There are a multitude of different plastics available with different features suited to different applications. It comes to a point where choosing the right one for a given project can be overwhelming, especially for those with limited knowledge or experience in the matter. Each material has trade-offs when it comes to cost, strength, flexibility, and surface finish. We must take into consideration not only the specific application of the material but also its environment as this will impact your decision also.

Plastics are always changing, improving, adapting with greater and more expansive mechanical properties to prove greater durability and more desirable results. Some plastics are even available with modifications to even more accurately suit a given application such as increased strength or heat resistance. It is, then, increasingly difficult to know which plastic to choose over another, and with so many options available now, it can even be hard to know the difference between one plastic and another.

It is my hope that the following comparisons between different plastics intended for similar uses will help to clear things up a little and aid in your decision making process.

Aviation, Automotive, Telecom - PEEK vs PPSU

When it comes to high-performance thermoplastics, both PEEK (Polyetheretherketone) and PPSU (Polyphenylsulfone) offer excellent thermal properties and dimensional stability. These plastics have much in common and are often used in similar applications, however, each one possesses unique properties that the other does not and so it is important to understand the differences in order to choose the right plastic for your application.

PEEK provides greater compressive and tensile strength than PPSU as PPSU is prone to stress-cracking if not properly treated and maintained throughout the process. However, PPSU has a greater resistance to indentation than PEEK and would be a better choice for water and electrical resistance.

Medical - PPSU vs POM

POM (Polyoxymethylene) is often used in medical and healthcare applications due to its resistance to cleaning disinfectants and solvents. That said, POM does manage to retain its properties and appearance for the first few hundred sterilisations, but after that it fails in appearance and then continues to lose its properties from there. This is why PPSU (Polyphenylsulfone) has started to be considered as a replacement for POM as it has proven to be a higher performance material. After repetitive sterilisation, PPSU has proven to retain its appearance and dimensional stability much longer than POM.

Mechanical Parts - POM vs PA

PA (Polyamide) is commonly referred to by the more popularised name ‘nylons’. These titles cover a range of material types as it can be paired and altered to provide a wide range of properties. It is for this reason that PA (or Nylon) is commonly used to make mechanical parts. PA is highly resistant to wear and is able to maintain its properties at higher temperatures than other plastics. Unfortunately though, it does have a tendency to absorb moisture over time.

This is where POM (Polyoxymethylene) comes in. POM is also widely used to produce high precision parts as an alternative to metals as it provides good dimensional stability. Both these materials have good sliding properties, low wear, good temperature range but POM also has the added bonus of low moisture absorption. However, POM does have a tendency to degrade with alkali and chlorine.

High Voltage - PA vs PBT

PA (Polyamide) and PBT (Polybutylene Terephthalate) are both used in high-voltage environments. They both have good chemical resistance, are strong, and have good wear resistance; so which is actually better suited to the application?

Well, initially you may think that PA is the superior plastic, as in dry conditions it shows better values than PBT across the board. This is largely due to the fact that both extruded and cast Nylons (PA) can be modified through fillers to enhance its properties. However, due to the higher moisture absorption rate, PA loses its dimensional stability, bringing it down to the level of PBT statistics.

The low moisture absorption rate of PBT means that it is able to retain its properties even in hot, moist environments which would suggest that perhaps PBT is more suitable for use in humid, high-voltage environments than PA.

