive away. You can see from the data that the temperature has risen considerably. This is a characteristic of a leaking trap.

Friday: FAULTS RESOLVED

You send an engineer with the right tools to address the problem. By fixing the problem and stopping the small leaks on Day 1, as opposed to 6 months later, this has saved your company approximately £675 ($856) per trap. Furthermore, over the weekend, everyone on the engineering team can see the same data as you and you know that all 250 traps are being carefully looked after.

In conclusion, you’ve saved the company a lot of money, decreased driving time from site to site and you now have 100% visibility on all your traps at all times. You are now freed up to focus on improving processes and prioritising other sustainability projects. Don’t be in the dark when it comes to your steam systems. DCO Systems’ steam trap monitoring solutions are built to give you a proactive edge and the dashboard is designed to give you the data you need. Your monitoring project is possible today. Visit dcosystems.co.uk to learn more.

Find out more about DCO Systems Limited on their member profile page here

Member-created content 1 year ago | From members