The basic principles of metal detection and x-ray inspection are relatively straight forward. In understanding how each system operates we can achieve a greater understanding of how using detectable products can be beneficial.

There are three main groups of metallic contaminants that can be picked up by a metal detector. Ferrous, nonferrous, and stainless steel. Ferrous contaminants are the easiest to detect as they are electrically conductive and magnetic. Non-ferrous contaminants are not magnetic, however they offer good conductivity. The most difficult to detect are stainless steel contaminants as they tend to be non-magnetic and possess poor conductivity, meaning that metal detectors are able to reject a smaller size of ferrous material than that of stainless steel.

The newest multi-spectrum metal detectors can achieve very high levels of sensitivity. In order to maintain the level of detection required, regular service and testing of any detection system in use should be in place and documented by a professional. An x-ray inspection system is required to detect non-metallic foreign body contaminants such as stone, bone, glass, and ceramics.

An x-ray inspection system works by passing low energy x-rays (gamma radiation) through the product, which then passes through the detection array. The differences between the amount of energy absorbed by the product and the contaminant is then calculated and analysed by the computer.

Through a calibration sequence the system will have learnt the profile of the product passing through, meaning that it knows what a good product looks like as well as the different variations that may occur in a product with no contamination. Therefore, it can detect any anomalies and remove contaminated or otherwise unsuitable product. X-ray systems can also capture and store an image (radiograph) of where the contaminant has been found so that it can be easily investigated.

Whilst an x-ray system can detect ferrous, non-ferrous, and stainless steel contaminants they can also detect stone, bone, glass, and ceramics as these are typically a higher, contrasting density to most food products. However, X-ray inspection systems may have trouble detecting items with a similar density to the product such as fruit stones, insects, low-density plastics, stalks, string, and wood.

Through HACCP analysis, audit, incident, or by accident - you may become aware of an item that represents a foreign body contamination risk. If that item is essential to your process and it is not possible to remove it - it should be considered whether that item can be made from detectable materials; but it is important to be aware that not all detectable materials are the same.

The first detectable products were used in food production in the late 1980's and featured iron filings embedded within, or stuck to, high risk items in order to trigger the end of line metal detector should they inadvertently be introduced to the product. Today’s approach is much more scientific, refined, regulated, and researched. The ferromagnetic additives used have an ultra-fine particle size and carry full FDA and EU food safety approvals. Their dispersion in carrier polymers and rubbers should be homogeneous and at a level that does not compromise the mechanical integrity of the material.

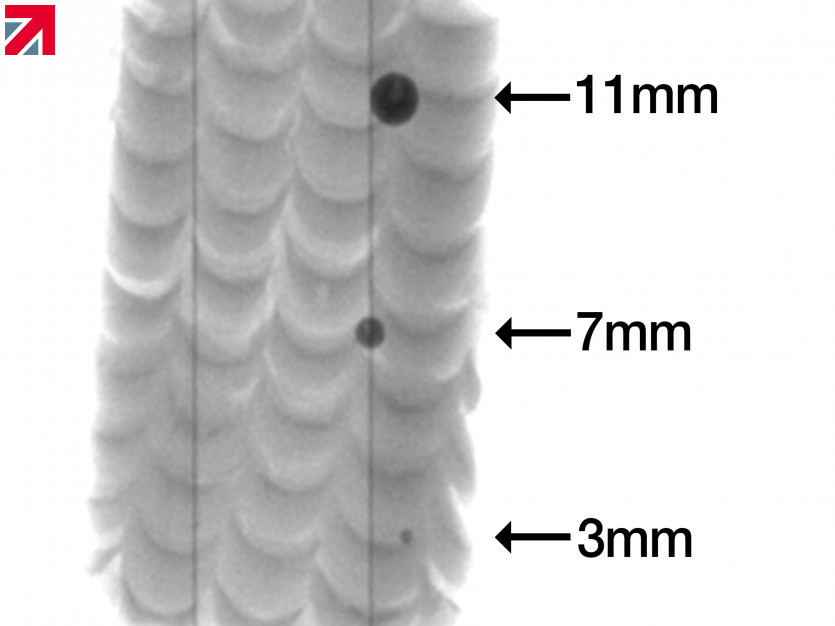

Ferromagnetic additives are used to make a plastic or rubber detectable for the purpose of metal detectability, but food safe ultra-dense additives must be used to achieve good x-ray contrast performance. When these additives are introduced to polymers at the correct ratios, x-ray inspection systems can detect fragments as small as 3mmس.

In 2009 BST were the world's first company to develop a high performance dual detectable polymer. This is a plastic compound that contains the appropriate levels of both ferromagnetic and high density additives to trigger metal detection and x-ray inspection systems, whilst still functioning as a high performance polymer. Dual detectable products represent a huge step forward in food safety as they are safe for use in factories that may use metal detection on one product line and x-ray inspection on another, therefore saving money.

Find out more about BST Detectable Products on their member profile page here

Member-created content 2 years ago | From members