Food Industry

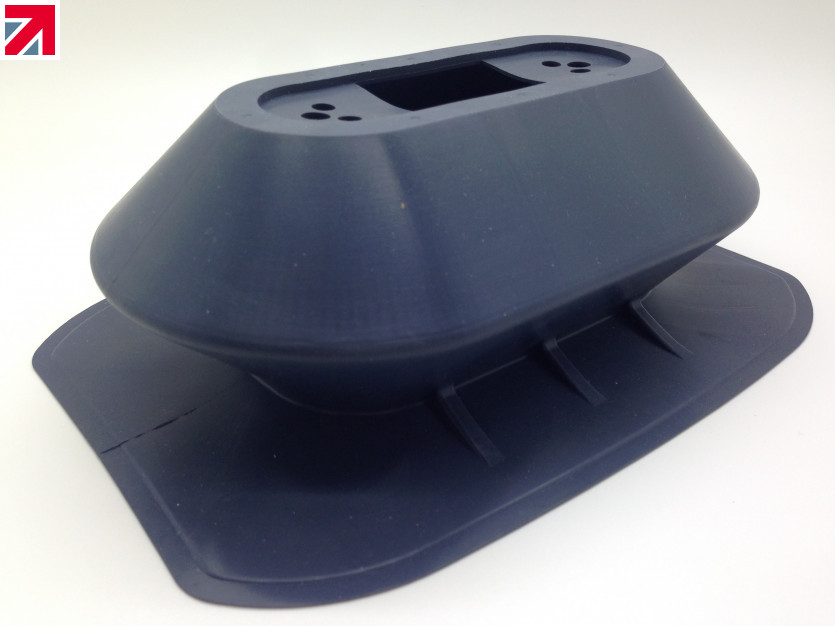

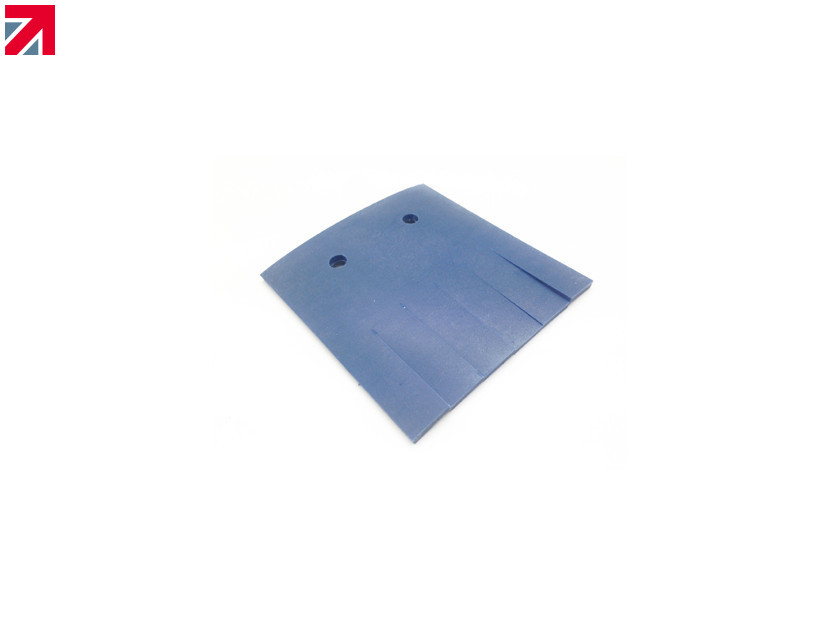

When it comes to using plastic materials in food industry applications, there are many factors worth considering. Depending on where and how you require the material to function, properties such as Strength, Elasticity, Chemical Resistance, Heat Resistance, Moisture Absorption, Food Contact Compliance, and Detectability will play a vital role in choosing the correct plastic for the job.

If, for the sake of this document, we look at the two food industry specific attributes (Compliance and Detectability) all of these materials would come highly recommended. PPSU (Polyphenylsulfone) is FDA compliant and the rest are both FDA and EU compliant. PPSU (Polyphenylsulfone) is X-Ray Visible and PA (Polyamide) is Metal Detectable. POM (Polybutylene Terephthalate) and PBT (Polybutylene Terephthalate) are both Metal Detectable and X-Ray Visible, and PEEK (Polyetheretherketone) can be modified to be dual detectable too.

It then comes down to the environment and specific role of the plastic to narrow down which would be better suited than another.

Summary

It is clear that all these materials bring something to the table.

In regards to strength, you can’t really go wrong with any of the materials mentioned above, the only outlier would potentially be PA (Polyamide) as it loses its strength under certain conditions such as in hot or damp environments.

If you require elasticity from your plastics, PEEK (Polyetheretherketone) and PA (Polyamide) have good elasticity and therefore provide greater compressive strength. Whereas PPSU (Polyphenylsulfone), POM (Polybutylene Terephthalate), and PBT (Polybutylene Terephthalate) do not and are therefore better suited for wet environments and electrical/high voltage applications.

Although POM is known to degrade with alkali and chlorine, the remaining plastics all exhibit good chemical resistance.

As has been previously mentioned, the properties of PA quickly degrade when exposed to heat. POM has a better functional range of -40° to +140° and the rest have excellent heat resistance.

Finally, moisture can cause an issue for PEEK and more so for PA but PPSU, POM, and PBT all have a low moisture absorption rate. This means they are less likely to lose their properties or degrade in moist or wet environments.

If you have any questions or queries about specific needs and requirements or questions about the materials in general, please don’t hesitate to contact our sales team for more information on 01302 775208 or email us at sales@bst-detectable.com.

Find out more about BST Detectable Products on their member profile page here

Member-created content 2 years ago | From members