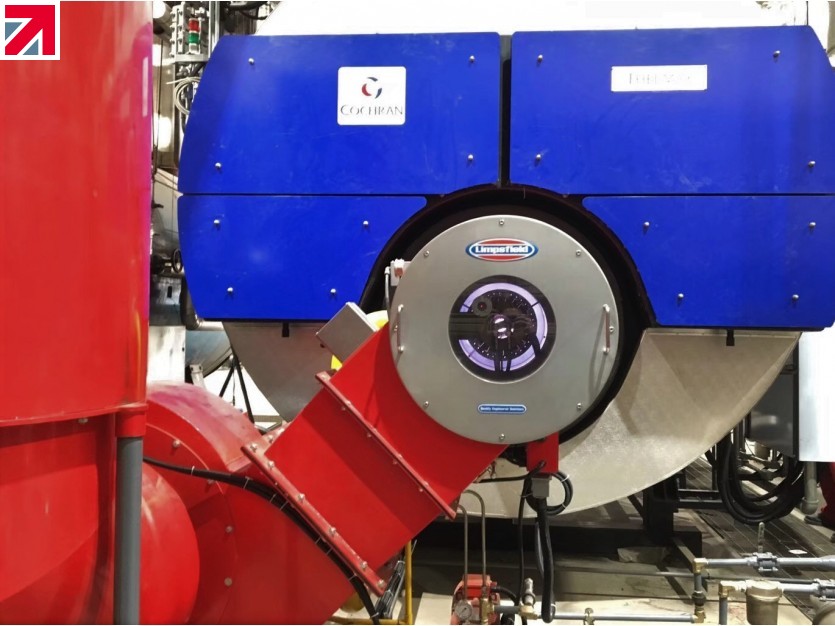

Limpsfield burner was installed approx. 2 years ago at the largest semiconductor manufacturer, located in China, Tianjin. Our burner was designed to achieve 60-80mg/Nm NOx @3% O2 with minimum 8:1 turndown ratio. The end customer has expressed multiple times how pleased they are with the provided equipment, the burner performance and it`s reliability.

More recently, the NOx emissions rules have changed and the existing boiler/burner plant must now meet sub 30 mg/kWh NOx emissions (<15 ppm).

The customer was very happy to learn that they can re-use most of their existing burner, fan, FGR (flue-gas recirculation) equipment and with minimal modification to the internals of the burner they will be able to reach the required NOx emissions.

Because of our simple Ultra-Low NOx burner head design, the whole burner retrofit project was straight forward and smooth and the boiler was online within 3 working days.

After the retrofit the burner can meet the 30mg/kwh NOx limit and keep the O2 levels at 3.5% across the whole firing range. The combustion efficiency has not be sacrificed despite running at ultra-low NOx emissions.

Project achievement:

1. Burner meets sub 30mg/kwh NOx @ 3.5% O2.

2. Burner can still fire diesel oil as a back-up.

3. Easy to maintain – Ultra Low NOx burner has the same design as our standard burner

Find out more about Limpsfield Combustion Engineering Co Ltd on their member profile page here

Member-created content 4 years ago | From members